We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When I wrote my posting on how hide glue is made last Dec. 5, I knew I had pictures from the Milligan & Higgins hide glue factory, but I couldn’t find them. Now I have, so I thought it would be a good idea to share them with you.

Part 1 • Part 2 • Part 3 • Part 4

There’s no point is repeating everything I said in the original posting. You can find it easily just by going back to my posting on Dec. 5, 2016, or even easier, type in “hide glue” in the Flexner on Finishing search box on this blog’s front page and “Hide Glue – Part 2: How it’s Made” will come up.

So here are the pictures with captions.

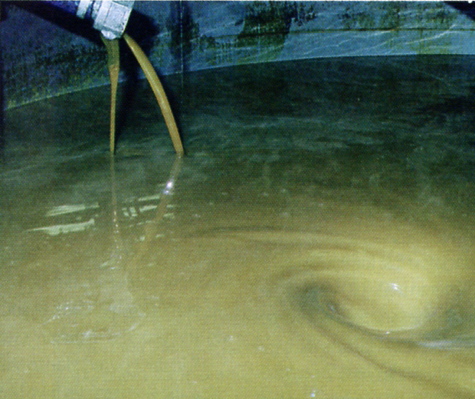

After the leather scraps have been washed, soaked in lime, washed again and neutralized, they’re put into a tank and cooked in water to extract the glue. Each cooking produces a lower-gram-strength glue.

The dilute glue solution is then filtered and poured off into another tank where most of the water is vacuum evaporated.

The concentrated glue is then chilled and run through an extruder, where the solid glue is shaped into “noodles” and then dried.

The spaghetti-shaped glue is broken up into small chunks.

Then it’s ground to its final shape.

To determine the gram strength of the glue, a 1/2-inch diameter plunger is pushed 4 millimeters into the surface of a 12.5% solution at 10 degrees Centigrade. The amount of weight in grams required to accomplish this is rounded off to the nearest “midpoint,” is the gram strength of that batch of glue.

– Bob Flexner