We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Mixing liquids. Just as all finishing products that thin with water can be mixed, so can all finishing products that thin with mineral spirits (paint thinner). Here I’m adding some stain of one brand to some polyurethane of another to make a “varnish stain,” a stain that can be left a little thicker on the wood or over another coat of finish.

Discover what finishing products work well together.

I’m sure you’ve come across cautions in woodworking books and magazines instructing you to “use a compatible product” – stain, filler, glaze, finish – and you’ve wondered, “What is compatible, and what isn’t?”

The phrase, “use a compatible,” is a “cover-my-behind” dodge used by authors who have little understanding of finishes. If you follow their procedures and then have problems, it must be your fault for using an “incompatible” product. The burden is on you to know what is compatible and what isn’t.

So what is compatible with what?

Three entirely different situations can be referred to by the word “compatible:”

• Mixing liquids with liquids;

• Applying stains, fillers, glazes and finishes; and

• Coating over an existing finished or painted surface.

As I explain each of these, you will see that the issue of compatibility has been greatly exaggerated. In most cases, it’s obvious which liquids mix. Almost any finishing product can be applied over any other as long as the previous is dry. And almost any finish can be applied over almost any old surface as long as it is clean and dull.

Mixing Liquids

Mixing finishes. Almost any finishing product can be applied over any other as long as the “other” is dry and the product you’re brushing doesn’t dissolve and smear the existing. I applied a water-soluble dye to this mahogany. Then I applied a thin shellac “washcoat” as a barrier so the water-based paste wood filler I used wouldn’t dissolve and smear the dye. After the filler dried, I brushed polyurethane. I alternated water-based, alcohol-based and mineral- spirits-based without any problems because each previous product was dry.

Most products you use in finishing (or painting) are water-based or mineral-spirits-based. All water-based mix successfully, and all mineral-spirits-based mix successfully. But the two cannot be mixed together.

Wax mixed with varnish works well only if you wipe off all the excess after each coat, just as with wax mixed with oil.

It’s easy to know when two products don’t mix: they separate. For this reason it’s wise to use a glass jar for mixing if you have any question, so you can see what’s happening.

Applying Finishes

Clean and dull. The rule for coating successfully over an old surface is that the existing surface has to be clean and dull. So before applying another coat of finish to this 25-year-old lacquered cabinet door, I washed it with household ammonia and water. Ammonia cleans kitchen grease and dulls most finishes in one step.

Almost any finishing product – stain, filler, glaze, finish – can be applied successfully over any other finishing product, except wax (including residue wax from paint strippers), as long as that product is dry. This includes every finish over boiled linseed oil, and water-based finishes over oil stains. You might need to give the oil-based product several days or a week to dry in a warm room, but once dry every finish will bond fine without problems.

Think of painting a piece of furniture you finished several years earlier with oil. You wouldn’t hesitate using a water-based paint.

There are several fairly uncommon exceptions to this rule.

One is brushing a product that contains the solvent for an underlying stain. For example, if you brush a water-based finish over a water-soluble dye that doesn’t contain a binder, you will smear the dye and cause the coloring to be uneven. The same is true if you brush lacquer over a lacquer stain. The lacquer-thinner solvent in the lacquer will dissolve the stain and your brush will smear it.

But there’s no problem spraying because no smearing can occur.

Coin test. The easy way to test the bonding of a finish is to scratch it with the edge of a coin. If you can scratch off a layer (as is the case here) rather than merely dent it, the finish isn’t bonded well.

If you need to brush a water-based finish over a water-soluble stain or lacquer over a lacquer stain – to match a color, for example – you can apply a barrier coat of shellac or varnish in between. Shellac is usually the better choice.

Another exception is applying lacquer over varnish, though I don’t know why you would do this. The lacquer thinner in the lacquer may cause the varnish to blister. Spray light coats to begin with or apply a barrier coat of shellac.

Also, high-performance coatings such as conversion varnish, polyester and UV-cured finishes have special rules for application. Few readers of Popular Woodworking use these finishes, but if you do, be sure to follow the manufacturer’s instructions.

Coating an Old Surface

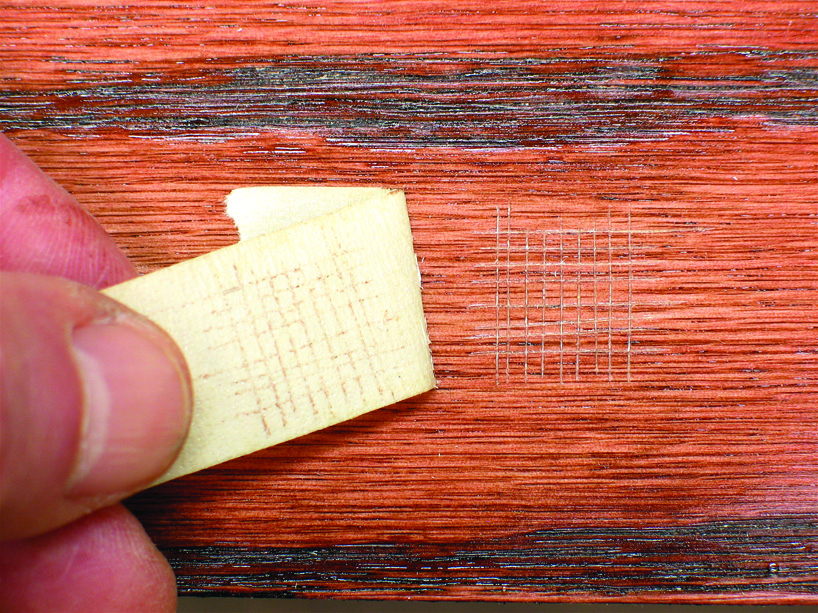

Masking tape test. A more accurate method for testing adhesion is to make a half-dozen cuts into the finish in perpendicular patterns using a razor blade, with each cut about a millimeter apart and an inch long. Then press masking tape over the cuts and lift it quickly. If the edges of the cuts remain fairly clean, as they are here, the bond is good.

Almost any paint or finish can be applied over almost any old paint or finish as long as the surface is clean and dull.

It’s pretty obvious how bonding problems could occur if you apply paint or finish over a greasy or waxy surface, or over a surface that is covered with dirt (such as a deck). So the first rule is that the surface be clean.

Because there are two types of dirt, solvent-soluble and water-soluble, there are two types of cleaner: petroleum distillate (mineral spirits and naphtha) and water, or soap-and-water. Petroleum distillate won’t remove dirt on a deck, and water won’t remove grease or wax.

Some strong cleaners, such as household ammonia and TSP (available at paint stores), will usually remove both, however. Also, abrading the surface with sandpaper, steel wool or an abrasive pad will usually remove both types of dirt, along with the top surface of the coating – paint or finish.

The surface also has to be dull to get a good bond. Liquids don’t flow out and “wet” glossy surfaces well. Think of water beading on a car or glossy tabletop.

You can dull any surface using sandpaper, steel wool or abrasive pad, and many times you can dull the surface adequately with one of the strong cleaners – a little household ammonia in a bucket of water or TSP in water. Depending on the paint or finish you’re trying to dull, solvent-based “degreaser” and “liquid sandpaper” also often work. It won’t hurt to try; you can always follow with an abrasive.

Besides “wetting,” the reason a surface has to be dull is to create a “mechanical” bond between the new coating and the existing one. Dullness always indicates an uneven surface containing scratches, bumps or other irregularities that give the new coating something to lock into and grip. This is sometimes called “tooth.”

There are three situations, however, where coating over an existing coating can be problematic.

The first is when using any finish that contains lacquer thinner. This solvent can cause any old coating, even lacquer itself, to blister. To avoid blistering, spray several light coats and let them dry thoroughly before spraying fully wet coats. Or apply a coat of shellac first and then still spray a light coat of lacquer to begin with. Brushing lacquer is always risky because you can’t brush light coats.

The second is when coating over a high-performance finish that has been applied in a factory or professional shop. Bonding can be weaker even with a clean-and-dull surface.

Also, water-based finish and latex paint don’t bond as well to existing coatings as do solvent-based paint and finish.

Testing for a Good Bond

So you need to know how to test for a good bond. There are two ways.

The easiest is to press the edge of a coin into the newly applied coating after it has fully dried and drag the coin a few inches. You should just dent the surface, not separate the newly applied coating.

Another method is to use a razor blade to make perpendicular cuts into the coating about a millimeter apart and an inch long. Then press masking or other sticky tape over the cuts and pull it up quickly. The cleaner the cuts remain after removing the tape, the better the bond.

Of course, you should perform both these tests on an inconspicuous area or, better, scrap wood.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.