We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

If you build traditional casework with traditional joints and fasteners then you already know the local hardware store is of little use when you need some 4d rosehead nails.

Lucky for us, there’s the Internet, which can be a pretty good hardware store.

Several readers have asked about what fasteners they should keep in stock in their shop. The answer is, of course, it depends on what you build. The following is a list of what I always keep on hand in my shop and what I use each fastener for.

Cut Nails from Tremont Nail Co.

• Fine finish nails, 6d (2”). For assembling full-size casework components in 3/4” and 7/8” material.

• Fine finish nails, 4d (1-1/2”). For assembling casework, especially toenailing shelves and dividers into dadoed case sides. Or for nailing from the outside of a carcase into a frame that is dadoed into the case.

• Clinch rosehead standard, 4d (1-1/2”). For attaching backs and bottoms to cases (the head of the nail adds holding power). I also use these to attach web frames to the side of a case.

• Fine cut headless brads, 2d (1”). For attaching small mouldings.

• Fine cut headless brads 4d (1-1/2”). For attaching large mouldings.

Slotted Flat-head Wood Screws in Steel (I get mine from Blacksmith Bolt)

• No. 8 x 1-1/2” for assembling full-size casework pieces – attaching 3/4” or 7/8” boards to one another.

• No. 8 x 1-1/4”, also for casework when 1-1/2” is too long.

• No. 8 x 1” for attaching 1/2” and 3/8” backs and bottoms.

• No. 8 x 3/4” and No. 8 x 5/8” for attaching full-size hardware (e.g. strap hinges) to the exterior of casework.

A couple caveats to the above list: This list doesn’t really help you with attaching hardware such as hinges. I approach this on a project-by-project basis and always order extra hardware (especially when dealing with brass screws). If you use one hardware supplier a lot – I use Horton Brasses, for example – then you’ll soon get used to their fastener sizing and stock up on the stuff you use all the time.

Oh, and I’m no fool. I have a big box of No. 8 x 1-1/4” drywall screws for assembling jigs and screwing stuff down to the bench when necessary.

— Christopher Schwarz

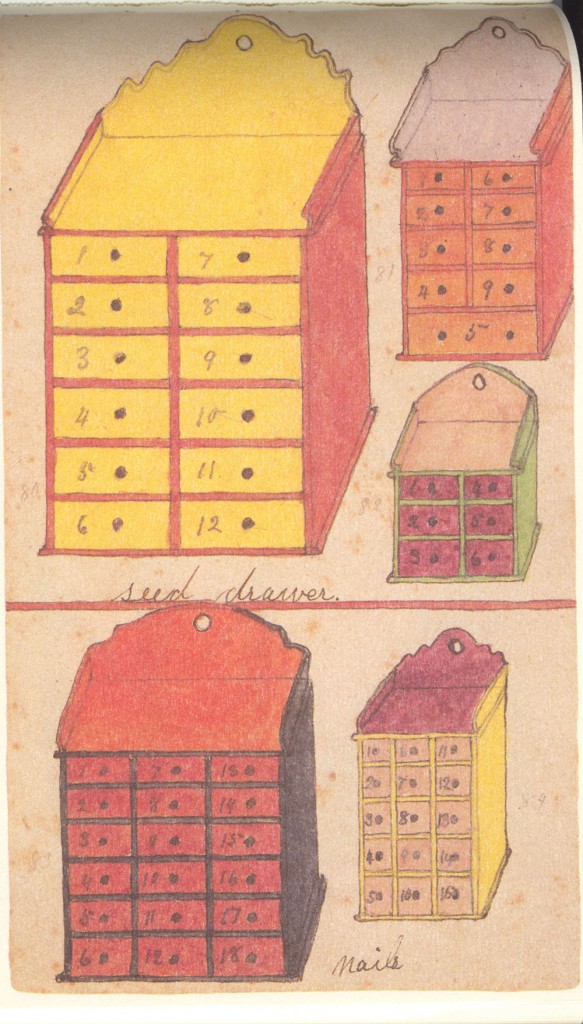

As you can see, I keep all my screws in my family’s old spice cabinet. This works, but I have to keep my nails in a plastic tackle box. This year I’m building a real “nail cabinet” based on several traditional models, including one owned by Roy Underhill. Also, you can read more posts about traditional hardware here on my blog by following this link.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I am always amused at why you stick with common or

philips screws?

I much prefer the robertson square drive, when possible.

In fact stockroom supply carries a combo square/phillips

drive screw for those who still prefer phillips.

Sometimes depending on screw size there is very little

choice but give the choice I will use roberston.

For those of you not into warehousing hardware, Tools for Working Wood carries project quantities of Tremont nails.

http://www.toolsforworkingwood.com/store/dept/CNL

Chris,

Why don’t you talk Tremont nail and Blacksmith Bolt into supplying a starter selection like McFee does with square drive screws?

Wayne Merhoff

Hi Chris,

And for the scavenger in all of us, don’t overlook discarded items from the curb, craigslist, or other cheap/free sources. Great source of screws, hardware, and even some pretty nice wood. I’ve taken in several abandoned “children” in the past and re-purposes screws, hinges, handles, “L” brackets, etc. In the past year I found a painted coffee table that, when paint was removed, revealed beautiful 3/4 x 7 in x 44 in tiger oak. Currently working on reviving an Abernathy drop leaf dining table from the front porch of a craigslister. It’s walnut and turned legs still amaze me for a piece that is anywhere from 60-100 years old. Too much fun!

Paul Hasluck’s book “The handyman’s Guide” illustrates a nail cabinet. I have been thinking about building one.

Is it stronger nail nail a dadoed shelf in from the outside of the carcasse as compared to toe nailing the shelf in?

Hi Chris,

What does a traditional nail cabinet look like? Any links to online examples?