We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

If you read this blog, you are probably interested in hand tools. And if you are at the beginning of your journey, this blog entry is for you.

If you read this blog, you are probably interested in hand tools. And if you are at the beginning of your journey, this blog entry is for you.

Popular Woodworking Magazine commissioned me to make a series of 10 to-the-point videos about hand tools that try to strip away the confusion so you can get to work with a basic set of hand tools and a minimum amount of agony.

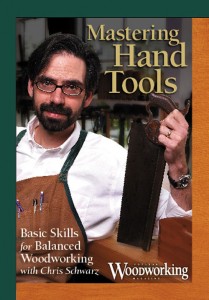

The series is called “Mastering Hand Tools: Basic Skills for Balanced Woodworking,” and it will be available both on DVD through ShopWoodworking.com and through ShopClass on Demand, the magazine’s streaming video service.

The DVD version is on sale right now before it is released on April 16. You can save $5 by clicking here. You’ll pay only $19.99.

If you want to watch the videos now, you can get a subscription to Shop Class on Demand. If you act today (Sunday, April 1), you’ll get a half-price deal that gives you six months of unlimited access to all the videos on ShopClass (and there are a lot of good ones) for $24.99. Click here to read up on the details. They also offer a free trial subscription if you aren’t ready to commit.

They’ve posted a couple of the segments from this “Mastering Hand Tools” series on ShopClass so far and I am told a new video will appear every other week until all 10 segments are up.

I am quite pleased with how this series came out. Though I really dislike being on camera, the crew put me at ease and the videos have a casual feel, like being in a one-on-one class – but they are all concise so you get what you need without a lot of blather.

So what are all the segments about? Here’s a list of what we filmed.

1. Why Learn Hand Tools? While some of this might seem obvious to those who already use them, the benefits of mastering hand tools for a power tool woodworker are sometimes surprising. They can be more accurate and faster than power tool equipment.

2. Knives, Marking Gauges and Cutting Tools: The most important hand tool isn’t the saw, plane or chisel. It’s the marking knife or cutting gauge. These are the tools that guide your saw, chisels and planes. If you can mark a clear line with these tools, you will find it easy to work down to those lines.

Picking the right marking tool can be daunting. What are the differences between a marking gauge and a cutting gauge? What’s a panel gauge? Do you really need a mortise gauge?

And when it comes to marking knives, most woodworkers get quite confused. Do you need a single-bevel knife? A double-bevel? A spear-point knife? How thick? How long? The choices can be overwhelming.

In this video, we explain what is important when it comes to marking tools. We show you how to adjust any tool so it makes the kind of line that hand tools need. It’s not hard – you just need to think like a saw, plane or chisel.

3. Handsaws: Where to Start, How to Saw and How to Become a Maestro: No matter how much you love your table saw, there are times that it is neither the safe nor smart option. For example: Knocking down rough stock in a parking lot, cutting short stock to length or cutting fine dovetails.

However, if you are smart, you can get into handsaws with only two inexpensive saws that will never need sharpening and will fool your friends at Colonial WIlliamsburg into thinking you are a handsaw maestro. The trick is to pick the right (cheap) saws and know the insider tricks.

This video will show you how to do lots of work with an inexpensive dozuki and Sharpoint saw. You’ll learn the 10 mistakes that most sawyers make and how to track a line every time (it doesn’t take years of practice). Once you have mastered these two saws, we’ll explore the traditional kit of five saws (two handsaws and three backsaws) and what these five saws can do for you if you decide to go deeper into the topic.

4. Chisels: Basic Sharpening, Paring and Chopping & Mallets: Sharp chisels make woodworking easier. They square out routed corners, they chop out waste and they can pare plugs flush with your work. But modern sets of chisels can cost as much as $250. Then you have to buy the sharpening stones (another $200) and learn how to sharpen.

What if we could show you how to take two home center chisels, some sandpaper from your shop and a $10 jig and be set for life? It’s true. You don’t have to get a PhD in metallurgy or sell a kidney to have the sharpest chisels in the city.

Once you have these two chisel sharp, we’ll show you the right way to chop and pare with these tools – chisels are the most dangerous hand tool, period. You’ll also learn about the most important tools that work with your chisels: the mallet. Learn the differences between the round- and square-headed varieties and what weight you should choose for your work.

5. Rasps: Shaping Curves and Cabrioles: Cabriole legs look intimidating, and sculptural forms (think Maloof rocker) look impossible if you are a fan of plunge routers instead of rasps. But the truth of the matter is that you don’t need a whole tool roll of rasps and carving tools to make shapely curves.

Instead, you just need one inexpensive tool – that never needs to be sharpened – and know the basic strokes to turn out cabriole legs and compound shapes with ease. Once you master this Shinto rasp, we’ll explore the traditional rasp kit of the hand-tool woodworker, including cabinet rasps, modelling rasps and rattails.

We’ll look at the difference between machine-made and handmade rasps and why it is usually worth the extra money to buy the better tool.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

The link above that says click here for 19.99 shows 26.99 on the page.

Does the DVD have everything from the indvidual ShopClass downloads? If so i guess it’s pretty long as the first 3 parts are nearly 1.5hrs long. I don’t want to order the DVD if the downloads give me more content.

Chris,

Do you know what the run time is? Thanks.

Sam

I will have to give the video a try. I agree with you on all points, especially with the sanding. One minor disagreement with the rip saw. I’m hardly a great sawyer but I found that even I can rip a board with a repectable amount of accuracy. I just don’t like the amount of time involved. Prefer the table saw and a jack plane to clean up the edge. Other than that good post.

Twenty bucks? I’ll buy two, one for myself and one for my shop teacher! He needs to learn how to think like a saw.

Screw it. I’ll buy four. You never know who I’ll meet.