We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Short of that stint living in Anchorage (yep, Alaska) from birth until I was about 2 years old, and the last seven months or so living in the Cincinnati area, I’ve lived the vast majority of my life outside of Philadelphia. You might be thinking that is the singular reason for the title of my post but you’d be wrong. While I truly enjoyed being completely immersed in the history and rich furniture culture that is available in the greater Philadelphia area, the reason for my title today revolves solely around a construction detail: through mortise-and-tenon joinery.

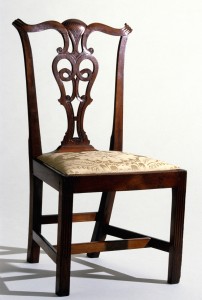

We can argue aesthetics but when it comes to joinery, specifically chair joinery, Philadelphia just kicked every other 18th-century American city’s behind. Why, you ask? Because in pretty much every other region of the country the tenons were captured in the rear legs of their chairs. This meant shorter tenons, which meant less holding power, which meant less longevity for the chairs.

Philadelphia chairs, on the other hand, were generally through-tenoned on the rear legs throughout the Queen Anne and Chippendale periods. With tenons that are brought all the way through the rear legs of a chair, you get lots more holding power because the joint is so long. Add in the fact that most of the joints are pinned and you’ve got a recipe for chair joinery that is something akin to a Sherman tank.

When you look at the size of the rear legs on a chair from the mid to late 18th century, the cross-section where the side rail meets the leg shows the legs tend to generally be about 1-1/2″ to 1-3/4″ square(ish). If you only mortise partially through the rear legs on a chair, that means you’ve got somewhere around a 1″ to 1-1/4″ long tenon. Taking the mortise all the way through brings that tenon length to 1-1/2″ to 1-3/4″ long; it might not sound like much, but it dramatically increases the surface area in the joint which means better hold from the glue.

While through-tenon joinery on chairs is not exclusive to the Philadelphia area, the preponderance of examples do come from the region. Some craftsmen from other regions included the method in their chairs – Eliphalet Chapin of the East Windsor/Hardford, Conn., area comes to mind (though he did study in the Philly area) – but those are rare.

Through mortise-and-tenon joinery isn’t the only factor that makes Philly chairs the equivalent of wooden tanks, but it is the most obvious. When you look at the construction at the front legs you’ll see some differences from other regions as well, but that’s a discussion for another Friday.

So the next time you’re wandering your favorite museum or antiques shop and you see a chair with through mortise-and-tenon joinery, chances are it’ll be from the Philadelphia area.

For a little more on 18th-century chair construction, check out this episode of The Woodwright’s Shop.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Very interesting article. Thanks!

Because I am from Philly I didn’t even need to read anything after the title in order to agree whole heartedly. In fact, if every one of your posts has a similar title I will continue to not read them yet still agree with everything you say. Okay, I will still give them a passing glance…:)

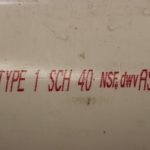

How long is the tenon on the back rail? In picture #2 it looks kind of short.

Thanks.

Still wondering why you don’t switch class times w/Glenn to do the chair panel at WIA. You’re clearly qualified for it.