We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A straight mortise-and-tenon joint requires each tenon cheek to be flat, of consistent thickness and parallel to the body of the workpiece. If a cheek is twisted or angled relative to the faces of the workpiece, the result can be a twisted assembly. The same goes for an end rabbet joint.

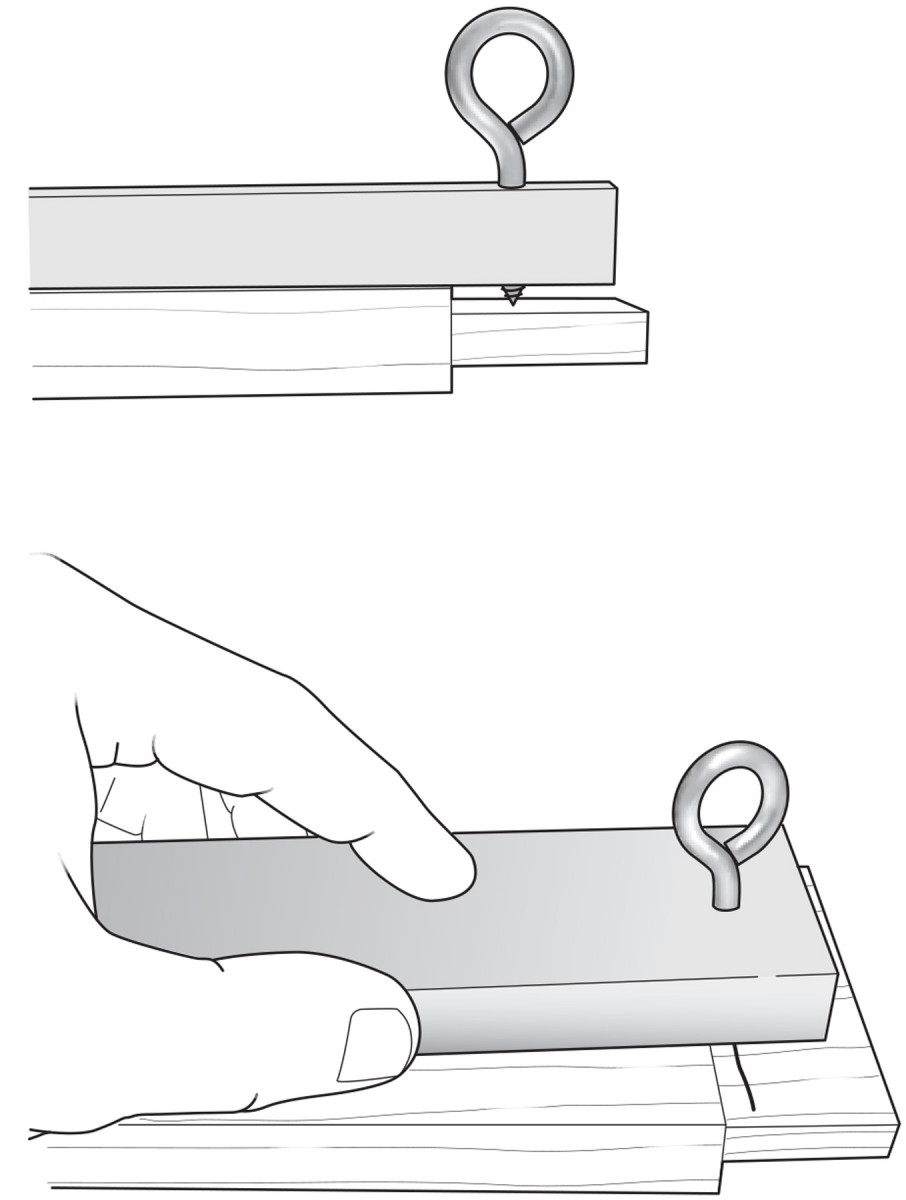

This simple tool can quickly check joint cheeks for twist or angles. It’s nothing more than a straight piece of wood outfitted with a projecting screw eye. It works as sort of a combination depth gauge/scratch awl, with the point of the screw eye marking any high spots that need trimming.

To make the jig, use flat, stable, accurately thicknessed stock of about 3⁄4” x 2″ x 9″. Drill a snug pilot hole about 3⁄4” in from one end and install a sturdy screw eye with a sharp tip. (A standard screw will work, but it won’t adjust as quickly.)

To use the jig, rest it on the workpiece face, adjust the screw so the point barely touches the joint’s cheek surface, then slide the point along the surface. The tip of the screw will scratch any high spots that need paring. Pare and recheck as needed until the point consistently skims the cheek at the desired depth. This technique can be used to fine-tune hand-cut tenons as well as to validate the results of machine setups. — Rob Porcaro

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.