We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

For those of us who don’t own a lathe, or who sometimes need a quick turning solution for small objects without the fuss of a full lathe setup, there is a way to use a drill press as a makeshift lathe.

For those of us who don’t own a lathe, or who sometimes need a quick turning solution for small objects without the fuss of a full lathe setup, there is a way to use a drill press as a makeshift lathe.

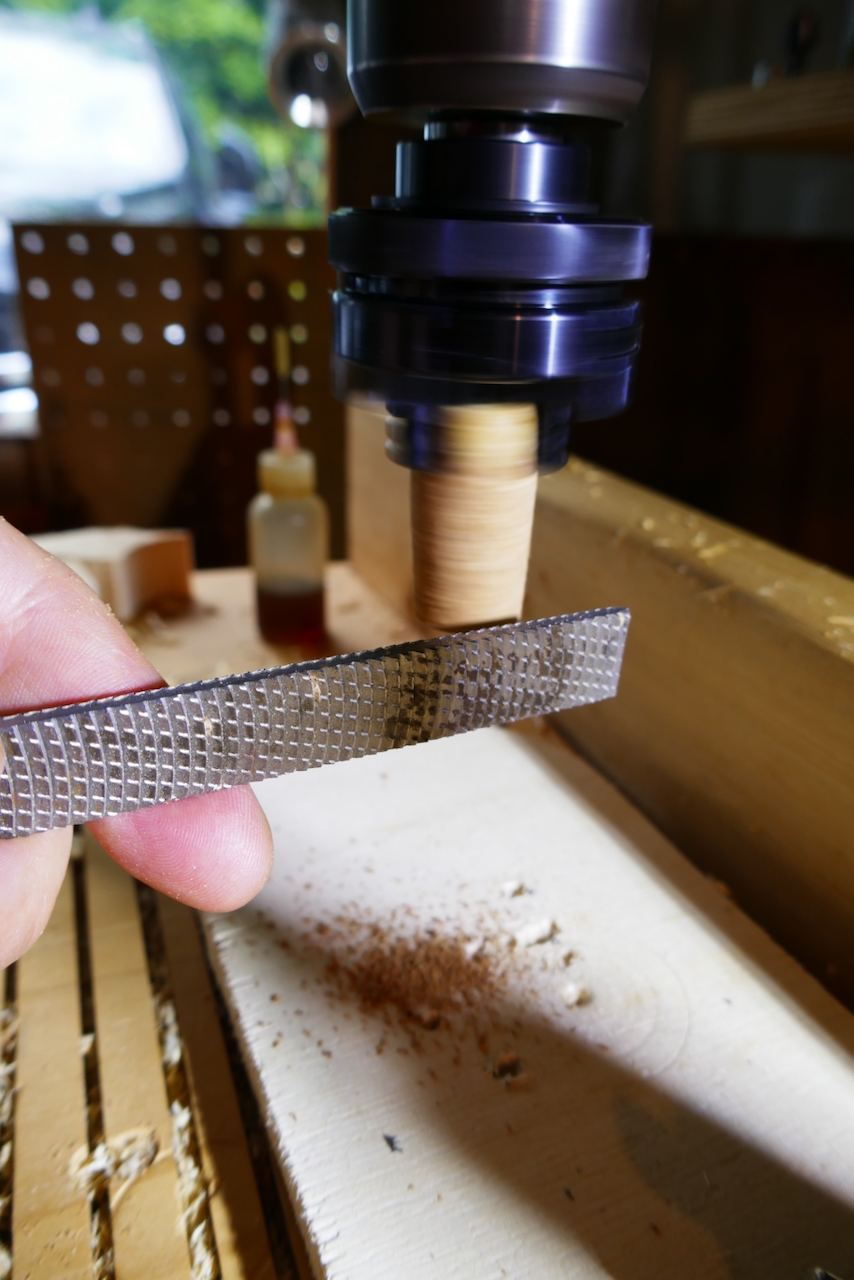

Most of us already use the drill press to gently shape smaller diameter objects, provided they can fit in the machine’s primary chuck. This usually limits us to objects with a maximum diameter of about half an inch, or 5/8″ at the very most. When using the drill press this way—and I’m not talking about using aggressive lathe gouges, but rather using a rasp to round over a knob, or files and sandpaper to smooth hardware pieces or reduce the diameter of a dowel—our options are limited by that chuck capacity.

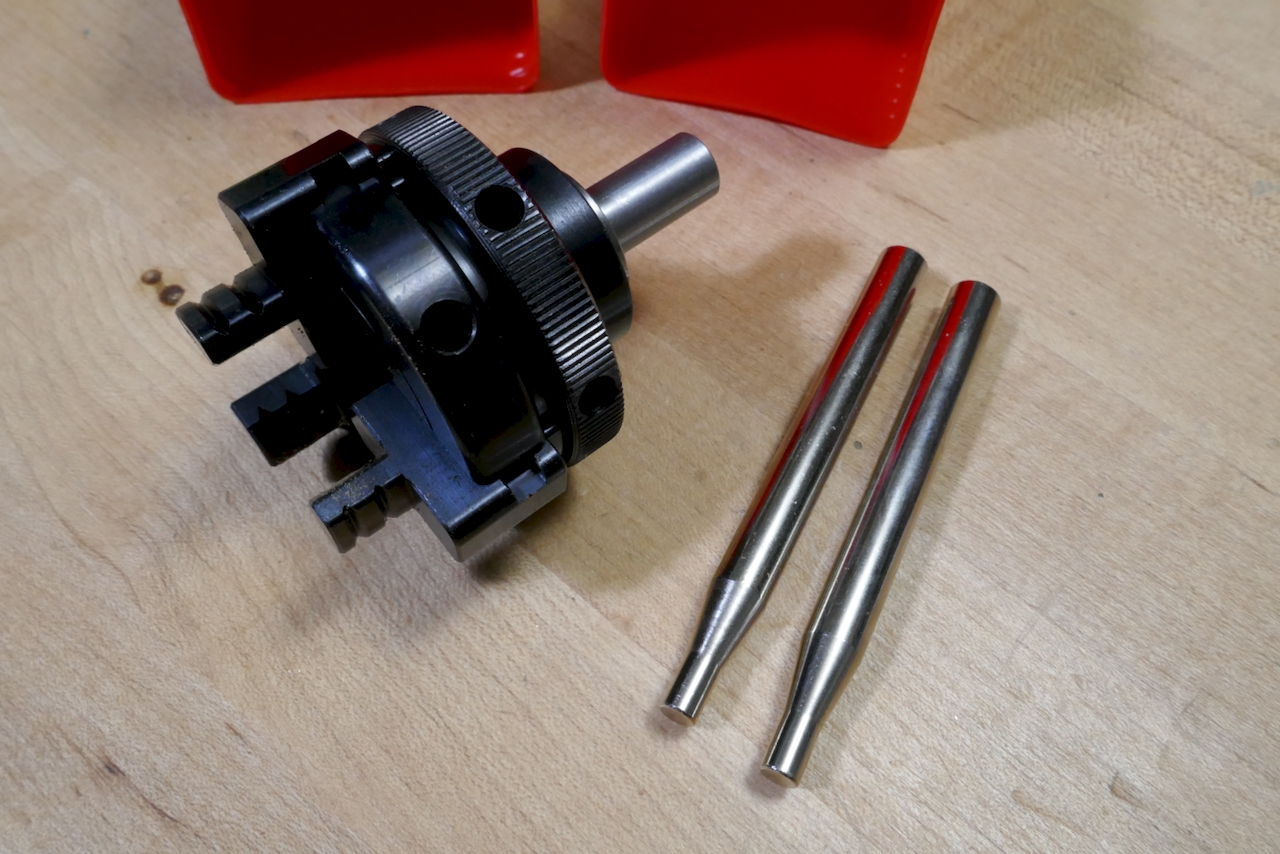

Now, there is a “new kid in town” that allows you to clamp significantly wider diameter workpieces. I’m talking about a miniature lathe chuck that mounts directly into the main chuck of your drill press.

The jaws of this auxiliary chuck can be opened using two rod-style chuck keys to a significant diameter. You then use these rods in a reverse manner to securely tighten the chuck over your workpiece.

When my son lost his water bottle plug, I decided to make a makeshift one for him using a repurposed wine bottle cork. The chuck proved to be just the right tool for the job, allowing me to turn it to the correct size.

A Critical Warning

When operating with this setup, two safety precautions are essential:

- Lateral Pressure on the Workpiece: You must be careful not to apply too much sideways (radial) pressure on your workpiece. Since you are lacking a tailstock center (the support that holds the far end of the workpiece on a proper lathe), the object can easily wobble or be thrown out of alignment.

- Protecting Your Drill Press: You also need to avoid applying excessive lateral pressure on the bearings of your drill press. These bearings are designed primarily to handle vertical force (axial load) for drilling, not the heavy radial load (side pressure) created by shaping or turning a workpiece. Keep your tool pressure light to protect your machine’s longevity.

This is a great, affordable option ($39) for turning small-scale parts when used with caution and respect for the limitations of the drill press.