We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Although routers were originally designed to create moulded shapes, they can be excellent joinery tools. In fact, they’re better in some ways than table saws, professional quality mortisers or dado cutters when it comes to cutting joints. There are several reasons routers have an advantage:

Although routers were originally designed to create moulded shapes, they can be excellent joinery tools. In fact, they’re better in some ways than table saws, professional quality mortisers or dado cutters when it comes to cutting joints. There are several reasons routers have an advantage:

• Simplicity: Setting up hand-held or table-mounted routers is rather straightforward. Tools dedicated to joint-making such as hollow-chisel mortisers are more complex and require more time to set up. Sure, it could be worth the effort to use a mortiser if you’re planning to make dozens of duplicate joints. But if all you want to cut are a few mortises and tenons, for example, a router will save you loads of time.

• Versatility: You can make a greater variety of joints with a router than with any other joinery tool. No matter if you have a fixed-base or plunge router, you can cut more types of joints than with any other kind of tool.

• Accuracy: There isn’t a more precise joinery tool. You may find tools just as accurate, but none that surpass the router. Because routers cut quickly, they leave a smooth surface, meaning joints fit better and bonds are stronger.

There are some disadvantages to using your router for joint-making, and I’d be remiss if I didn’t mention them:

• Most routers won’t stand up to continual cutting as well as heavy-duty woodworking machinery.

• Because you can’t make deep cuts in a single pass on a router, it may take you longer to rout some joints than it would to use a mortiser or dado cutter.

• Depending on the joint you want to make, you may be limited by the sizes and configurations of available bits.

These shortcomings, however, are minor. Routers are indispensable joinery tools in any workshop.

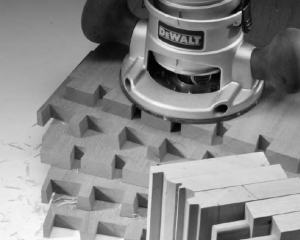

Finger-joint Jig

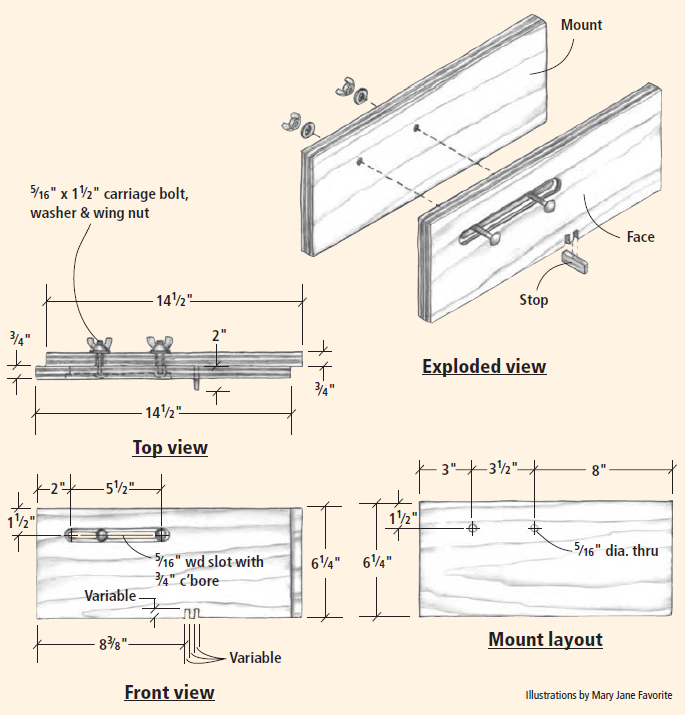

This jig will evenly space notches as you cut them, allowing you to make perfect finger joints. It’s designed to mount on any miter gauge and will work great on your router table (or, if you’re so inclined, you also can use it on your table saw).

Make the face and the mount from cabinet-grade plywood and the stop from hardwood. If you wish, you can make several different faces, each with a different-sized stop. This will enable you to cut different sizes of finger joints.

To use the jig, screw or bolt the mount to a miter gauge. Loosen the wing nuts that secure the face to the mount and slide the face sideways until the stop is the proper distance away from the bit. When the stop is positioned properly, tighten the wing nuts.

The above post is an excerpt from our new “Woodworker’s Router Collection,” in which you’ll find this and other terrific articles by Nick Engler – not to mention full-length DVD instruction and one of Glen Huey’s favorite router bits! Buy your value pack today for only $79.99, exclusively in our store.

The above post is an excerpt from our new “Woodworker’s Router Collection,” in which you’ll find this and other terrific articles by Nick Engler – not to mention full-length DVD instruction and one of Glen Huey’s favorite router bits! Buy your value pack today for only $79.99, exclusively in our store.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I would also disagree with this article. I don’t know what’s gotten into the water supply, but making mortises with a router is actually much more time consuming than just grabbing a mortise chisel and doing it by hand. To make a mortise with a router, you have to make a jig to control the machine. The time spent making the jig could be spent actually doing the work and it would avoid wasting material on a jig that might only be used for one project.

If I had a hollow chisel mortiser, setting that tool up would also take less time than creating a jig for the router. It seems like everyone assumes that making the jig is free in time and resources when it really isn’t…

I could not agree more Joe. I would add that they are painfully noisy and extremely dangerous in untrained hands. They are also expensive, not so much in themselves but the cost of cutters, jigs, tables and essential dust extraction and filtration soon add up to a lot of money for very little return.

Manufacturers drive the sales of such tools not the needs of the amateur and small artisan woodworker. John Brown , the renown Welsh chair maker, was of the opinion that the amateur did not “need” any electrical machines. I agree. We are being seduced into thinking we need them by their manufacturers and those who rely on the advertisments they place.

They certainly make doing things quicker and easier, including making an utter mess of what you’re working on.

I tend to do things by hand as the longer time taken is largely offset by the time needed to set-up and put away my router, to say nothing of cleaning up the dust it’s thrown all over the place.

I’m sure that for repetitive tasks they must be a huge asset though.