We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Is Your Shop Too Small?

Tips for

making

king-size

projects in

a pint-size

shop.

By George Vondriska

n a recent poll of woodworkers, the

most common complaint,by far, was that

their shops were too small. Even one guy

with 5,000 square feet thought he was

cramped!

In spite of that, most of us would like to

be able to turn out dining room tables,

kitchen cabinets and other big projects.

Well, if your shop and tools are small,

but your dreams are gigantic, here are

some ideas that will help.

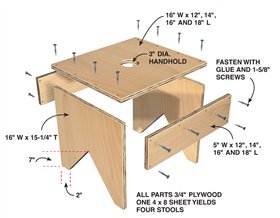

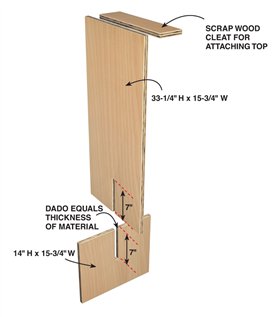

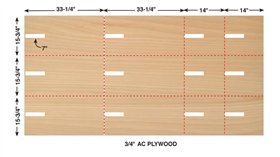

A nest of crickets

Call them low boys, stools or crickets—

whatever you call them, these

stands are amazingly useful. And

because they nest, they’re perfect for a

cramped shop. You can make four of

them out of one sheet of 3⁄4-in. plywood.

The 16-in. height is just right for

large work that might not fit on normal

sawhorses. For working around the

house, that extra height makes it easy to

reach the ceiling. If that’s not reason

enough, when your buddies come over

to give you “helpful” shop advice,

you’ve got plenty of seating.

|

|

Click any image to view a larger version.

|

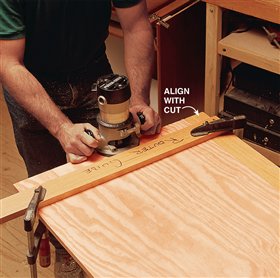

Use a router for crosscuts

Ever tried to trim the ends on an

8-ft. dining table in a shop that’s

only 9-ft. wide? The trick is to

use a router instead of your tablesaw.

Rough-cut the top with a circular

saw or jig saw first, using a

fine blade to avoid splintering.

Then use a simple T-square jig

and a router with a straight bit to

trim the work to length.

Note that one leg of the

T-square has already been

trimmed by the router, so you

can simply line up that end with

your cutting line. Hang on to the

jig and use it only with that router

and bit. I once made a bunch of

cabinets without using a tablesaw

at all. I simply rough-cut the

pieces with a circular saw (see p.

50), then trimmed them to final

size with a router.

|

|

|

Cut dadoes with a router

Here’s the scene: You’re building an

entertainment center and the sides are

7-ft. high and almost 3-ft. deep (big

enough for that big-screen TV you’ve

always wanted). But the sides have to

be dadoed for shelves. Forget trying

to use a dado head on

the tablesaw, unless you happen

to have 8-ft. rails on your saw!

Instead, use a router and this easily

made jig:

Make the jig from a straight board

and a piece of 1⁄8- or 1⁄4-in. plywood or

hardboard wide enough to extend 4

in. on either side of the board. Glue and

screw together, then trim the bottom board using

your router and a

straight bit. The diameter of

the bit should be whatever size you

plan to use for the dado. I trim one side with a

1⁄2-in. bit and the other side with a 3⁄4-in. bit.

To cut the dado, simply line up the edge of the

jig with wherever you want the dado.

|

|

Making the jig

|

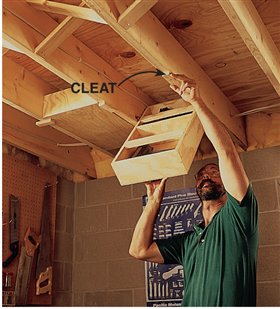

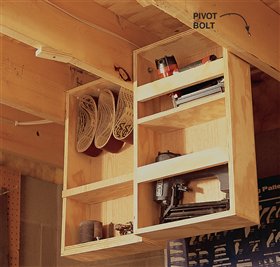

Ceiling drawers

To eke out every cubic inch of

storage in a basement shop, try

these boxes that hang between

your ceiling joists. When a

drawer is down, you have easy

access to its contents. A lag screw

or bolt works well for a pivot

and a pair of pivoting cleats holds

each drawer in place. They’re

perfect for tools and supplies you

don’t need to get at all the time.

|

|

|

Collapsible work stands

In a small shop, the more things that can be folded

up and moved out of the way, the better. These

work stands are easy to build, easy to store and

cheap. They’re especially good for finishing and

gluing up panels. One sheet of 5⁄8-in. AC plywood

will yield six stands. If you make them the same

height as your tablesaw they will double as infeed

and outfeed supports.

|

|

|

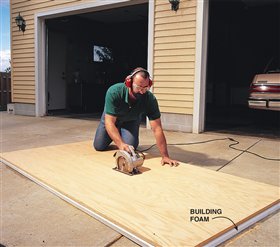

Rough-cut plywood

It’s awkward to manhandle plywood in a small

shop and sometimes your cuts aren’t accurate

just because the sheets are so unwieldy. One solution

is to rough-cut the pieces with a circular

saw and then make final cuts on your tablesaw.

Lay the plywood on top of a piece of building

foam, use a fine-tooth blade in your saw and set

the saw so it cuts just 1⁄8-in. deeper than the plywood.

Then simply kneel on top to cut. It’s much

easier than sawhorses.

Make sure that you leave a factory edge on

each piece that you cut. Although you may have

to trim it off later, it’s essential as a reference for

your first cut on the tablesaw.

|

|

|

Pay for service

For some situations, the easiest

thing to do is to pay a

larger shop to do the work.

For example, a wide belt

sander, shown at left, is great

for leveling glued-up tabletops,

especially if the grain is

curly or otherwise difficult to

plane. You’ll find one in cabinet

shops and even some large

school shops. Cost to have

this done is variable, but generally

low.

|

|

|

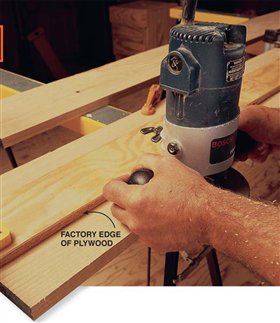

Joint edges with a router

Trying to joint the edges of 8-ft. long by 12⁄3-

in.-thick hard-maple boards on a small jointer

can end in disaster. Use a router, guided

by a long straightedge, instead. The factory

edge on a piece of hardwood plywood is

sufficiently straight. Clamp the straightedge

to the board so you’re removing about 1⁄16 in.

Use a straight 1⁄2-in. or 3⁄4-in. bit with a guide

bearing above the bit (available from mailorder

sources like Jesada Tools, 800-531-

5559; around $30).

|

|

|

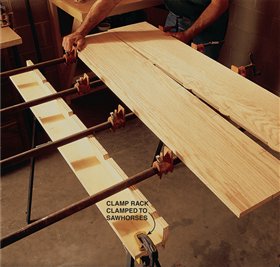

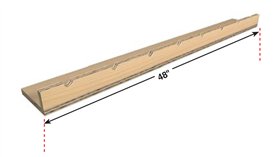

Easy-to-store clamp racks

In a small shop, there’s no room

for a dedicated glue-up table,

and often no room for much of

an assembly table either. But you

can make room for edge gluing

with these clamp racks that fasten

to sawhorses when needed.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.