We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Turning Plates

Got an offcut from a beautifully

figured board? Turn it into

a plate! Standard 3⁄4-in. wood

and a shop-made chuck are

all you need.

By Steve Blenk

|

The trick is to figure out how to hold such

a thin piece of wood on the lathe. It’s so thin,

there’s hardly anything to grab onto. Here’s a

safe and simple system for turning a plate

from thin wood.

All you’ll need is a small face plate, a

medium-sized bowl gouge (3⁄8-in. to

1⁄2-in.), a round-nose scraper, some masking

tape and a large, thick chunk of wood for the

chuck.

A plate blank that’s 9- to 10-in. wide works

best. It can be glued-up or cut from a wide

board, just as long as one side is flat and

smooth. You’ll need that flat surface in order to

glue the plate blank onto a mounting block.

To make the blank, cut off a square piece

from the wide board and cut it into a rough circle

with a bandsaw. Draw a 3-in. circle in the

center of the blank’s smooth side. Then make

a 3-in.-dia. mounting block from a piece of

1-in.-thick wood that’s been surfaced on both

sides. Screw the mounting block onto a small

face plate. Now follow the photo sequence

and create your own stunning plate.

|

|

Click any image to view a larger version.

|

|

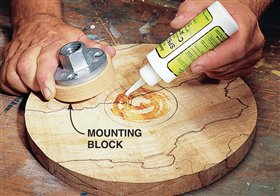

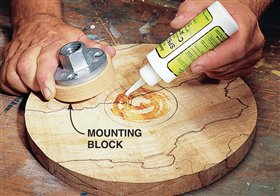

1. Glue the mounting block onto

the plate blank. Use medium- to thickviscosity

cyanoacrylate (CA) glue. It

dries quickly, so you’ll be ready to turn

in two to three minutes.

Adjust your lathe to run at its lowest

speed.Then mount the face plate on

the lathe and true up the face and

edge of the blank with a bowl gouge.

|

|

|

|

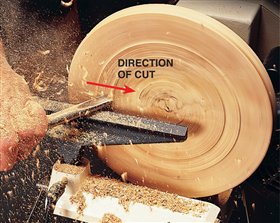

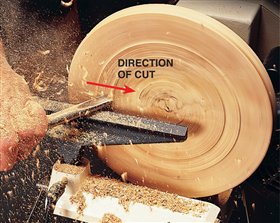

2. Round the plate’s rim with

the bowl gouge turned on its side.

This prevents the gouge from

catching and is called a “closed

cut.” Move in the direction of the

arrow and swing the handle of the

gouge around the corner. Ride the

bevel of the gouge on the plate,

keeping the cut very light.

|

|

|

|

3. Flatten the face of the plate.Work

from the outside to the center. Keep the

bevel of the gouge rubbing against the

plate to make this shearing cut.

Because you are working with thin

material, use light shearing cuts, especially

around the rim.You can place your hand

behind the rim to reduce vibration.

|

|

|

|

4. Cut a cove to define the rim.

Drop the handle of the gouge below

the level of the tool rest so the gouge

won’t catch. Keep the bevel riding on

the plate.

Next dish out the center of the plate

with shearing cuts. Measure the depth

of the plate before you cut too deep.

If you’re careful you should be able

to make a very smooth surface across

the entire face of the plate with the

gouge.You can move right on to

sanding. But if you’ve had some

trouble and there are tool marks you

can’t get out, reach for a scraper.

|

|

|

|

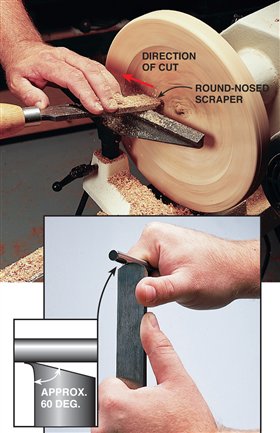

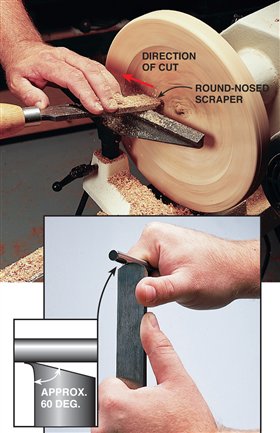

5. Scrape the face of the

plate with light cuts for a

smooth surface.Move

from the center out to the

edge. Raise the handle of

a round-nose scraper

above the level of the tool

rest so its cutting edge

won’t grab.

Burnish a scraper’s

edge at a 90-degree

angle. Grind the scraper

first at 60 degrees, then

remove the wire edge

with a sharpening stone.

Burnish with a single pass,

using hard pressure (see

Sources, below.

|

|

|

|

6. Remove most of the waste from the back side of the plate. Move the bowl

gouge from the center out to the edge.Take the rim down to its final thickness.

Again, you can support the rim with your hand to reduce vibration.

Sand the face of the plate and apply a finish as it spins on the lathe. Sand and finish

the outer edge of the back side as well.Then remove the face plate from the lathe.

|

|

|

|

7. Make a rim chuck to hold the face side of the plate.Make the chuck from a wide

piece of hardwood.The wood should be at least 11⁄2-in. thick or make the chuck from two

3⁄4-in.-thick pieces of marine plywood that are glued together. (Marine plywood is free of

annoying voids.)

Turn a recess into the face of the chuck.The plate should fit snugly within it, but you can

insert paper shims if it’s a little loose. (You can re-use the chuck for smaller plates by

turning another recess.) Drill a hole through the chuck so you can pop out the plate with

finger pressure.

Once the plate is mounted, snug up the tailstock to the mounting block to hold the

plate securely in the chuck.

|

|

|

|

8. Reduce the mounting block to a

1⁄2-in.-dia. stub tenon with the bowl

gouge.Then shape the plate’s base and

complete the underside of the rim. Sand

and finish the back while it’s still

supported by the tailstock.

|

|

|

|

9. Tape the plate into the rim

chuck. Use plenty of wide

masking tape. Adjust the lathe

to run at its lowest speed.Then

back off the tailstock and cut

off the stub tenon with the

bowl gouge.

Use light cuts so you don’t

dislodge the plate. Sand and

apply finish to the rest of the

plate’s bottom. Remove the

tape as soon as possible so it

doesn’t leave any marks.

|

|

|

Commercial Rim Chucks

If making a wooden rim chuck for every plate you turn seems like too

much work, try a commercial adjustable rim chuck. A turn of the wrench

simultaneously moves four aluminum jaws in and out to firmly anchor your

plate. Eight rubber buttons screwed into tapped holes in the jaws hold the

edge of the plate.

Pictured at the right is a set of Jumbo Jaws mounted on a Oneway Stronghold

Chuck. They can hold a plate from 23⁄4- to 11-in. diameter.

|

|

|

Fig. A: Cross Section of Typical Plates

Try these classic

shapes for starters or

copy any piece of china

that you like.The

thickness of your wood

plate shouldn’t be less

than 3⁄16 in.

|

|

|

Sources

(Note: Product availability and costs are subject to change since original publication date.)

Packard Woodworks, 800-683-8876, Plate Finish.

If your plate will have food served on it,

use Behlen’s Salad Bowl Finish. It’s a quick drying

food-safe varnish,125701, 1 pint.

Hock Handmade Knives, 888-282-5233, Unhandled 3⁄8-in. Burnisher, #BR375.

Lee Valley Tools, 800-871-8158, Veritas Scraper Burnisher

#05K35.01.

This story originally appeared in American Woodworker February 2000, issue #78.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.