We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Flammables cabinet safely stores solvent-based supplies. Designed to shield flammable solvents and finishing materials long enough for you to escape a fire.

This 3-cabinet unit is designed to organize and store finishing supplies ranging from flammable liquids to Q-tips in ways that makes them easy to access and (just as important!) easy to put back. To avoid clutter, it’s designed to limit whatever is being stored to one layer deep.

Full-extension drawers Movable dividers allow customized storage of finishing supplies and personal protection gear.

Safely storing flammable liquids (a requirement in professional settings) is a good idea for any home shop. In this unit, the bottom cabinet is constructed to meet the code requirements of the National Fire Protection Association for a wooden flammables storage cabinet. It’s built with 1″ AC exterior fir plywood, using shouldered joinery that’s glued and screwed, applied door seals, spring hinges and cupboard latches, flame retardant paint and special signage.

Pullout tray Provides a clean work surface for pouring and mixing materials. Contains spills, too.

After reading about its heavy-duty construction, you may be surprised to learn that a flammables cabinet is not meant to contain a fire. Its real purpose is to keep fire away from flammable liquids as long as possible, for both your benefit and for firefighters. This cabinet is designed to keep flames away from your flammables for 10 minutes, so you have time to escape a fire. Keeping all your finishing supplies in one highly visible spot allows firefighters to quickly isolate a danger zone.

Magnetic tool holder A steel panel and rare earth magnets create a versatile holder for brushes and other finishing tools.

The middle cabinet has drawers with over-travel slides to allow full access. The bottom drawer is deep enough to store clean rags, tack cloths, gloves, dust masks, and even a respirator. The center drawer is just right for sandpaper sheets, sanding blocks, steel wool and other abrasives. Both drawers feature movable dividers.

Task lighting A box on the top holds lights and provides additional storage.

The top drawer is actually a shallow tray for preparing and mixing stains and finishes. When the tray is fully open, installing a simple stabilizer virtually eliminates the side-to-side movement caused by the drawer slide mechanisms.

Easy mobility Heavy-duty swivel casters lock and roll this cabinet.

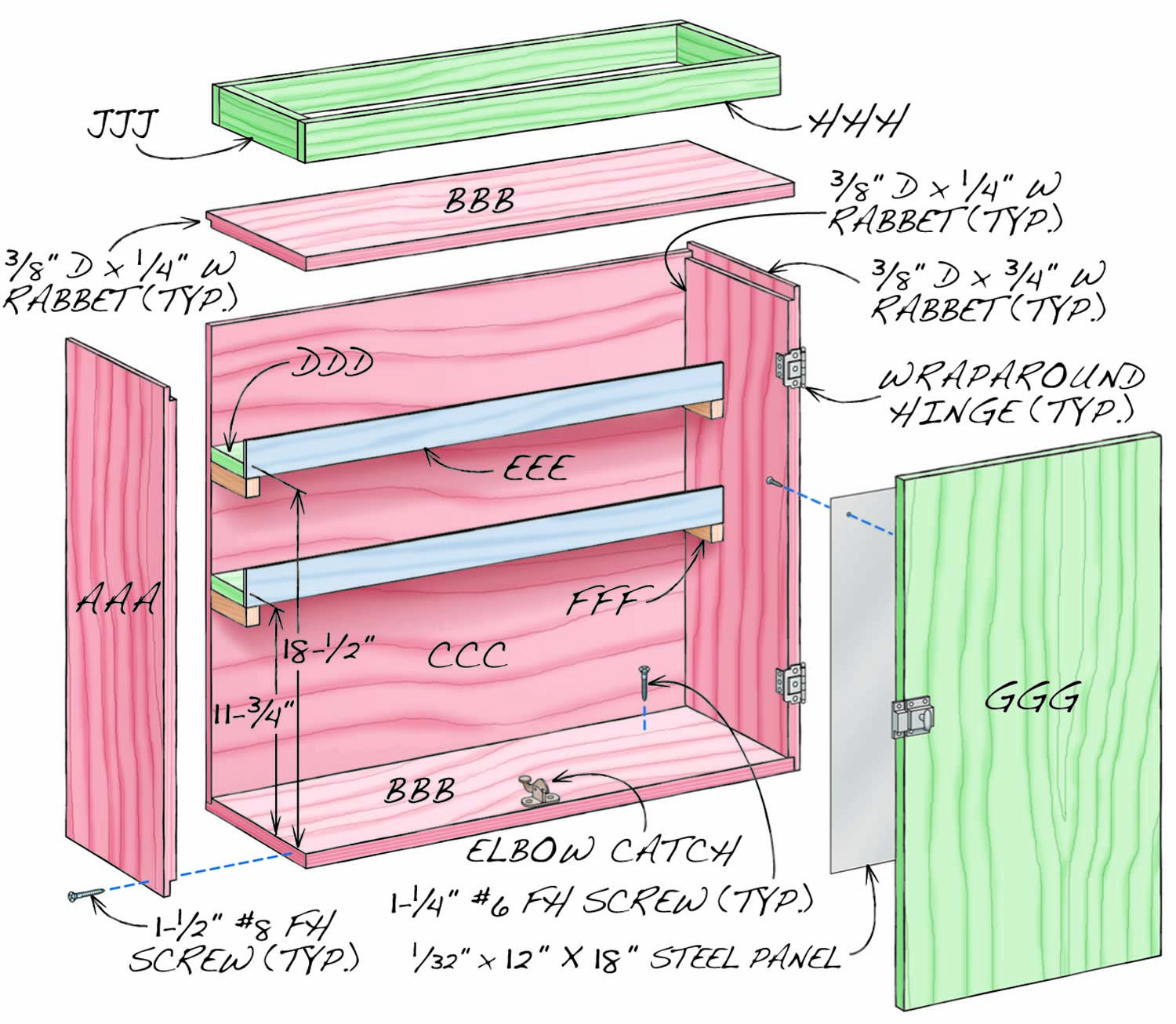

The upper cabinet has shallow shelves for storing small containers of glue, dye, putty, touch-up materials, measuring cups and such. Long screws installed on both sides allow hanging tape and lightweight tools such as a spray gun.

The left door stores tools the old-school way, on screws. The door on the right employs a steel panel and rare earth magnets—a versatile storage system that can easily be easily and completely rearranged.

The doors mount on free swinging hinges, so they don’t snap shut. Instead, an old-fashioned elbow catch and cupboard latch keep them closed. Instead of a fancy cornice, the top of the cabinet has a box that I use to store clean, empty containers. It also works well as a clamp light holder.

To build this cabinet, you’ll need one sheet of 1″ exterior fir plywood, two sheets of 3/4″ exterior fir plywood, one sheet of 1/4″ plywood and a half sheet of 1/4″ hardboard.

To build the all three cabinets, you’ll need one 4×8 sheet of 1″ AC exterior fir plywood, two 4×8 sheets of 3/4″ AC exterior fir plywood, one 4×8 sheet of 1/4″ exterior fir plywood and a 2×4 piece of 1/4″ tempered hardboard. You can custom-order 1″ AC exterior fir plywood at most home centers. Full-service lumberyards typically keep it in stock.

When building this project, keep in mind that plywood thicknesses are almost always undersize. Because this thickness can vary, the dimensions in the cutting lists are based on full thicknesses—1″ plywood is considered to be 1″ thick, for example. Make adjustments, as necessary, according to your plywood’s thickness.

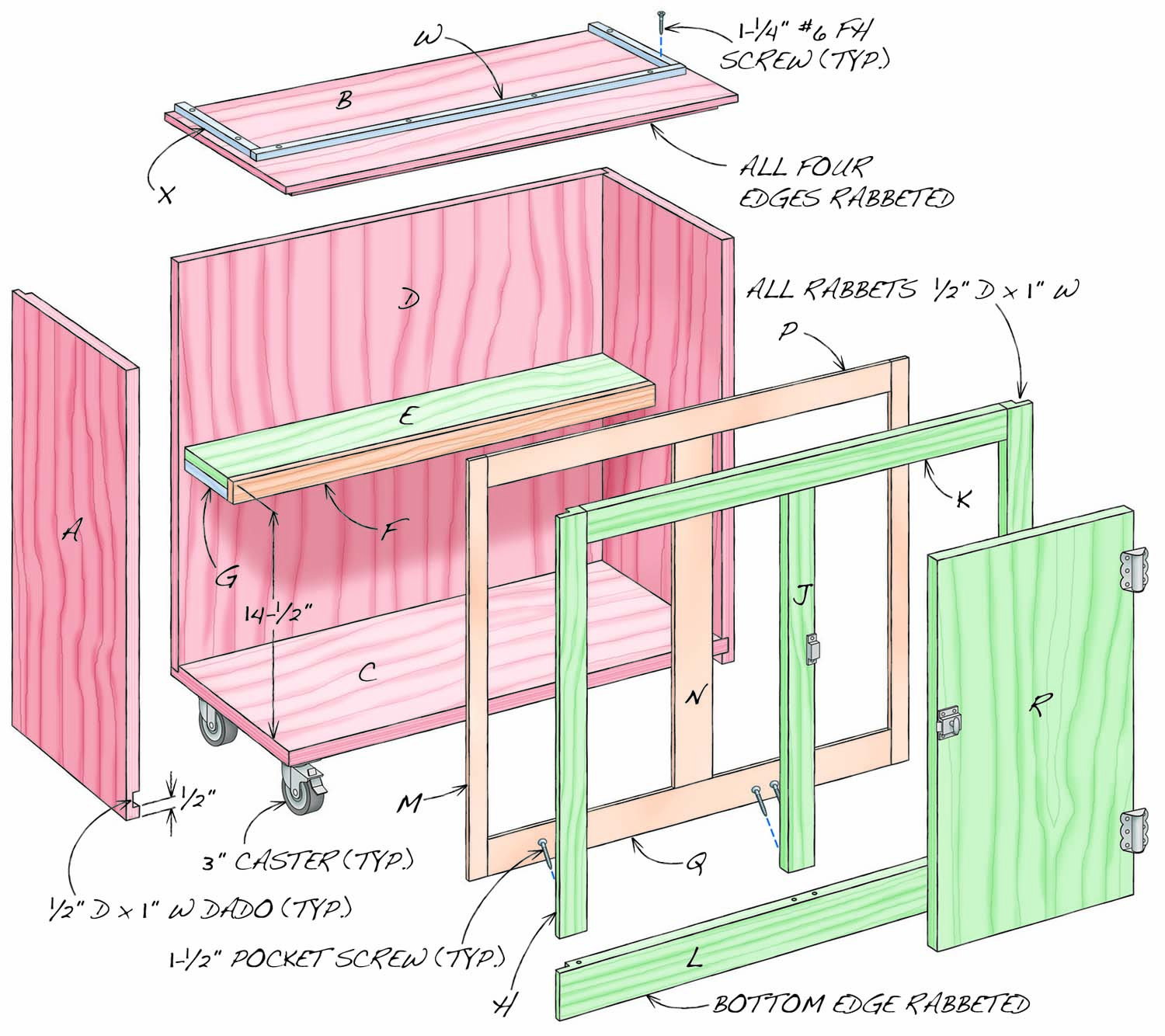

Fig A. Exploded View: Flammables Cabinet This cabinet has been designed to meet the National Fire Protection Association’s requirements for a wooden flammable liquids storage cabinet established in Section 9.5 of the 2012 edition of NFPA 30, Flammable and Combustible Liquids Code. For more information visit nfpa.org.

Fig B. Flammables Cabinet Joint Details

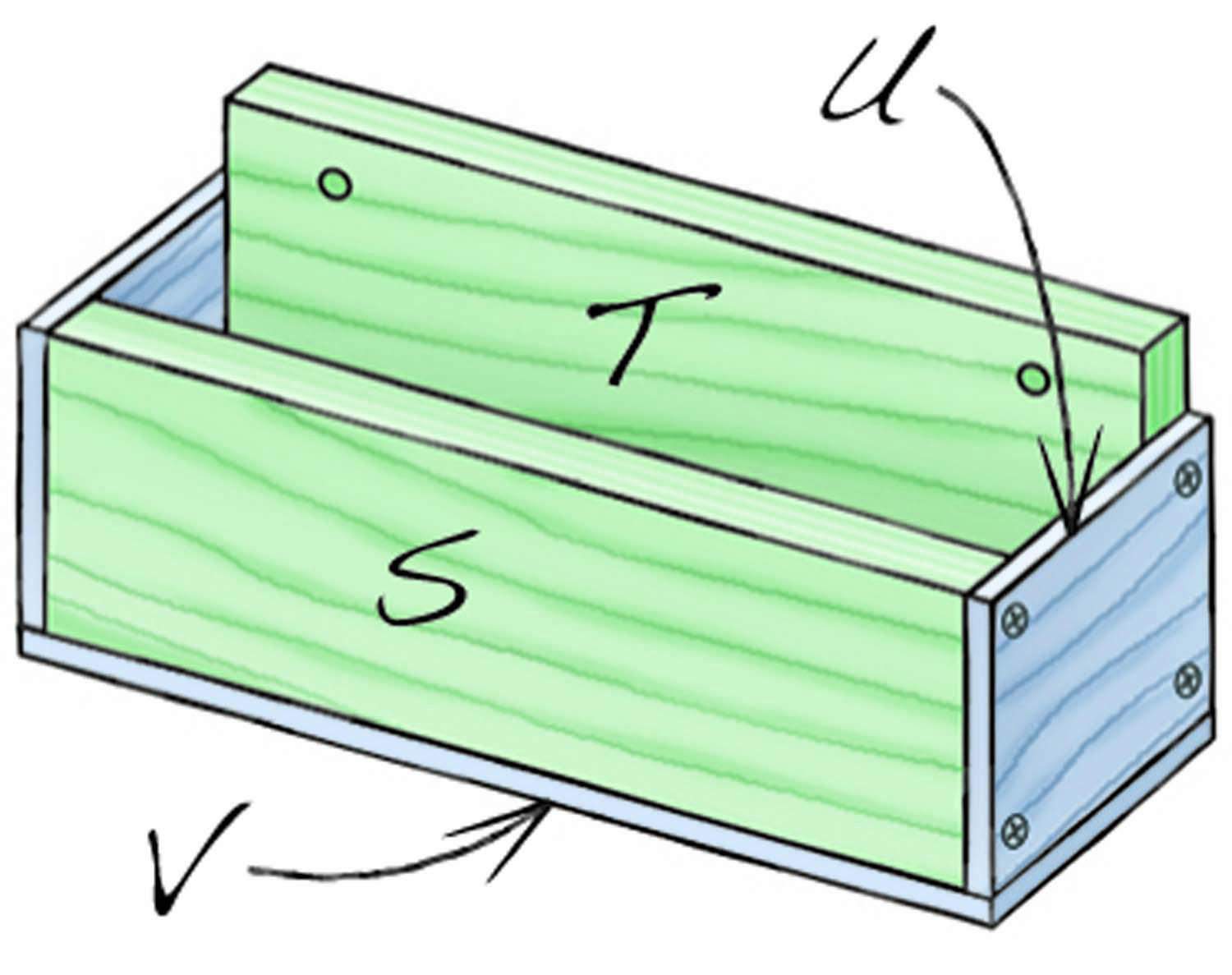

Fig C. Flammables Cabinet Door Box

| Finishing Cabinet—Flammables Cabinet Overall Dimensions: 33-1/2″ H x 36″ W x 16-1/2″ D (a) |

||||

| Part | Name | Qty. | Material | Th x W x L (b) |

| A | Side | 2 | Exterior fir plywood | 1″ x 16″ x 29″ |

| B | Top | 1 | Exterior fir plywood | 1″ x 16″ x 36″ |

| C | Bottom | 1 | Exterior fir plywood | 1″ x 16″ x 35″ |

| D | Back | 1 | Exterior fir plywood | 1″ x 28 x XX” |

| E | Shelf | 1 | Exterior fir plywood | 3/4″ x 6″ x 34 3/4″ |

| F | Lip | 1 | Pine | 3/4″ x 1-1/2″ x 34-3/4″ |

| G | Cleat | 2 | Exterior fir plywood | 1/2″ x 3/4″ x 5-7/8″ |

| H | Face frame stile | 2 | Exterior fir plywood | 1″ x 2″ x 25-1/2″ |

| J | Face frame middle stile | 1 | Exterior fir plywood | 1″ x 2″ x 23-9/16″ |

| K | Face frame top rail | 1 | Exterior fir plywood | 1″ x 2″ x 32″ |

| L | Face frame bottom rail | 1 | Exterior fir plywood | 1″ x 3″ x 36″ |

| M | Door seal stile | 2 | Hardboard | 1/4″ x 1-1/2″ x 27″ |

| N | Door seal middle stile | 1 | Hardboard | 1/4″ x 3″ x 22-1/2″ |

| P | Door seal top rail | 1 | Hardboard | 1/4″ x 2″ x 30-3/4″ |

| Q | Door seal bottom rail | 1 | Hardboard | 1/4″ x 2-1/2″ x 30-3/4″ |

| R | Door | 2 | Exterior fir plywood | 1″ x 14-3/4″ x 23-5/16″ |

| S | Door box front | 4 | Exterior fir plywood | 3/4″ x 3″ x 10-3/4″ |

| T | Door box back | 4 | Exterior fir plywood | 3/4″ x 4″ x 10-3/4″ |

| U | Door box side | 8 | Exterior fir plywood | 1/4″ x 3″ x 4-1/4″ |

| V | Door box bottom | 4 | Exterior fir plywood | 1/4″ x 4-1/4″ x 11-1/4″ |

| W | Front retainer | 1 | Exterior fir plywood | 3/8″ x 3/4 x 34-1/4″ |

| X | Side retainer | 2 | Exterior fir plywood | 3/8″ x 3/4 x 14-1/2″ |

| Notes (a) Overall height includes casters and retainers. (b) Plywood thickness is nominal. |

||||

Flammables cabinet

Cut the cabinet’s 1″ plywood sides, top, bottom and back (A–D, Fig. A and Cutting List, page xx) to final dimensions. Next, cut a 1/2″ deep x 1″ wide dado in each side piece for the bottom. Cut 1/2″ deep x 1″ wide rabbets in the back edges of the side pieces and bottom and on all four edges of the top. Then assemble the box, using glue screws spaced about 6 ” apart (Photo 1). Then, after predrilling countersunk pilot holes, screw all the rabbet joints from both sides (Fig B),.

Photo 1. Assemble the base cabinet with glue and screws. The parts are made of 1″ exterior grade plywood and all the joints are shouldered, glued and screwed.

Cut the shelf (E) to size and glue on its lip (F). Note that the shelf is made using 3/4″ plywood. Screw the cleats (G) in position inside the cabinet. Then screw the shelf to the cleats, so there’s no chance for it to fall when you move the cabinet around.

Photo 2. Install the door seal parts on the back of the cabinet’s face frame. By overlaying the door openings, the seal minimizes airflow through the gaps around the doors.

Cut the face frame stiles and rails (H–L) from 1″ plywood. Note that the bottom rail is wider than the top rail. Assemble the face frame using glue and 1-1/2″ pocket screws.

Cut the hardboard door seal pieces (M–Q) to size and test-fit them on the back of the face frame to make sure they extend beyond each door opening on all four sides (Photo 2). They must also cover the face-frame’s surface, rest slightly more than 1/2″ below its top and just inside all three rabbets. Fasten each door seal piece with glue and nails.

Turn over the face frame and size the doors (R) to fit with 1/16″ gaps all around. Then fasten the face frame to the cabinet with glue and screws, as before. Attach the casters (locking casters on the front).

Photo 3. Install spring hinges to mount the doors after using shims to center them in the openings.

Apply fire retardant paint (see Sources) and let it dry. Then shim the doors in the openings and install the surface mounted spring hinges (Photo 3; see Sources). Build the door racks (S–V; Fig. C) and attach them to both doors, making sure they don’t interfere with the doors’ automatic closing (Photo 4). Plan to fasten the retainers (W, X) later, after you’ve built the drawer cabinet.

Photo 4. Screw storage racks on the doors to hold aerosol cans and other small containers.

Cabinet boxes

The two cabinets above the flammables cabinet aren’t intended to store flammable liquids, so they’re built using 3/4″ plywood. Although one has drawers and the other has doors, both cabinets are built the same way, so you can assemble them at the same time.

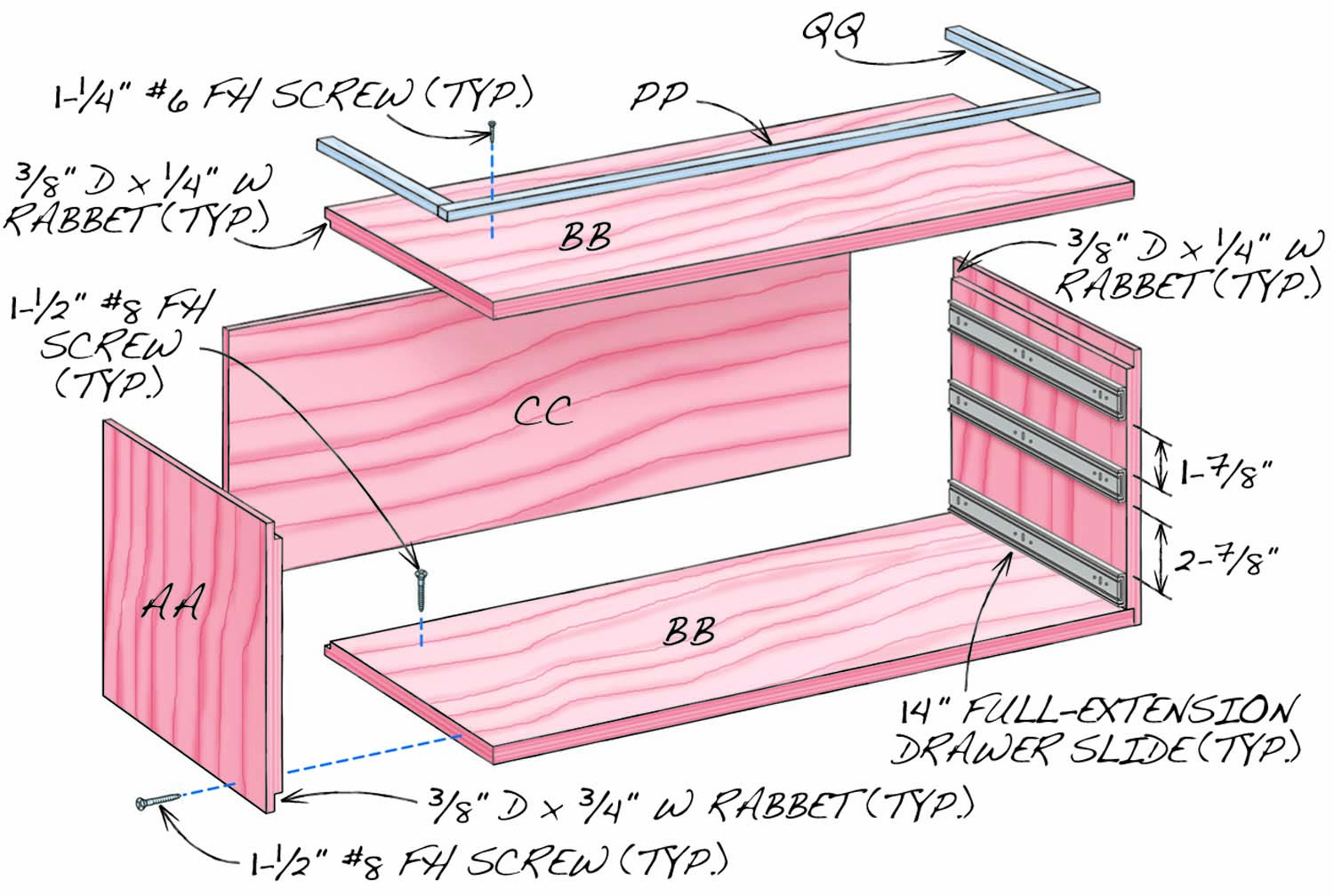

Cut to final dimensions the sides, top and bottom for both cabinets (AA, BB, Fig D; AAA, BBB, Fig E; Cutting Lists, page xx). Cut 3/8″ deep x 3/4″ wide rabbets on both ends of the cabinet sides and a 3/8″ deep x 1/4″ wide rabbet on the back edge of every piece for the cabinets’ backs. Cut the cabinet backs (CC, CCC) to final size. Then assemble each cabinet with glue and screws. As before, predrill countersunk pilot holes. Assemble and install the box on top of the door cabinet (HHH, JJJ) with glue and screws.

Fig. D. Exploded View: Drawer Cabinet

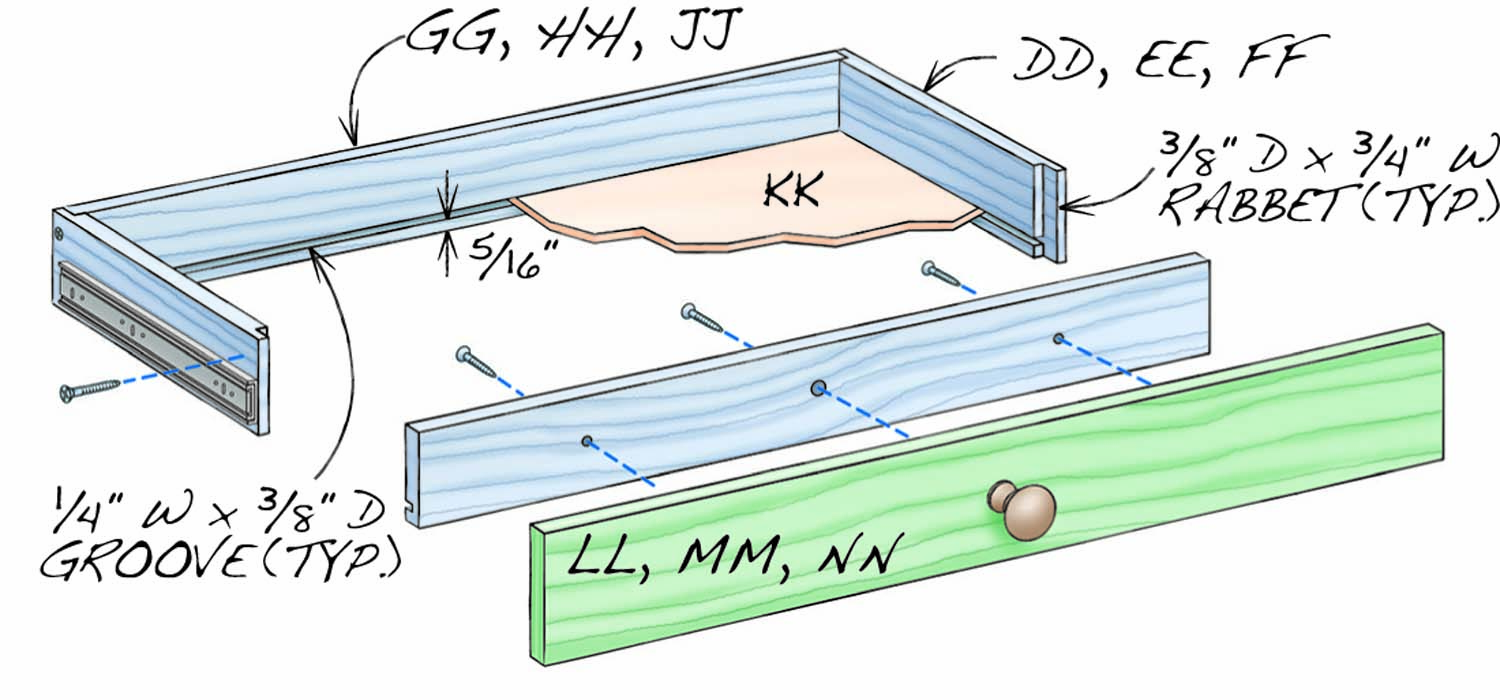

Fig E. Exploded View: Drawer

Fig. F. Drawer Divider

Fig. G .Tray Stabilizer

| Finishing Cabinet-Drawer Cabinet Overall Dimensions: 12-3/8″ H x 32-3/4″ W x 14-1/2″ D (a) |

||||

| Part | Name | Qty. | Materials | Th x W x L (b) |

| AA | Side | 2 | Exterior fir plywood | 3/4″ x 12″ x 14-1/2″ |

| BB | Top/bottom | 2 | Exterior fir plywood | 3/4″ x 14-1/2″ x 32″ |

| CC | Back | 1 | Exterior fir plywood | 1/4″ x 32″ x 11 1/4″ |

| DD | Top drawer box side | 2 | Exterior fir plywood | 3/4″ x 2″ x 14″ |

| EE | Top drawer box front/back | 2 | Exterior fir plywood | 3/4″ x 2″ x 29-1/2″ |

| FF | Mid drawer box side | 2 | Exterior fir plywood | 3/4″ x 3-1/2″ x 14″ |

| GG | Mid drawer box front/back | 2 | Exterior fir plywood | 3/4″ x 3-1/2″ x 29-1/2″ |

| HH | Bottom drawer box side | 2 | Exterior fir plywood | 3/4″ x 4-1/2″ x 14″ |

| JJ | Bottom drawer box front/back | 2 | Exterior fir plywood | 3/4″ x 4-1/2″ x 29-1/2″ |

| KK | Drawer box bottom | 3 | Hardboard | 1/4″ x 13-3/16″ x 29-7/16″ |

| LL | Top drawer front | 1 | Exterior fir plywood | 3/4″ x 3″ x 30-1/4″ |

| MM | Mid drawer front | 1 | Exterior fir plywood | 3/4″ x 3 1/2″ x 30-1/4″ |

| NN | Bottom drawer front | 1 | Exterior fir plywood | 3/4″ x 4 1/2″ x 30-1/4″ |

| PP | Front retainer | 1 | Pine | 3/8″ x 3/4″ x 32-3/4″ |

| Side retainer | 1 | Pine | 3/8″ x 3/4″ x 10-1/2″ | |

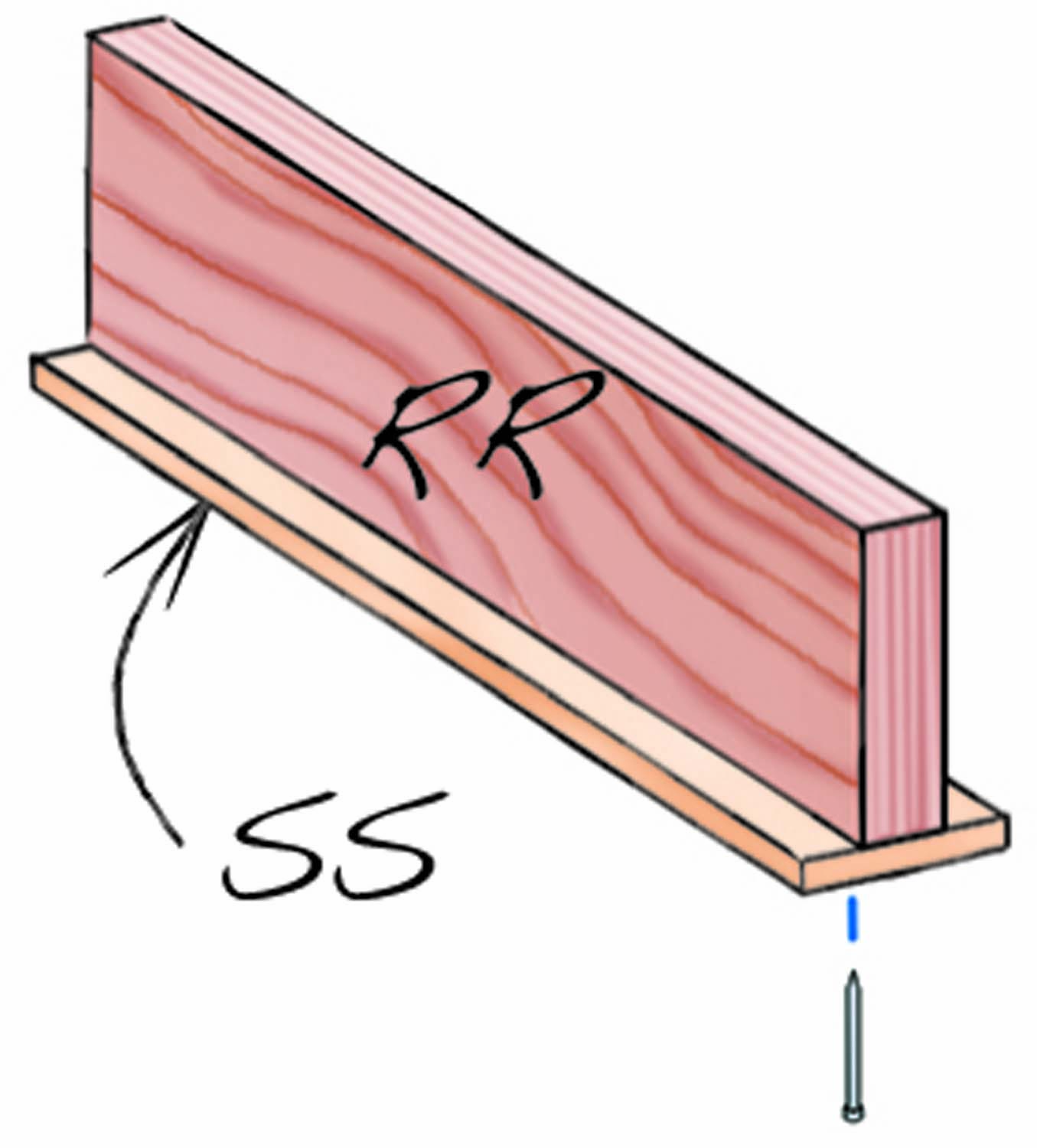

| RR | Stabilizer bar/rail | 2 | Exterior fir plywood | 3/4″ x 1-1/2″ x 28-1/2″ |

| SS | Divider | 4 | Exterior fir plywood | 3/4″ x 2-1/2″–3-1/2″ x 12-1/2″ |

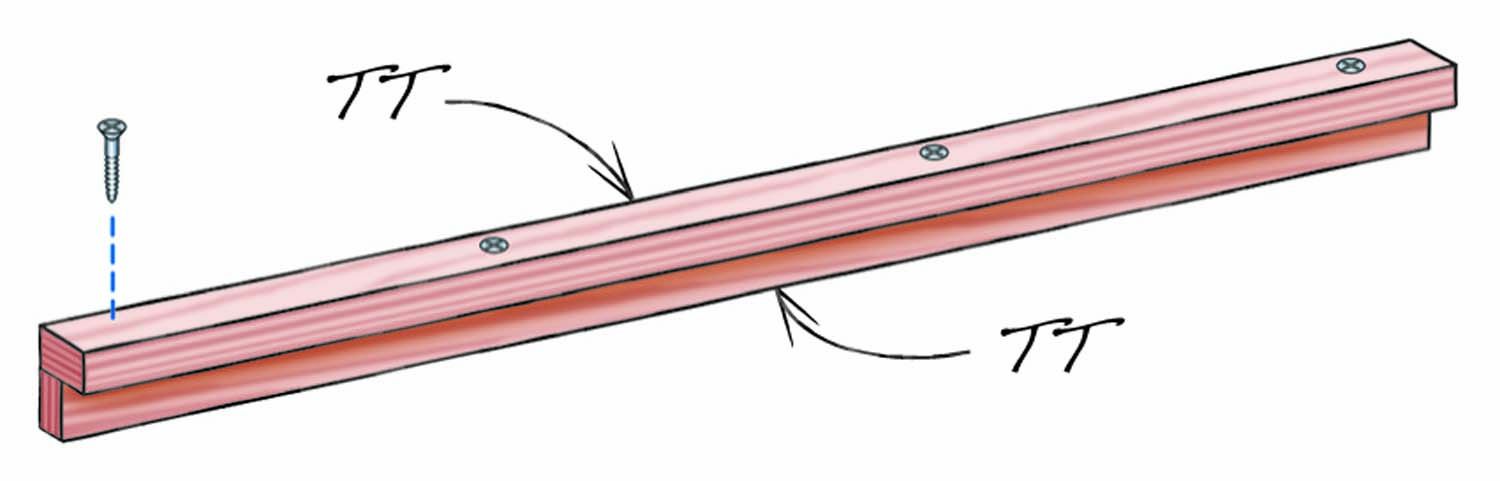

| TT | Divider rail | 4 | Hardboard | 1/4″ x 1-13/16″ x 12-1/2″ |

| Notes: (a) Overall height includes retainers. (b) Plywood thickness is nominal. |

||||

Fig H. Exploded View: Top Cabinet

| Finishing Cabinet-Top Cabinet Overall Dimensions: 27-3/4″ H x 31″ W x 11-1/4″ D |

||||

| Part | Name | Qty. | Material | Th x W x L (a) |

| AAA | Side | 2 | Exterior fir plywood | 3/4″ x 10-1/2″ x 26″ |

| BBB | Top/bottom | 1 | Exterior fir plywood | 3/4″ x 10-1/2″ x 30-1/4″ |

| CCC | Back | 1 | Exterior fir plywood | 1/4″ x 30-1/4″ x 25-1/4″ |

| DDD | Shelf | 2 | Exterior fir plywood | 3/4″ x 3-1/2 x 29-1/2″ |

| EEE | Lip | 2 | Exterior fir plywood | 1/4″ x 2″ x 29-1/2″ |

| FFF | Cleat | 4 | Exterior fir plywood | 3/4″ x 1″ x 3-3/4″ |

| GGG | Door | 2 | Exterior fir plywood | 3/4″ x 15-7/16″ x 25″ |

| HHH | Gallery front/back | 2 | Exterior fir plywood | 3/4″ x 2″ x 29-1/2″ |

| JJJ | Gallery side | 2 | Exterior fir plywood | 3/4″ x 2″ x 8-1/4″ |

| Notes (a) Plywood thickness is nominal. |

||||

Drawers

Photo 5. Install drawer slides in the drawer cabinet box. Spacers make this job easy.

Start by mounting the drawer slides in the drawer cabinet (Photo 5). Fasten the first slide flush against the bottom of the cabinet. Then install spacers to locate the other slides. Mount all the slides flush with the front of the cabinet.

The drawers are simple boxes with applied fronts (Fig. F). The drawer box sides (DD, FF, HH) are rabbeted to house the box fronts and backs (EE, GG, JJ).

Pro Tip

Save time when making rabbeted drawer parts by starting with a wide blank. Cut the blank to the length of the parts. Rabbet the ends of the blank; then cut the parts to width.

Photo 6. Assemble the pullout mixing tray and drawer boxes. The tray is simply a shallow drawer box.

Cut a groove to house the drawer bottom (KK) in every drawer box part. Then assemble each drawer box with glue and screws (Photo 6). Cut the drawer fronts (LL, MM, NN) to final dimensions. They run full-width across the cabinet and mount flush with the bottom of the drawer boxes.

Photo 7. Install the drawer fronts flush with the bottom of the drawer boxes. Only the pullout tray’s front extends above the box.

Use the drill press to drill a screw hole for mounting the knob through the center of each drawer front. Then, working on a flat surface, clamp each drawer front in position and drill countersunk pilot holes through the box for the mounting screws. Next, extend the knob’s screw hole from the drawer front through the box. Then remove the drawer front and increase the hole in the box to 1/2″ dia., so the knob’s short screw will pass through to the back of the drawer front.

Photo 8. Build T-shaped dividers that slide back and forth to maximize the drawers’ versatility.

Screw on the drawer fronts (Photo 7). Then attach the knobs and make the sliding drawer dividers (Photo 8; RR, SS, Fig. G). Butt the drawer slides against the drawer fronts and mount them flush with the bottom of the drawer boxes. Make the pullout tray’s stabilizer (TT, Fig. H) after you install the drawers. It should fit snugly between the back of the tray and the cabinet (Photo 9). Make adjustments as necessary.

Photo 9. Stabilize the pullout tray for use by installing an L-shaped filler that eliminates wobble caused by its drawer slides.

Center the drawer cabinet on top of the flammables cabinet and anchor it with screws. Then install the retainers (W, X).

Shelves and doors

Cut the door cabinet’s shelves (DDD) to final size and glue on the lips (EEE). Screw cleats (FFF) to the cabinet sides and then screw the assembled shelves to the cleats, so they won’t fall.

Photo 10. Mount each door using wrap-around hinges. Stand the door on shims to position it at the correct height.

Cut the doors (GGG) to final dimensions. Mount wrap-around hinges (see Sources) on each door, located 2-1/2″ from the top and bottom. Then attach each door to cabinet (Photo 10). Install a cupboard latch on the outside and a catch behind the left door on the inside (see Sources). Fasten the steel panel to the door (Photo 11; see Sources). Before mounting the panel, lay it flat and use an awl or a nail to punch holes for the screws.

Photo 11. Mount a steel panel on the door for holding brushes and other lightweight tools. Pan head screws

As before, center the door cabinet on top of the drawer cabinet and anchor it with screws. Then install the retainers (PP, QQ).

Sidebar: Avoid a Devastating Fire

Here’s a recipe you should never try: Pour some boiled linseed oil on a rag, wad it up and cover it with more rags or sawdust. Then wait 2 to 4 hours.

Here’s a recipe you should never try: Pour some boiled linseed oil on a rag, wad it up and cover it with more rags or sawdust. Then wait 2 to 4 hours.

So, what’s the problem? Fire. Every year, oily finishing rags are sited as the cause for disastrous, even deadly, fires. Every woodworker is taught that such rags can spontaneously combust. But perhaps not everyone understands that there’s an important difference between an oily rag that can burn only when ignited by a flame or spark and an oily rag that can spontaneously ignite.

The curing process that occurs in some wood-finishing oils—especially boiled linseed oil—is a heat-producing chemical reaction that can easily lead to a spontaneous combustion fire. Because boiled linseed oil can be an ingredient in many oil-based stains and finishes without being listed on the label, the best practice is to be careful with all oily rags.

Fortunately, the danger of a fire caused by oily finishing rags is easy to avoid: Simply lay every oily rag out flat, so there’s no chance for heat to build up as the oil cures. If there’s any chance that a breeze could move the rag, place a weight on top to make sure it stays put. Hanging an oily rag over a rail or the edge of a garbage can is very safe as long as you secure it with a clothespin or spring clamp. When the rag feels stiff and dry, it’s safe to throw in the garbage.

Putting oily rags in water or storing them in a steel fireproof container are often recommended for temporary storage. These methods will effectively prevent a fire—until the rags are removed. Then, because the rags are very likely to contain uncured oil, the risk of fire remains.

Bio

Kevin Southwick is a wood finishing specialist and furniture restorer/conservator. Learn more at southwickfurnitureconservation.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.