We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

This is an excerpt from The New Traditional Woodworker by Jim Tolpin.

In traditional Western-style woodworking, the workbench was central to nearly all the woodworking processes. This is where the artisan planed surfaces and trued edges; ripped and crosscut short lengths of stock to size (with smaller-sized panel saws or bow saws); made precision cuts for joints (with backsaws); pared joints; chopped out mortises and put together smaller assemblies such as drawers. As a new traditional woodworker, this is where you will be spending more than 90 percent of your time as well. As you might rightly assume, it’s crucial to choose the right type and size of bench to accommodate you and the kind of work you intend to do at the bench. There are many styles of benches to choose from.

In traditional Western-style woodworking, the workbench was central to nearly all the woodworking processes. This is where the artisan planed surfaces and trued edges; ripped and crosscut short lengths of stock to size (with smaller-sized panel saws or bow saws); made precision cuts for joints (with backsaws); pared joints; chopped out mortises and put together smaller assemblies such as drawers. As a new traditional woodworker, this is where you will be spending more than 90 percent of your time as well. As you might rightly assume, it’s crucial to choose the right type and size of bench to accommodate you and the kind of work you intend to do at the bench. There are many styles of benches to choose from.

Some, like the low-slung and massive Roubo and English-syle benches, lean more toward accommodating planing and coarser joinery work (such as chopping out mortises) while the typical northern European “Continental” benches with their higher stature and large shoulder vises lean more toward accommodating cabinetmaker’s performing finer joinery (such as sawing out dovetails and other close, precise work). Of course, any type of bench can be set up with fixtures (such as vises, various planing stops and sawing guides) to allow most any kind of process.

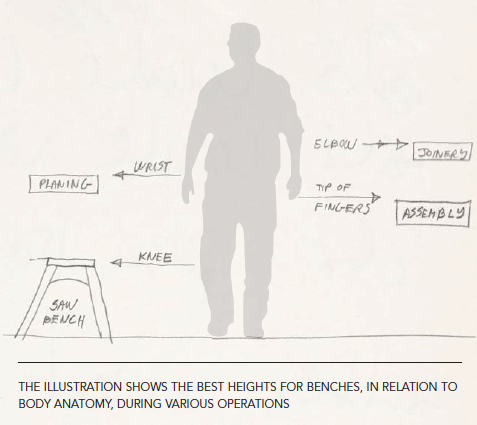

I think the most crucial thing to determine about a bench is to find the right work surface height. It’s got to be low enough so you can plane boards comfortably with your upper body weight bearing above the plane (and low enough so you can chop out mortises with your shoulders well above the mallet), yet the bench must not be so low that you’ll find it uncomfortable to stand and make precision saw and paring cuts. In these latter operations the bench must support the wood high enough so you can see the cut lines and so you can operate the backsaws, paring chisels and trimming planes without stooping. Unfortunately, because of the shape of the human body, it’s literally impossible for a bench to meet all these requirements.

There are however, some ways around it. When you are young, strong and flexible, it’s not such a problem to work at a bench whose height falls somewhere in the middle of the two ideals. For most people, this height comes to wrist height (see the drawing at top left). For myself, I find that I simply can’t work with this compromise. A height that allows me to put my fairly light frame to bear over a handplane (and my aging muscles need all the help from my body mass) is far too low to hold work where my aging eyes can see the cut lines for precision work. And my back is long past the point of holding up for more than a minute or so of stooping.

There are however, some ways around it. When you are young, strong and flexible, it’s not such a problem to work at a bench whose height falls somewhere in the middle of the two ideals. For most people, this height comes to wrist height (see the drawing at top left). For myself, I find that I simply can’t work with this compromise. A height that allows me to put my fairly light frame to bear over a handplane (and my aging muscles need all the help from my body mass) is far too low to hold work where my aging eyes can see the cut lines for precision work. And my back is long past the point of holding up for more than a minute or so of stooping.

As you’ve already discovered (in the discussion above about my shop layout) my solution for this problem was to build two benches — one dedicated to planing and coarse joinery work (such as chopping out mortises) and the other for precision work (such as cutting dovetails). As you can see in the drawing at top left, the planing bench comes up to wrist height while the joinery bench is at or just below elbow height. The saw bench for coarse ripping and crosscutting comes to knee height (more on this bench later). I set the benches a step away from each other and therefore just a step away from the tools used at either of them. You should, of course, take these height suggestions as a starting point since everyone’s body frame and musculature is unique.

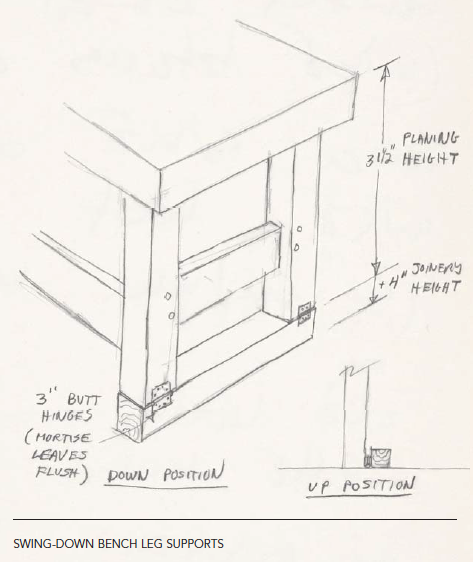

If you don’t have the time, space or inclination to build separate benches for planing and joinery, there is another solution available (other than being young, that is). It’s a simple matter to rig a pair of swing down leg stanchions that will allow you to quickly change the height of the bench as necessary. To use the stanchions to raise the bench, you lift one end of the bench at a time, allowing gravity (and perhaps a little help from your foot) to let the stanchions swing down under the fixed leg support base or posts. Reverse the procedure to lower the bench.

If you don’t have the time, space or inclination to build separate benches for planing and joinery, there is another solution available (other than being young, that is). It’s a simple matter to rig a pair of swing down leg stanchions that will allow you to quickly change the height of the bench as necessary. To use the stanchions to raise the bench, you lift one end of the bench at a time, allowing gravity (and perhaps a little help from your foot) to let the stanchions swing down under the fixed leg support base or posts. Reverse the procedure to lower the bench.

The bottom line, however, is that no matter which type of bench you choose, it should meet three fundamental criteria. First: The top should be dead flat (if it isn’t, and it’s wood, you can flatten it with hand planes). Second: The bench should be sturdy enough to not shake when you plane or saw a board on it. Vibration absorbs energy and slows the process. Third: It should be the right height for the work at hand.

– Jim Tolpin

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.