We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

My students learn two things about me very quickly: I care deeply about their education, and I care just as deeply about the tools we use while learning together. In our woodworking program—which begins in fourth grade and continues through middle school, eighth grade, high school, and eventually the junior–senior levels—we do not skimp on tools. I buy the best I can, not because I enjoy seeing beautiful tools hanging from the shop walls (though I admit I do), but because good tools last longer, hold their edge better, and—perhaps most importantly—invite admiration. They cultivate respect for the craft and for the art of toolmaking itself.

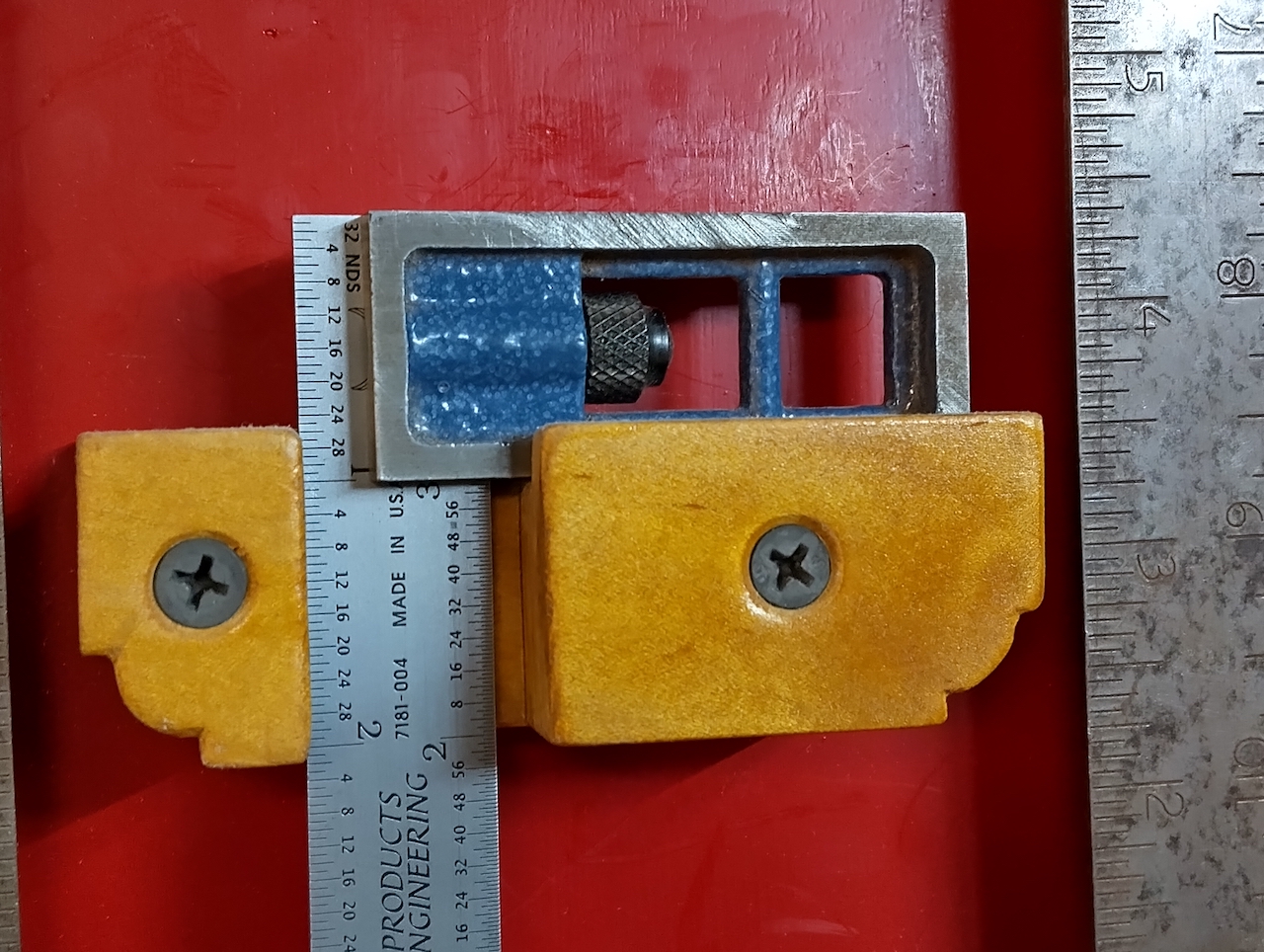

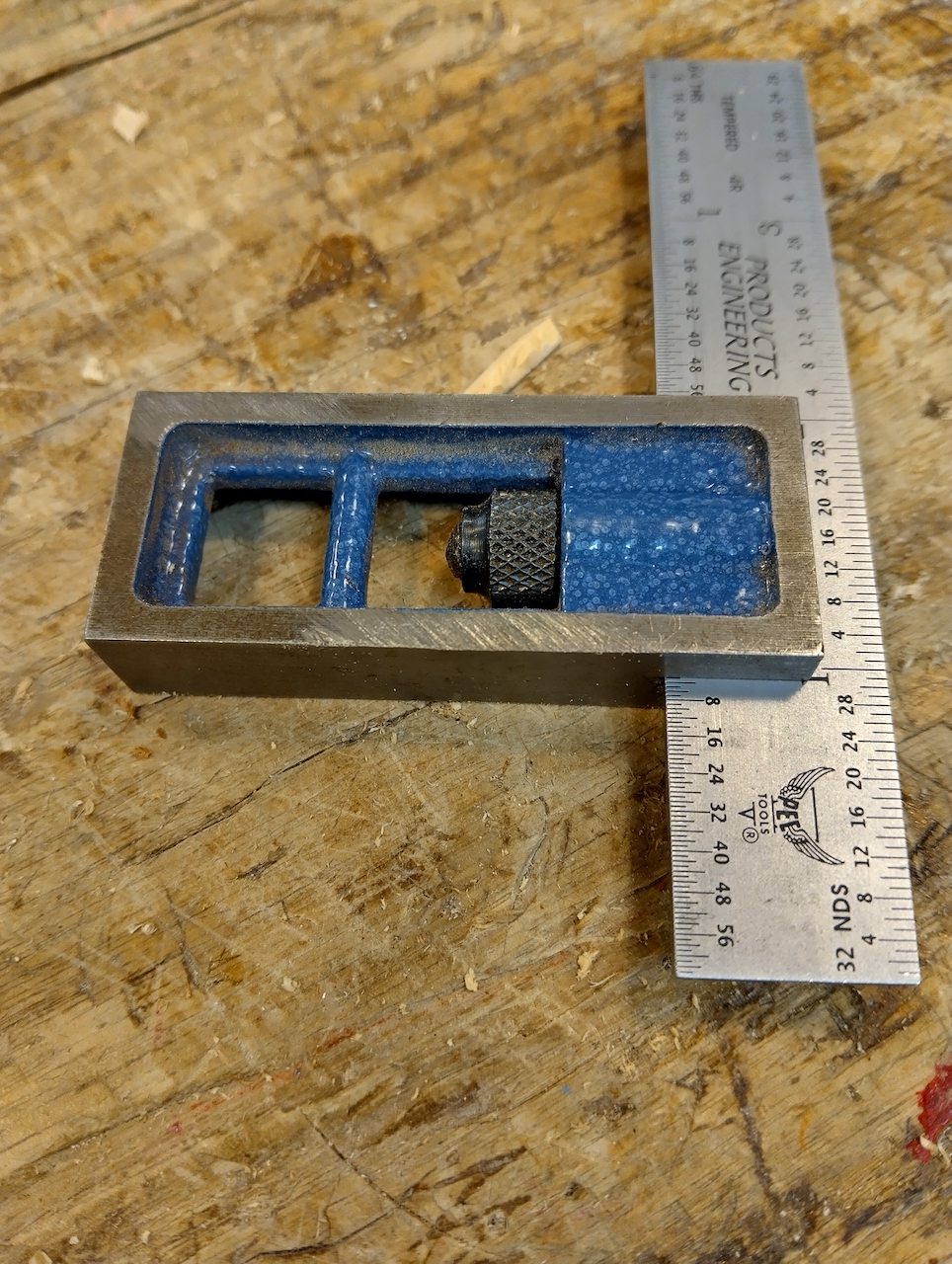

Over the years, I’ve built dedicated holders and caddies so our tools aren’t dumped into drawers where they can rattle and nick each other. One of the tools I especially enjoy seeing in its place is a small 4″ PEC tri-square, U.S.–made, a remarkably accurate little tool I purchased ($49) from Taylor Toolworks a few years ago. I built a tiny caddy for it and hung it beneath our combination square on the red marking tools panel in the school shop.

We don’t reach for it often—students tend to use the full-size combination square for most marking tasks—but the little PEC square shines when we calibrate machines. For that reason alone, it has been worth every penny.

This morning, during one of my occasional “tool inspections,” I reached for the PEC square to check for rust. These spot-checks are part of my routine: Does a compass need a sharper pencil? Does a combination square’s tightening knob want a drop of oil? Are any marking knives missing from their slots? Small habits that keep a school shop healthy.

But the moment I picked up the tri-square, I felt something was wrong. The head felt coarser—much coarser—than usual. The smooth, matte cast-iron face I knew so well was suddenly foreign under my fingertips.

I looked closer.

My stomach dropped.

Deep grooves—ugly, unmistakable, and purposeful—scarred the head. Burrs stood proud along the edges. The beautifully machined face was no longer parallel. It looked as though the square had either met the platen of a belt sander or had been raked repeatedly with a file. Neither possibility was comforting.

And, of course, the questions came next:

Was it an accident?

Did a student place it on the belt-sander table to check for square, not realizing the risk?

—or—

Did someone intentionally take a file to its face?

I’ll never know. What I do know is the feeling—one that any teacher of shop craft understands instantly. It’s the feeling of being smacked in the face. Because we talk about tool respect constantly. Because we model it. Because we invest in these tools for them.

Tool abuse is also one of the very few moments when I ever raise my voice in the classroom. If I see a rasp being carelessly clanged against a file, or a student shoving a rasp back into the drawer without aligning it into its dedicated groove so the teeth won’t touch their neighbors—those are the moments when I intervene sharply. The lesson isn’t about the tool alone; it’s about stewardship, responsibility, awareness, and pride in one’s craft.

The accompanying photos—of the damaged PEC tri-square, its dedicated spot on the marking-tools panel, and the rasp drawer where each tool nests separately—illustrate the larger message: tools deserve attention, care, and respect.

With the vast majority of my young students, I am proud to say that I can teach and nurture proper tool etiquette and respect—especially in a time when so many young Americans grow up without an appreciation for craftsmanship, self-reliance, materials, or hard work. I only wish I could reach all of them, all of the time.