We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Wedging joints adds great strength, but it also is risky. A wedge can split the work, it can fail to dive into the tenon (sometimes popping out of the tenon), or the tenon itself can split when you hit it, making a mess of things.

Here are three things I do to reduce the risk.

1. Make lots of wedges. When I make wedges, I usually make at least 100 so I have lots of them on hand at assembly time. Every wedge is a little different. You might need a thin one for a tight tenon or a big fatty to close up a big gap. I like to make my wedges so they have a 4° included angle at the tip.

2. Add a secondary bevel to the wedge. Right before I drive a wedge home in a tight tenon, I use a knife to carve a quick secondary bevel on both faces of the wedge. This secondary bevel helps start the wedge in tight spaces.

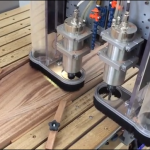

3. If the tenon is still too tight, open it with a chisel. Sometimes even a perfect wedge will fail to open a tight tenon. So I help things along with a chisel. Take a chisel that is the same width as the diameter of your tenon and use it to split the tenon open above the surface of the work. This almost always does the trick.

Last of all, use hide glue. It’s reversible so if you really muck things up, you can apply some heat and moisture, take the joint apart and try again.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hi Chris

Your tip on wedging tenons is quite helpful I will use when making windsor rockers which I love to make, but my question is about an article you wrote a few years back using black bison wax as a finish. I have used the technique on several of my projects with great results and i am about to use it on a kitchen table I am making for my daughter. The question I have is … after 2 coats of wax will this be enough to stand up to a kitchen table versus 3 small children?. Should I or could I add another finish on top of the wax for more protection?

Any suggestions would be much appreciated.

Thx

Joe

In order to prevent split tenons, I’ve successfully used Tage Frid’s technique of drilling an 1/8″ hole along the base of the saw kerf.

Hi Chris,

I have a question unrelated to above but am hoping you can help–i’m sure you can!

I am a (very) novice “woodworker”, if i can be allowed to use that word–might be more appropriate to say i have an interest in woodworking and am looking to develop my skills. My complete works so far consist of an adirondack chair that turned out pretty decent.

Anyway…my next project is a workbench, and right now i’m thinking Roubo type. I’m unsure I’ll be able to find a large enough slab for the bench top, so am thinking i will have to glue up a slab. i like the look of the through tenon to attach the leg posts to the top. This may be a naive question, but am wondering if that can be done with a glued up slab or if i should find another way to attach the top to the leg posts, and if so which would you recommend?

Thank you for your help.

Sam

These 3 tips are helpful to me. Could you comment further…

Since reading ADB I have made 4 projects with staked legs. The Veritas tenon maker/ reamer bit combo is awesome.

After verifying that all goes well with the dry-fit, I have used a .015″ dovetails saw for the kerf, a thick kerf band saw and a really thick kerf panel saw. All work and look a little different. Is there a kerf width that represents “ideal” for strength.

Also- the tenon pictured above looks to be proud of the seat about 1/4″ but I have seen tenons with wedge standing 1″ proud or more.

Is this simply a case of whatever I feel like doing at the moment or are there logical reasons for doing it one way or another. Thank you.