We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

In good company. I worked alongside some timber-framers to cut and raise a new workshop frame recently. No doubt joiners and carpenters in London worked together at times, but disputes and controversy result in better documentation than cooperation.

Early modern records show guild regulations in London.

Early 17th-century London tradesmen were protective about their work, carefully keeping an eye on any interlopers to their craft. A dispute arose in the early 1630s between London’s carpenters and joiners, and in my last column (June 2016, issue #225), I outlined the works the city aldermen assigned to the joiners in an attempt to settle this dispute. What of the carpenters? They did not take the aldermen’s decision lying down, that’s for certain.

The aldermen’s decision essentially skips right over carpenters’ principal work, assuming perhaps that it’s a given they frame the buildings. Instead they went on to focus on furniture and smaller works. To begin, carpenters get:

“All Drapers Tables, all Tables for Tavernes Victuallers Chandlers Compting house Tables and all other Tables made of Deale Elme Oake Beeche or other woode nayled together without Glue except all sorts of Tables either nayled framed or glued being moveable.”

“Being moveable” is the key here – the joiners make moveables, what we would call furniture today. The carpenters make the tables and counters that are built-ins, so in effect “non-moveable.” And yet, small moveable stools for various uses (“Sesterne Stooles washing Stooles bucking Stooles”) went to the carpenters, as long as “they not bee turned feete.” The forms (long benches) fall under similar guidelines regarding the joinery and turned elements.

The carpenters get the dividing of warehouses, chambers and other rooms, “unwainscotted and unpannelled with slitt or whole deales or any other materials Wainscott excepted and except all pticons (partitions) grooved glued battened or framed.”

Detailed Allowances

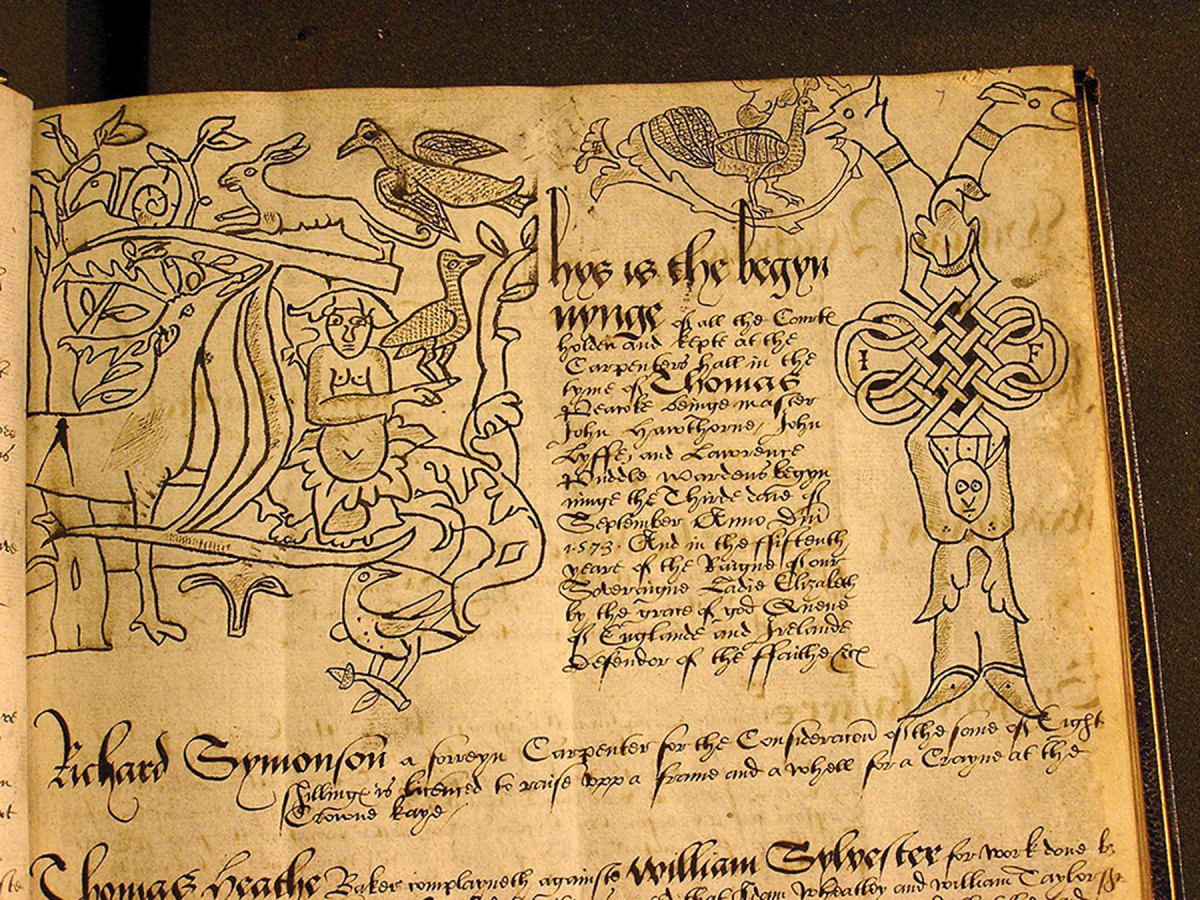

Early modern doodle. Being the record keeper for a large London company in the 16th century could at times be less than exciting. That’s one possible explanation for this drawing found among the Carpenters Company records. Or is it that, being prevented by regulation from carving works like this, one tradesman found another creative outlet?

The carpenters had something to say about this, and they weren’t bashful. In a petition with the usual legal preamble, they put in writing their main works: “The building erecting and repairing of all manner of howses & edifices whatsoever of any kinde of timber whatsoever.” That’s pretty clear – “all manner of houses…whatsoever.”

Their petition is quite lengthy and includes great detail. Among their works are: “The framing and setting upp of all manner of timber windowes…in howses built of stone brick or timber…all manner of staires that are to be done of timber board or plancks.”

Among many other works, they claim as theirs and not the joiners’ “all manner of penthowses…of all manner of postes and seates at gates or Dores…the making of all cases for the enclosinge of cesternes…all manner of sheds and hovells.”

Being a joiner myself, I’d be glad the carpenters get larger works such as “Wharves Camshedds Cranes & bridges of timber and piling and planckinge of foundacons for Wharves and Bridges.”

And what 17th-century document would be complete without some nice corporal punishment? The carpenters make “ladders stocks cages and whipping postes.”

Response to Joiners

Same work, different size. Driving tapered wooden pins (trunnels) to secure drawbored mortise-and-tenon joints is the same regardless of the scale. I think of this as a giant joined chest. I tapered the pin with the hatchet, then flipped it around and used the poll to drive the pin home.

There are many other works listed in the full document, but beyond that the carpenters also sent revisions to the joiners’ work. The whole document becomes redundant, but one of the carpenters’ concerns is that “…there is almost noe carpenters worke to be done but they may and doe use the Iage (gauge?) and nailes both in invented and to be invented which being allowed to the Joyner they will doe any Carpenters worke. And therefore wee desire that that article maie be soe qualified & explaned that the Joyner shall not intermeddle in the Carpenters worke.”

Outside the City

‘Orbis Pictus,’ Comenius, 1658. “The Carpenter squareth Timber with a Chip-Ax, whence Chips fall, and saweth it with a Saw, where the Saw-dust falleth down. Afterwards, he lifteth the Beam upon Tressels, by the help of a Pully, fasteneth it with Cramp-Irons, and marketh it out with a Line. Thus he frameth the Walls together, and fasteneth the great pieces with Pins.”

It’s easy to read too much into these “guild” regulations and city restrictions. One thing to keep in mind is that outside London, sometimes just a few miles outside, it was easier to get away with crossing trade boundaries.

Further afield, we get some insight into one carpenter’s repertoire. The record book of Henry Best, a farmer of Elmswell, Yorkshire, shows an entry from April 1620 in which Best “Agreed with Matthewe Carter, for paylinge the swyne stye with sawen ashe pales, to give him for his worke 9d [per] yeardes, and hee is to sawe them, and to saw the rayles and postes, and sett them in a groundsell, and rabbitt them into the rayle above; agreed also with him to pale the yearde, and hee is to sawe the rayles and postes, and to have 4d per yearde, for his labor, and for making Austin’s howse. 20s.”

‘Timmerman,’ Jan Luyken, 1694. An auger, one or two chisels and a mallet is all you need to chop mortises for a house frame. And strength. Lots of strength.

All that is well and good; carpenters should make pigsties – what self-respecting joiner would deign to do so? But in 1623, Best “Bargained with Matthewe Carter and John Carter his sonne, of Greate Driffeylde, carpenters, to digg upp a walnutt tree of myne, and sawe it into 2 ynch and a halfe plankes, and the rest of the small peeces into such peeces it is fittest for; and to make mee two chayres, one for my selfe, and the other a lesser, well turned and wrought, and I am to give them for doing these things above mencioned, workman like, 10s in money, a bushell [8 gallons] of barley, and a pecke [2 gallons] of oatmeal, and give them in money 3d for their godspenny.”

So – carpenters making a pigsty at one point, and then well-wrought, turned chairs of walnut. That’s the whole spectrum of period woodwork in a (wal)nutshell. No joiners or turners need apply.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.