We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

A modern approach to joinery yields perfect miters.

A modern approach to joinery yields perfect miters.

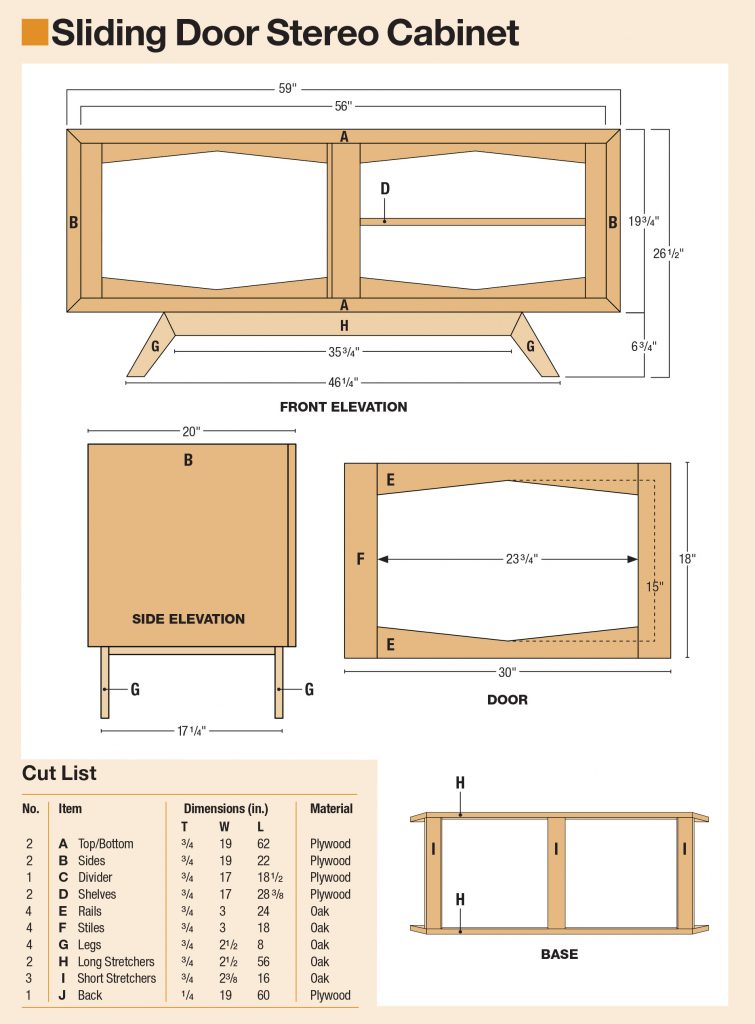

Project #2009 • Skill Level: Intermediate • Time: 3 days • Cost: $250

I have a definite affinity for Mid-Century furniture. There’s just something about those refined forms with clean lines and angles that really get me. When it came time to build a cabinet for my stereo equipment, I knew I wanted a simple form with a couple design flourishes. I also knew I wanted to match some of the other furniture and trim in my circa 1964 home. Through a couple design iterations, I landed on a mitered plywood box sitting on tapered legs with sliding frosted glass doors.

With judicious use of pocket hole joinery, a few dowels and mitered splines along with off-the-shelf slider track, construction is pretty straightforward. In fact, I did this whole build using only a drill, router, miter saw and track saw. It took a little practice and some careful measuring to cut the 45° ends of the case, as well as thinking outside the box to cut splines with a track saw, but the result was well worth the fuss.

Exploded view and cutlist at bottom of article.

Creating the Case

Start with constructing the case. Rip four pieces of 3/4″ plywood at 19″ wide and slightly overlong (about 62″ for the top/bottom and 22″ for the sides). Next, cut the mitered ends. Using 45° crosscuts, trim the top and bottom pieces of the case to 59″ long, and the two sides to 191/2″ long. I used a track saw for this procedure, and it was eye-opening. On panels this size especially, the track saw makes for easy, consistent miters, and the boards can be gang cut (aligned next to each other under the track) to get them as close to identical as possible. It took a little experimenting to dial my saw’s bevel to exactly 45°, but once that was locked in, the cuts went quickly.

After your pieces are cut to width, miter the ends of the case top, bottom and sides. I gang cut the top/bottom and sides together so that they’d be the exact same lengths.

Using a track saw to make 45° miter joint takes a little practice. I found keeping my left hand on the saw/track helped counteract the saws tendency to tip.

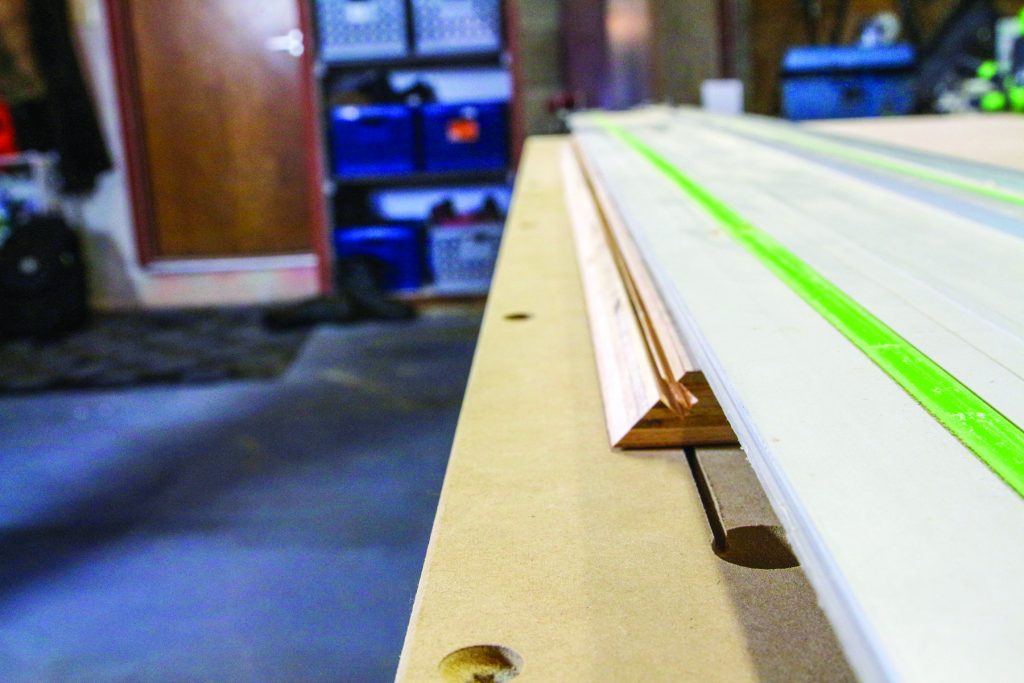

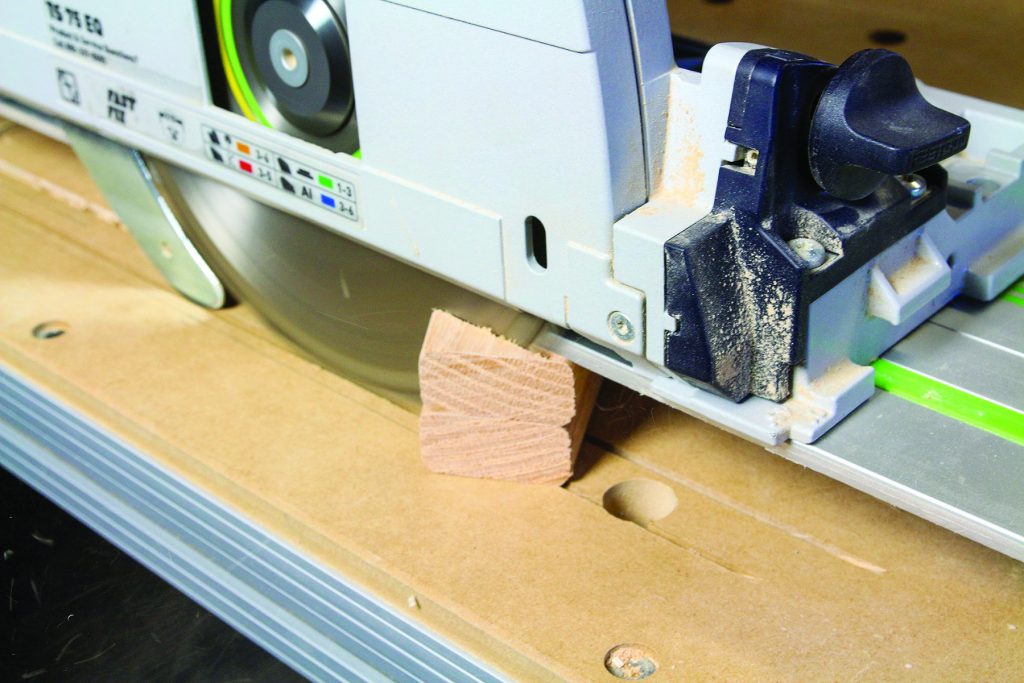

Cutting grooves for splines on a track saw is a fairly straightforward task. These measurements are for 1/4″ plywood splines, though you may need to adjust the width of your groove slightly for your specific spline material. A track saw table or a waste board with a clearly defined cutting line makes the process repeatable for all eight grooves you’ll need to cut.

Start by setting the front of the mitered edge 1/4″ past the outside edge of your normal 90° cutting groove in the table. With the track saw at 45°, set the blade depth to 5/8″, then cut your groove the entire length of the mitered edge. This is your first pass. For the second pass, move the front of your board to 3/8″ past the outside edge of the table cutting groove, and set your blade depth to 9/16″. Make your second pass, then test fit a piece of plywood. Any waste in the middle can be cleared out with a chisel.

Flip your case parts over and then cut grooves for your splines. After some test cuts, I settled on two passes at slightly different depths, moving the panel outward for the second cut. Once you have your depth/width dialed in, make some reference marks on your cutting surface.

The resulting groove is about 1/4″ deep and 1/4″ wide, sized to fit 1/4″ plywood offcuts.

I ended up with a sliver of material left in between my cuts that I sliced out with a utility knife.

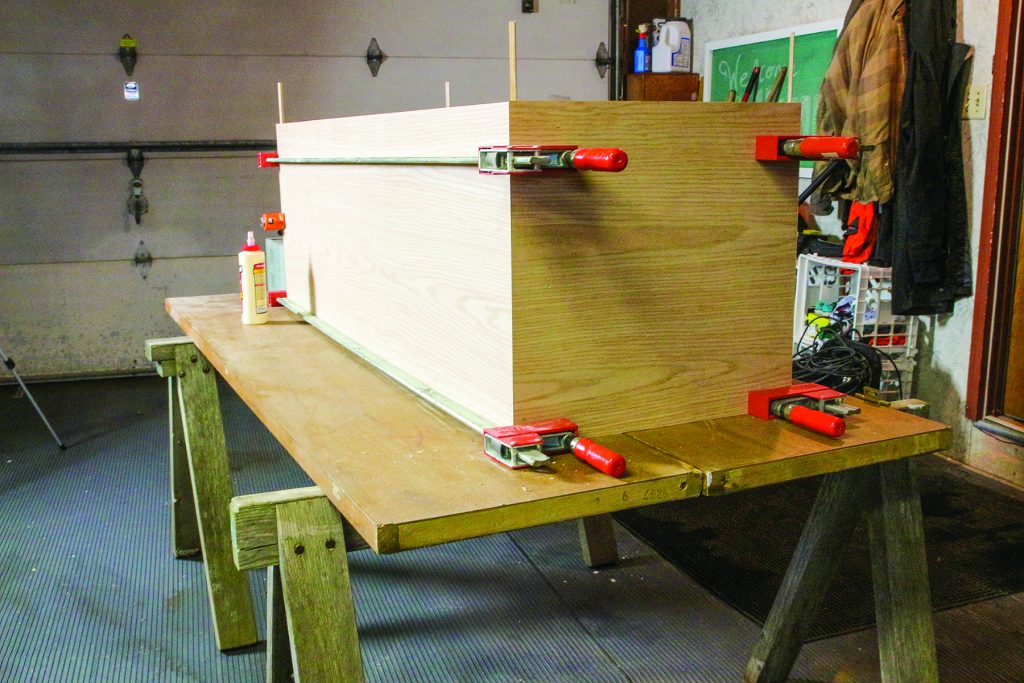

In order to make sure the adjoining sides aligned exactly, I numbered the edges and gang cut them sequentially. After cutting the splines you’ll want to do a dry fit of the case and rehearse your clamping. The splines help align the miters, and I was able to get by with four long clamps and a few shorter ones to help take some bow out of one of the pieces of plywood. Disassemble, then go ahead and glue everything up. I used Titebond III for a 15-minute open time. Having a buddy helps this part be less stressful.

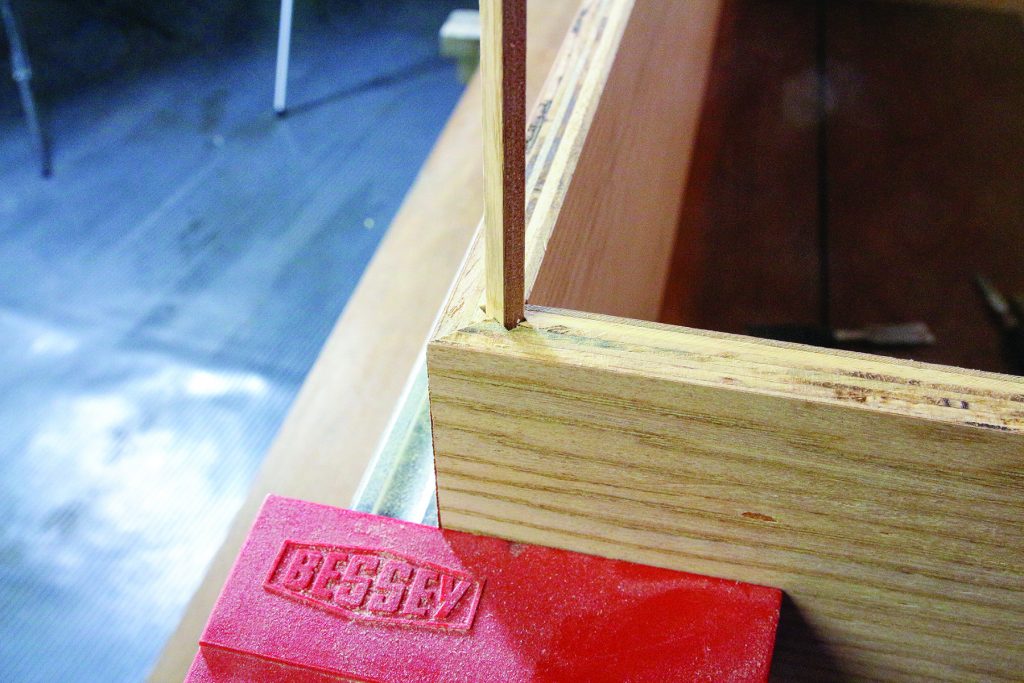

After a dry fit, it’s time to glue up the carcase. I use an old toothbrush to spread a healthy amount of glue on the joint and in the groove.

Insert the splines and add clamps. I left the splines long to aid in aligning the parts, then trimmed them.

This case maxed out the capacity of my clamps (60″). With the alignment help from the splines, I was able to get away with just four clamps on the whole thing.

Back and Interior

Once the glue has cured, install a 3/8″ rabbeting bit on your router and set the depth to slightly more than the thickness of the back plywood. Cut a rabbet around the rear edge of the case so the back sits flush. I clamped an offcut of plywood to the edge I was working on to get more material to rest the router on. After getting a lot of chipout on the first foot or so of cutting, I switched to climb-cutting with the router. It yielded a much better edge but took more control and was slower going.

After the glue has cured on the case, rout a 1/4″ recess around the back for the back panel.

Then, square the corners of the recess with a chisel to accept the 1/4″ plywood back

For the sliding doors, I purchased a 6′ extruded aluminum track off of the internet. After cutting it to length on the miter saw (yes, I use my miter saw to cut aluminum), I did a test fit installation so I could take measurements for the center divider and shelves.

The divider and shelves were all built using plywood with solid oak edging. The plywood pieces for the shelves were rough cut to 29″x17″ and the divider to 19″x17″. I cut 3/4″ oak edging about 13/16″ wide, then glued and clamped it to the front edges of the plywood parts. After the edging was installed and flushed up (just some quick sanding), the divider was then cut it to 16 3/4″ deep and 18″ tall, and the shelves to 16 3/4″ deep and 28 3/8″ long.

To install the divider, drill a pair of pocket holes for the top edge, then align it to the center of the case. Fasten the top screws, then flip the case over. On the underside, drill a few countersunk holes and install screws to hold the divider tight. With the divider installed, cut the 1/4″ plywood for the back to size and install it with finish nails.

Tapered Legs and Base

The front and back of the base is constructed from two 6’ oak 1x3s to keep grain continuous. First, cut two legs at 8″ each off the ends of the board. To taper the legs, measure 1 ½” on one end of the board, and draw a line to the opposite corner. Use the track saw to cut the taper, then cut a 35° miter on the wider end of the leg. Both legs can be cut at the same time. For the longer middle pieces, cut a 25° miter on both ends. Then, roundover all four edges of each leg, and the bottom edge of the middle board with an 1/8″ roundover bit.

After cutting the leg stock off the ends of my two 1×3 base rails (to keep the grain continuous), I tapered the legs with the track saw

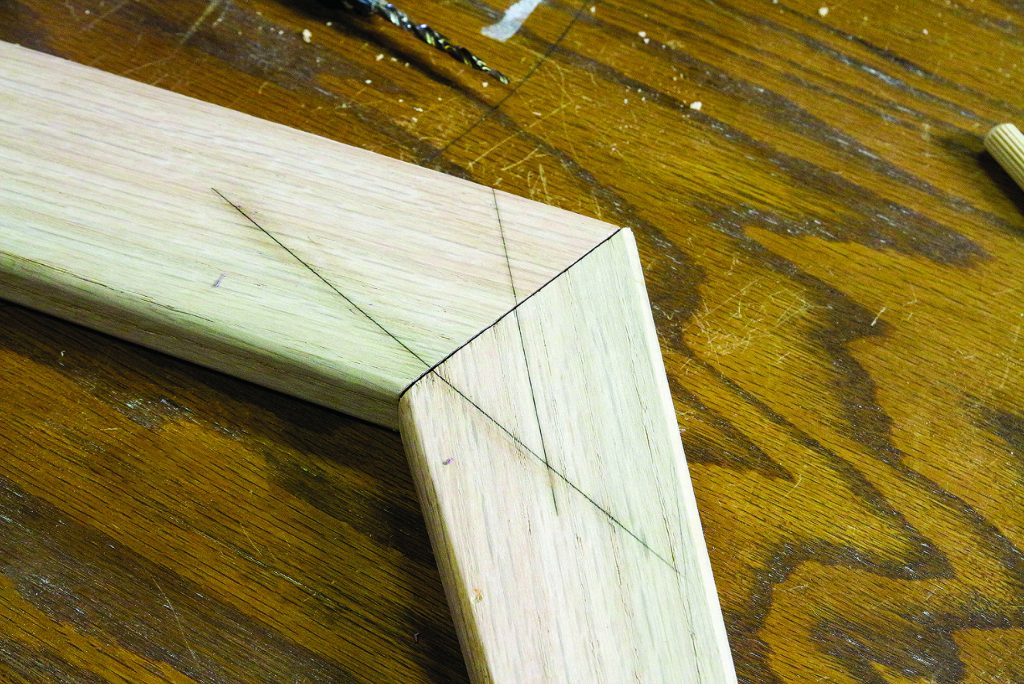

The legs are assembled using a dowel joint and a countersunk screw. The dowel reinforces the miter, while the screw pulls the miter tight. Lay out your leg assembly so you can mark where the joinery is going. Don’t worry about tops of the legs not aligning perfectly, you’ll trim them when you’re done. The dowel is going to be placed near the inside corner of the leg, and the screw will come in from the top. Mark the lines on the piece where each of these will go as demonstrated in the photos.

The leg to rail connection on the base is made with a dowel and a screw (driven in from the top). Lay out the locations for the dowel and screw, making sure they don’t overlap.

With your layout lines in place, drill the holes for the dowel using a dowel jig and test fit your assembly. With everything aligned, you’re going to drill a very small pilot hole for your screw. Glue up both sides of the joint and assemble with the dowel. This step will allow you to carefully hold everything in place while drilling your countersunk hole. With the hole drilled, install the screw, making sure it pulls the joint tight. Repeat for each leg.

I used a dowel jig to drill mortises for the dowels

Add glue to the joint and assemble. Pre-drill and countersink a 3″ screw into the leg joint.

After the glue is dry, the final cuts can be made on the track saw. First, trim the small bits on the top by setting the body flush to the edge of the track. Then, flip the legs around and align the bottom of the legs to the edge of the track. Cut the tips off so the feet will sit flat on the floor.

I used the track saw to level the feet for the base. The long track gave a straight reference line to cut the perfect angle on the bottoms.

With the front and back leg assemblies complete, you can build the crossmembers. Rip three 16″ long boards to 23/8″ wide. On two of the boards, rip a 30° miter along one side. Using the same roundover bit as before, rout the bottoms of the angled boards. The remaining board will not be visible and does not need to be rounded (though you certainly can if you wish). Drill pocket holes on both ends of the “inside” of the angled boards (the wider side) and on both ends of the middle crossmember.

Now line everything up for a test fit. The angled crossmembers match the angle of the legs. Add a bit of glue to the ends, then install with screws. The final step for the base is to drill a handful of pocket holes along the inside of the frame to attach it to the case.

Add the short stretchers to the base with pocket holes. The outside stretchers are angled to match the legs.

I clamped the whole base up on my assembly table to make sure it was flat/square, then drove the final screws for assembly.

The Doors

The doors are what really give this piece its midcentury feel. They went through several redesigns before settling on the final look. I wanted to incorporate something in the style of Arne Vodder—taking his iconic sidebar drawer shape and rotating it 90°, while also incorporating the handle style from a Charlotte Perriand cabinet I had found online.

After playing with a few different forms and construction methods, I realized that Vodder had the right idea all along and returned the overall form back to the original horizonal layout, with the handle built in such a way it appears to be from one solid piece of wood.

Each door is constructed of two matching rails, a handled stile, and a plain stile. The plain stile is simply a 3/4″ solid oak board cut to 3″ wide and 17″ long. Things start to get a bit more interesting for the other parts though.

The doors are made from 1x oak boards. I grabbed 1x8s from the home center because they had the most straight grain.

With the doors especially I tried to stay away from flatsawn (cathedral-like) grain. The skinny piece (with the wacky grain) was scrapped.

With all the door parts cut to width, I cut them to their finished lengths with my miter saw, cutting pairs at a time to keep things as precise as possible.

For the handled stile, I used a 17″ long wider board that I could make a handle from each side of to make my cuts a little easier. First you’ll use a cove bit to route the initial shape on both edges, then you’ll cut the angles for the handles.

The handle shape, when complete, will flow from the bottom edge of the style to the flat plane in the middle, then back down again. When oriented correctly, the shape will be almost like a mesa. From the bottom of the stile, mark a line the same depth as the cove up 3 3/4″ to the outside edge. Repeat on top, then cut the corners off on the track saw.

Flip the board so the cove is facing up. Measure and mark 3/4″ from the bottom of the cove, and cut the handles off the board. The handle piece is then rotated so the mesa faces upward, and edge glued to a 2 1/4″ wide board of the same length.

The rails start as four uniform 32 3/4″ 1x3s. Mark the centerline on each board, then make a mark 1 1/2″ inches from the bottom. Draw a straight line from each top corner through the center mark on your board. Cut the top triangle out of the board using a jig saw or band saw. The cut doesn’t need to perfect. To create uniformity, line up and clamp all four rails together, then shape using a belt sander so they all match perfectly.

I traced out the shape of the rail, then rough cut it with a jig saw.

With four rails rough cut to shape, I clamped them all together and used a belt sander to make them uniform and refine the shape.

The pulls are made with a cove bit in a router. With a wide board for safety, I cut coves on both sides.

Then, I trimmed off the ends of the coved parts with the tracksaw and cut the handles from the wider board. You can see the cut marked in pencil here.

Here, you can see how the handle fits into the door assembly.

Glue the handle to the stile. Once it’s out of the clamps, refine the shape with rasps and sandpaper.

With your rails and stiles built, it’s time for assembly. Drill pocket holes on the inside of both ends of the rails, then get out some clamps to lay everything out. I used a small amount of glue on each joint then clamped it together so it could briefly set. To keep things flat even with the handle pointed down, I braced the pieces on my work surface with scrap bits of 1×3. With the glue helping hold the joints in place, install the screws.

The completed rails and stiles are joined with pocket holes (which are then plugged).

Once the doors are assembled you’ll want to ensure they fit in the case correctly. There will most likely need to be some hand shaping done at the top and bottom of the handles so they sit in the rails without catching.

The final step of the doors is to route the rabbet for the glass. I used the same bit I had used for the back of the case and cut a rabbet along the inside edge of the door.

Order of Operations

I decided last-minute in the process to do a glass insert instead of plywood on the doors. This raised some small complications—namely that my pocket hole locations prevented me from clearing out enough wood for a rectangular piece of glass. My local hardware store was able to cut the glass in the shape of the opening, but some places do charge more for each cut they make. Given the location and use of the piece, I chose double strength glass, though safety glass or even acrylic are both good alternatives if you have children.

The hardware store did not have frosted glass available, so I used a frosted glass spray. It’s not the easiest method in the world—I had an issue with the spray running on one of the doors and had to clean it all off and start again.

There are also frosted glass films in a variety of styles and levels of opaqueness that are readily available online.

Because the case will have a face frame, the sliding doors and their tracks will need to be installed prior to finishing the exterior of the case. In order to make things easier on myself, I finished the interior of the case as well as the doors before doing the final track installation.

The final step before assembly was to install the glass on the doors. I used a siliconized acrylic caulk that would provide the right amount of adhesion and flexibility to hold the glass in place. The only downside is the relatively long time to full cure. In this case it was more than 48 hours until it was safe to install the doors.

Finally, I used a piece of pegboard as a template to drill holes for shelf pins.

Put It All Together

With the doors complete, install the tracks, shelves and doors, and test the sliding function one last time. Then it’s time to cut the face frame.

For a uniform appearance, the entire face frame was cut from a single 8′ 1×4. Cut to rough length, then rip the pieces to 11/2″ wide. Cut the top and bottom to 60″ long with 45° miters on each end, and the sides to 19″ with miters as well. Measure your case before you cut these parts to size. Being off by even a bit can make matching miters tricky.

I glued the face frame pieces to the case on the top and sides and used brad nails on for the bottom. This allows me to remove that piece if I never need to remove the doors in the future. With the face frame installed, you can move onto finish sanding.

If you were careful when installing the frame, the surfaces should be nearly flush. Use caution when sanding the plywood; it doesn’t take much to sand right through the top veneer.

Apply your finish of choice to the the case and the base. I used a coat of stain and then a couple coats of water-based polyurethane to match the rest of the woodwork I’ve restored in my home. Attach the base using the pocket holes you drilled earlier. Move it into your rumpus room, add your turntable and records, and you are ready to rock!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

A modern approach to joinery yields perfect miters.

A modern approach to joinery yields perfect miters.