We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

As a professional woodworker, leaving the comfort of my shop to work on a jobsite is part of the routine. I had a portable bench, but without vises, it was only marginally useful. Having all the classic woodworking vises on a jobsite would be really sweet; and expensive. What I needed were simple, durable vises that I could build on a budget. I came up with three classic woodworking vises that can be adapted to any existing bench, using any pipe clamps.

The Face Vise

The face vise is the workhorse of any bench. It’s usually the first – and sometimes the only – vise woodworkers buy. Typically, it holds boards so their edges can be worked.

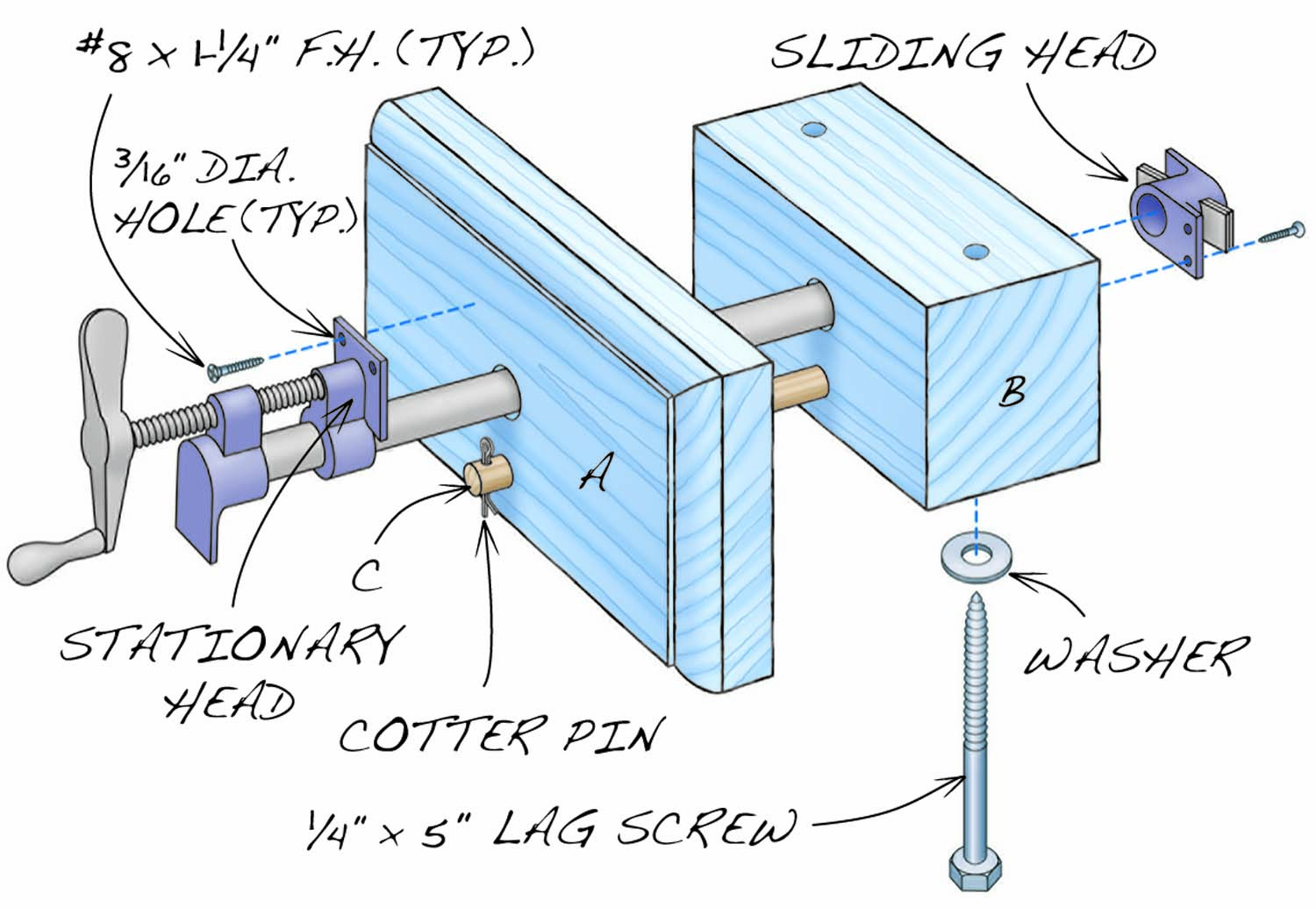

This is the simplest and most-used vise of the three. You can use whatever length pipe you like, but I find that a pipe about 14″ long is sufficient for most tasks (Fig.03).

Fig. 03. Face Vise

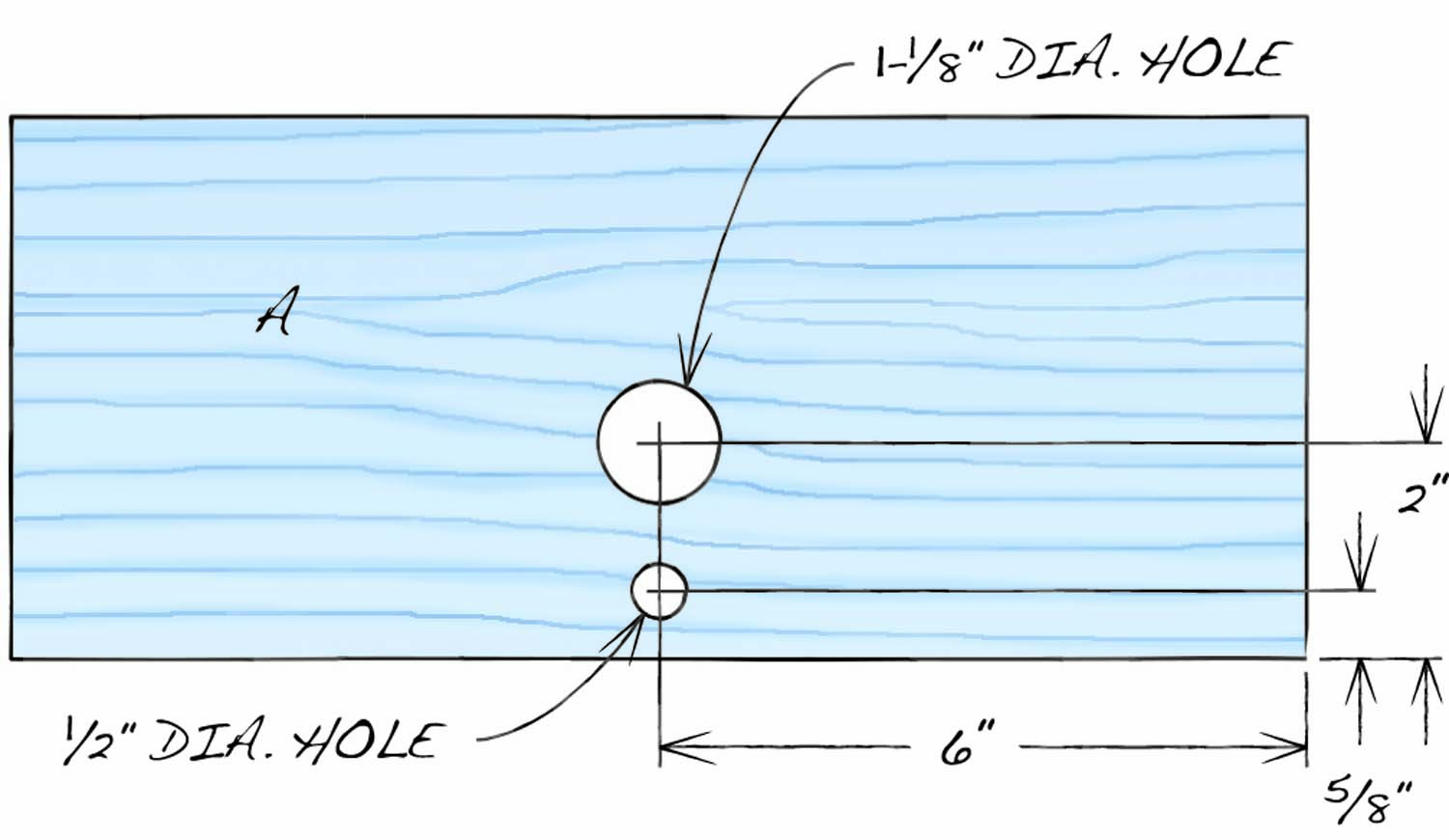

Fig. 05. Pipe and Guide Rod Locations

Cut the jaw’s pieces (A) slightly oversize, so you can true up the edges after gluing them together. Two pieces of hardwood, such as oak, make for a stiff, rugged jaw. I rounded over the jaw’s outer edges, but that’s optional.

To drill the vise’s holes, temporarily screw or nail the mounting block (B) to the jaw’s back side. Make sure the mounting block is positioned so that when the vise is installed, the jaw’s top edge will be flush with the bench’s top.

Use a drill press to drill the holes for the pipe and guide rod (C) through both the jaw and the mounting block (Fig. 05). The guide rod prevents the jaw from spinning. Next, separate the mounting block and jaw, and drill the lag screw holes in the mounting block. Using a metal cutting bit, drill holes in your clamp’s sliding head and the jaw of the stationary head.

To mount the vise to your bench, clamp the mounting block under your bench’s top, flush with the bench’s front edge, and then fasten it with lag screws.

With the clamp’s sliding head removed, insert the pipe and guide rod through the jaw and mounting block. Reinstall the sliding head, and then tighten the clamp on the two parts, with the stationary head positioned vertically, and the sliding head positioned horizontally. Along with the mounting block’s relatively short length, the sliding head’s horizontal position makes the clutch plates easy to reach. Fasten the heads to the jaw and mounting block using screws, and secure the guide rod with a cotter pin.

To adjust the vise, reach to the back of the mounting block to squeeze the clutch plates. Slide the jaw into position and tighten using the clamp’s handle.

Squeeze the pipe clamp’s clutch plates to adjust the jaw in or out to suit the size of your workpiece.

Face Vise Cutting List

| Overall Dimensions: 5″Th x 5″W x 12″L (a) | ||||

| PART | NAME | QTY | MATERIAL | Th X W X L |

| A | Jaw | 2 | oak | 3/4″ x 5″ x 12″ (b) |

| B | Mounting Block | 1 | pine | 3-1/2″ x 3-1/2″ x 7-1/2″ |

| C | Guide Rod | 1 | oak | 1/2″ x 12″ |

| Notes: | ||||

| a) Overall Dimensions do not include pipe clamp | ||||

| b) Cut pieces slightly oversize and trim to final dimension after gluing | ||||

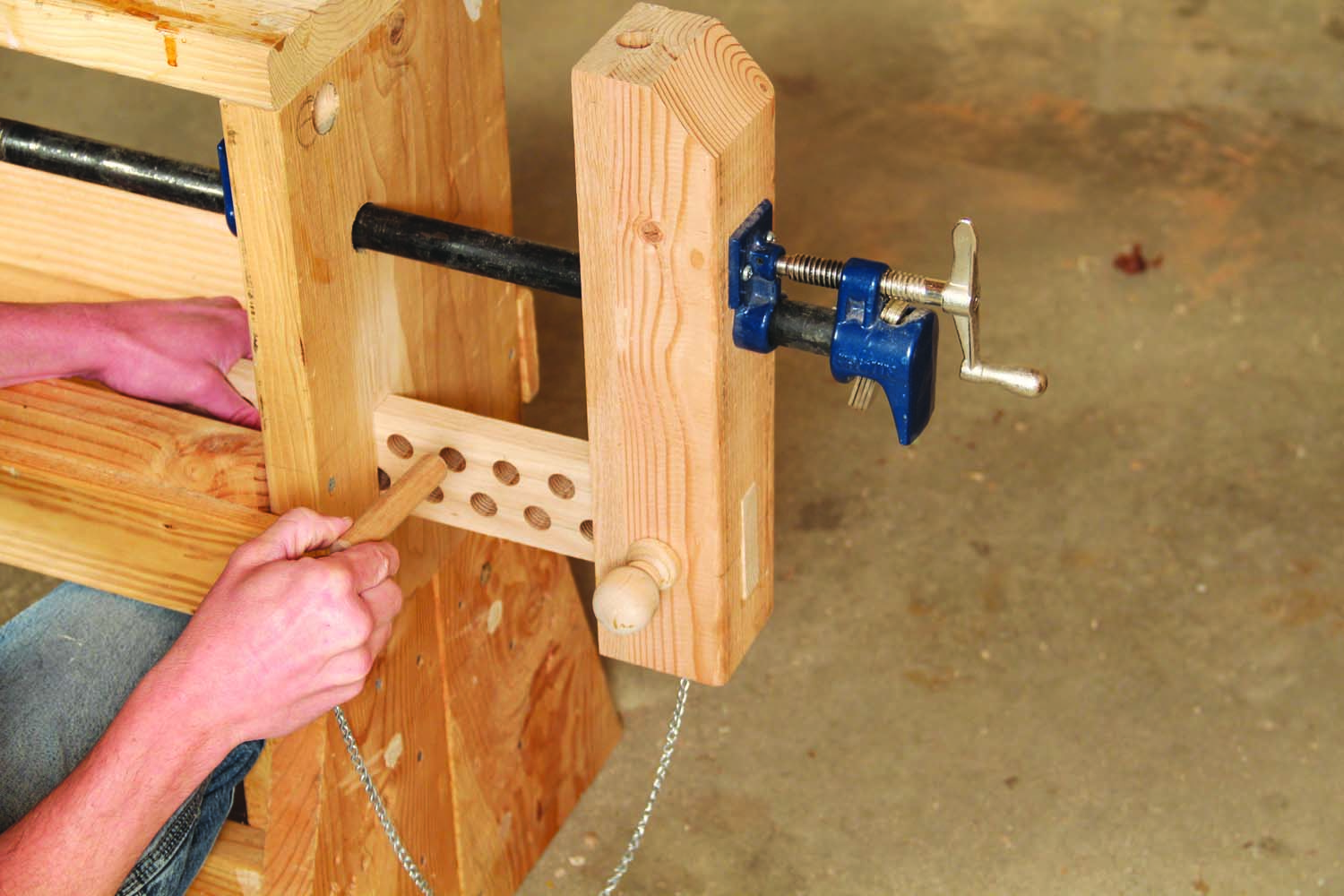

Tail Vise

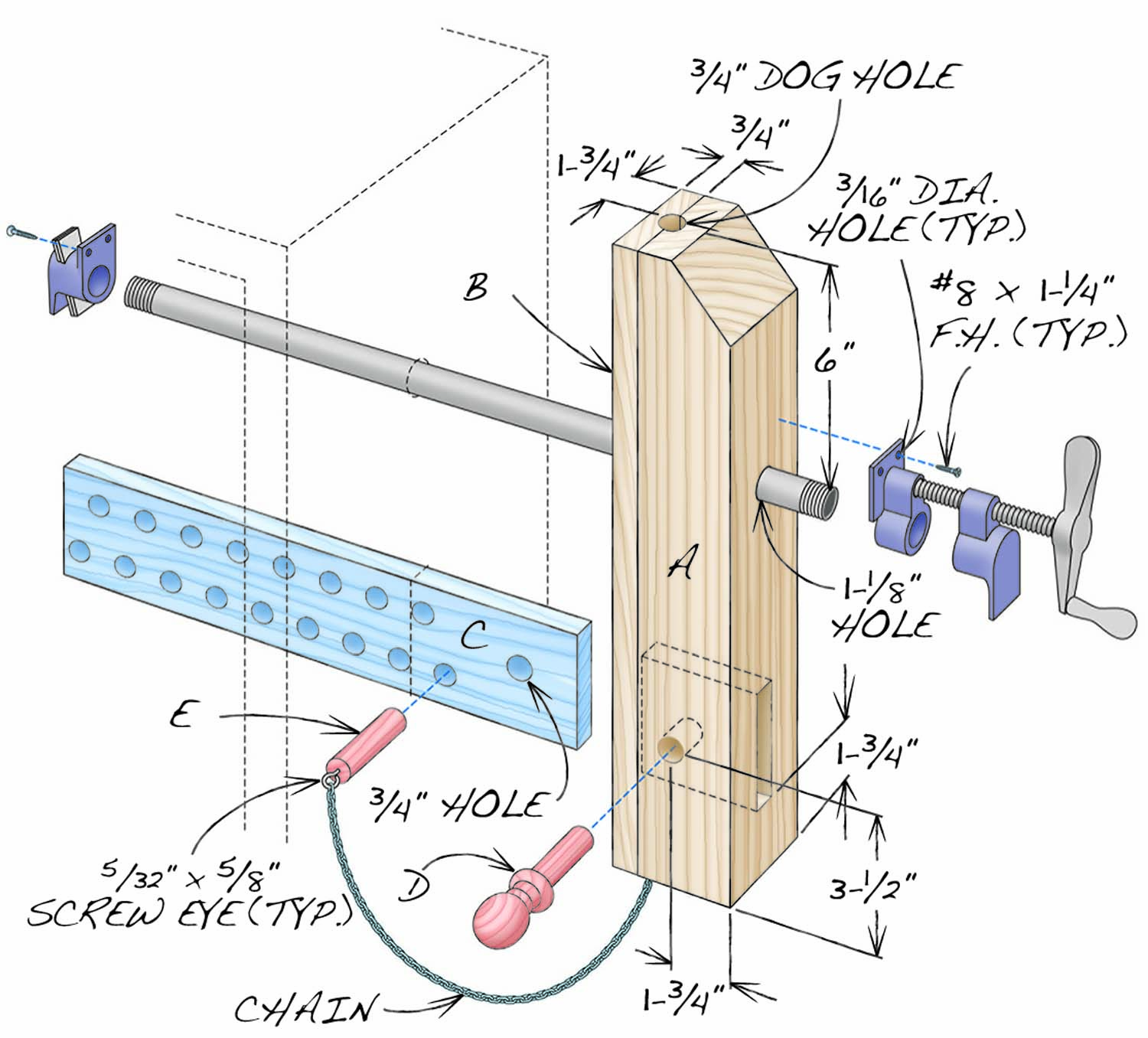

The tail vise, typically used in conjunction with bench dogs, is used for holding parts flat for face work. Mine has an adjustable guide board, similar to a leg vise. The guide board keeps the jaw from spinning and enables the vise to hold large workpieces.

Like the face vise, first glue-up the jaw (A) and faceplate (B) assembly. You could probably get by without the faceplate, but a stout wood like oak stands up to hard use much better than pine. Square up the assembly using a jointer and planer, if available. If not, a tablesaw or circular saw will do.

Mark and drill the jaw’s pipe hole using a drill press. Also, drill out the mortise for the pin board (C). A Forstner bit works best for this, because it lets you overlap the holes. Clean up the mortise’s cheeks using a chisel.

Fig. 01. Tail Vise

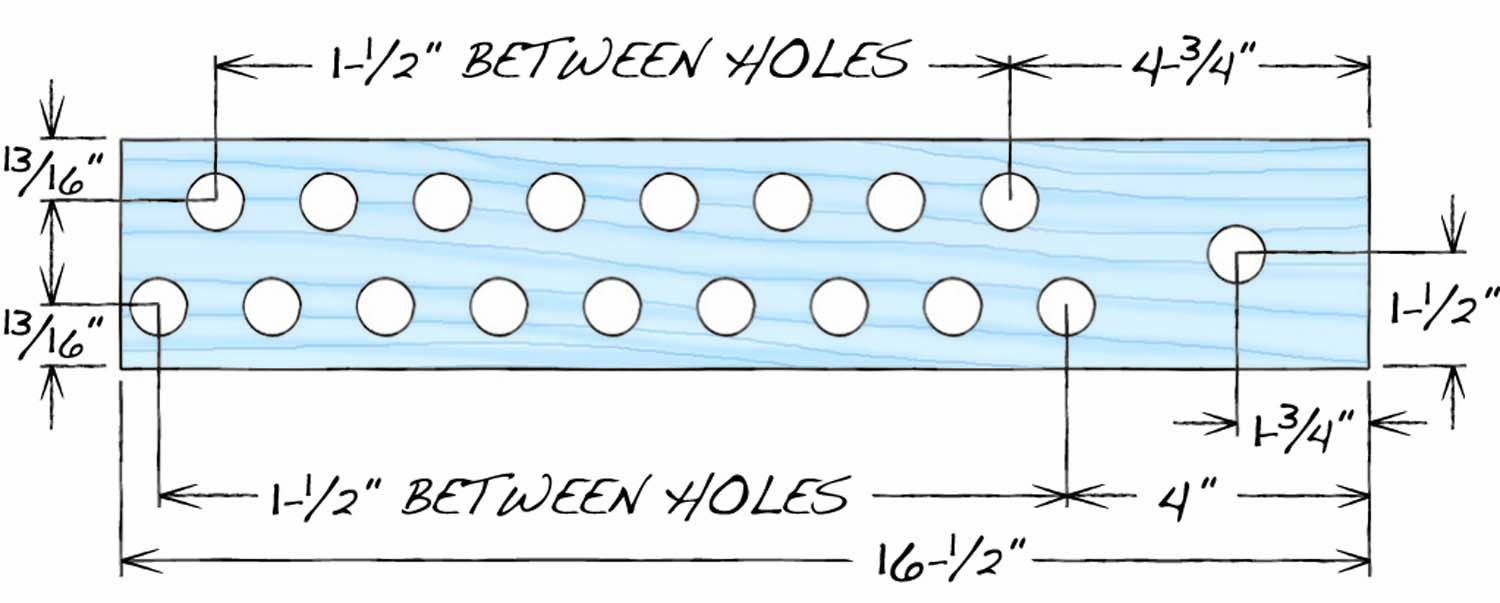

Fig. 04. Guide Board Hole Pattern

Clamp the Jaw in position to your bench’s end. Using the pipe hole and mortise you just made as guides, mark the hole and mortise on the bench’s leg.

Use a hand drill to make the pipe hole through the bench’s leg, and to excavate most of the leg’s mortise. As before, clean up the mortise using a chisel. Make sure the pin board slides freely through the leg’s mortise.

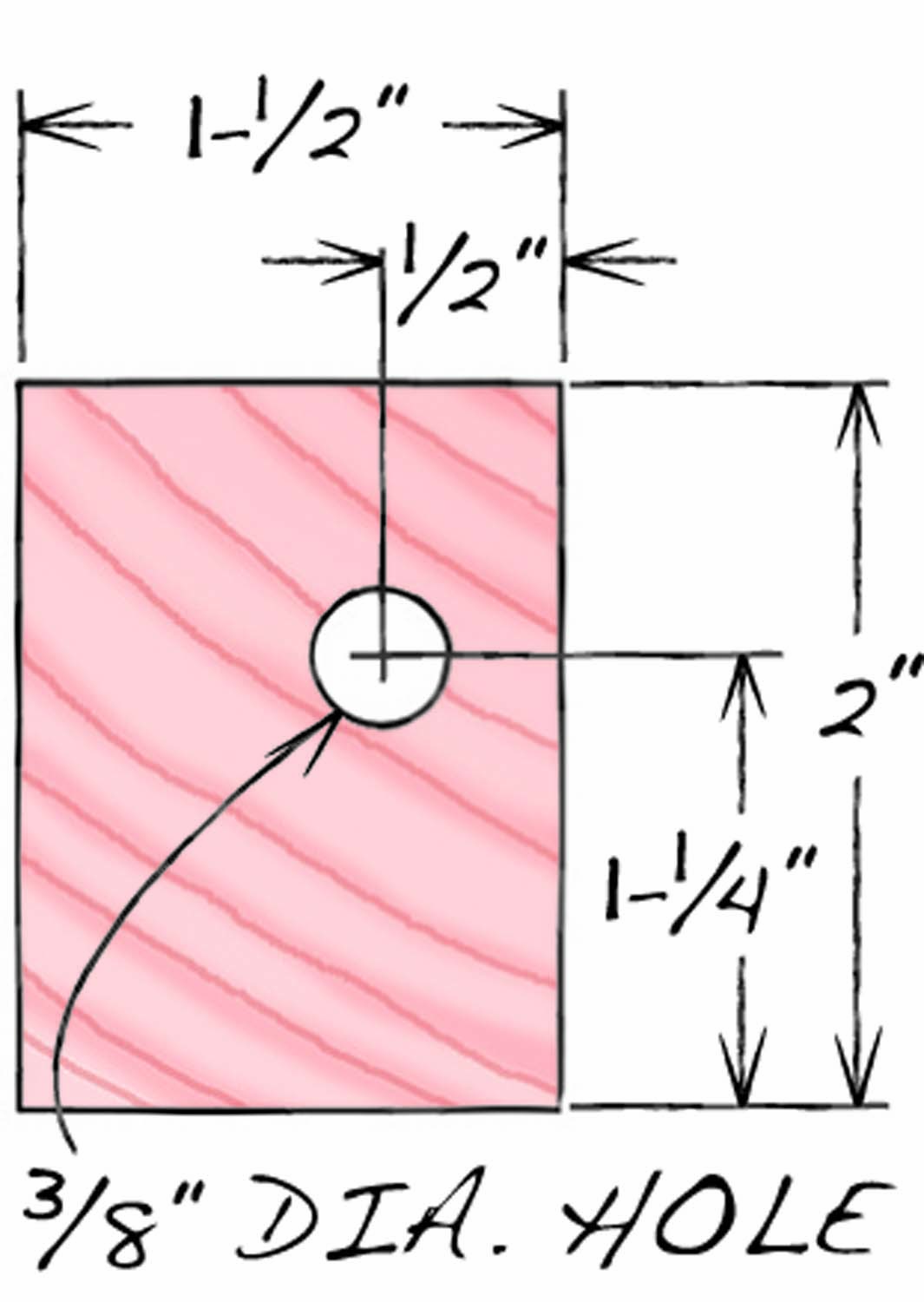

Drill the adjustment holes in the pin board (Fig. 04). Insert the pin board in the jaw’s mortise and, on the drill press, drill the hole for the knockdown pin (D). Assemble the two parts. The knockdown pin makes full disassembly easy for transport. I added a wooden knob to my pin to make it easier to remove.

Drill screw holes in the clamp heads. Insert the pipe into the jaw and slide the assembly into position on the bench. Reinstall the sliding head, tighten the clamp and install the clamp head mounting screws.

Drill the dog hole in the jaw’s top, and a series of holes in line with it on your bench’s top.

Use the adjustment pin (E) to set the vise’s opening according to your workpiece’s size. I fastened my adjustment pin to the jaw using screw eyes and a light chain, so it doesn’t get lost.

I used a 16″ pipe for this vise. Like the face vise, reach under the bench and squeeze the clutch plates to adjust the clamp.

Insert the adjustment pin in the hole that gives you the jaw opening best suited to your workpiece. Adjust the pipe clamp by squeezing the clutch plates to release their grip.

Tail Vise Cutting List

|

Overall Dimensions: 16″H x 16-1/2″W x 3-1/2″D (a) |

||||

|

PART |

NAME |

QTY |

MATERIAL |

Th X W X L |

|

A |

Jaw |

1 |

pine |

3-1/2″ x 3-1/2″ x 16″ |

|

B |

Face Plate |

1 |

oak |

3/4″ x 3-1/2″ x 16″ |

|

C |

Guide Board |

1 |

oak |

3/4″ x 3″ x 16-1/2″ |

|

D |

Knockdown Pin |

1 |

oak |

3/4″ x 6″ |

|

E |

Adjustment Pin |

1 |

oak |

3/4″ x 6″ |

|

Notes: |

||||

|

a) Overall Dimensions do not include pipe clamp. |

||||

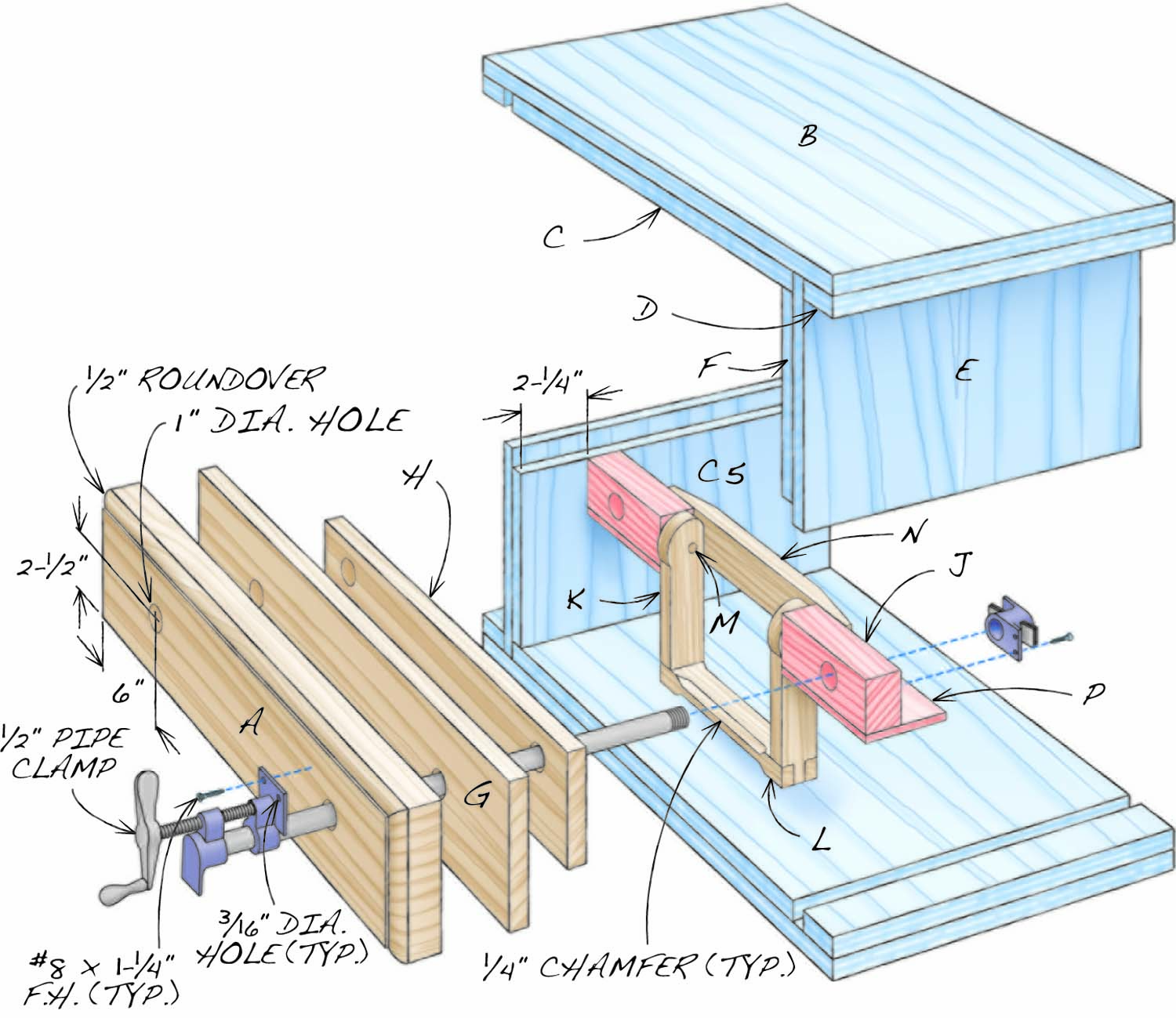

Moxon Vise

The Moxon vise is essentially a face vise with two screws. Because it clamps to your bench top, it brings your work closer to eye level; a dovetailer’s dream. My design also features a quick-release handle.

Named after its inventor, 17th century woodworker and author Joseph Moxon, this vise specializes in securely holding wide boards. Two clamps provide even pressure across the whole board without any racking. The main feature my version has that the original didn’t, is a quick-release mechanism (Fig. 02 and photo).

Another benefit of the Moxon vise is its height. Since it clamps to your bench’s top, your work is at about chest height. When you need to be close to your work, such as when cutting dovetails, this is the vise to use.

Fig. 02. Moxon Vise

Fig. 06. Guide Block End Hole

Fig. 07. Push Bar End Taper

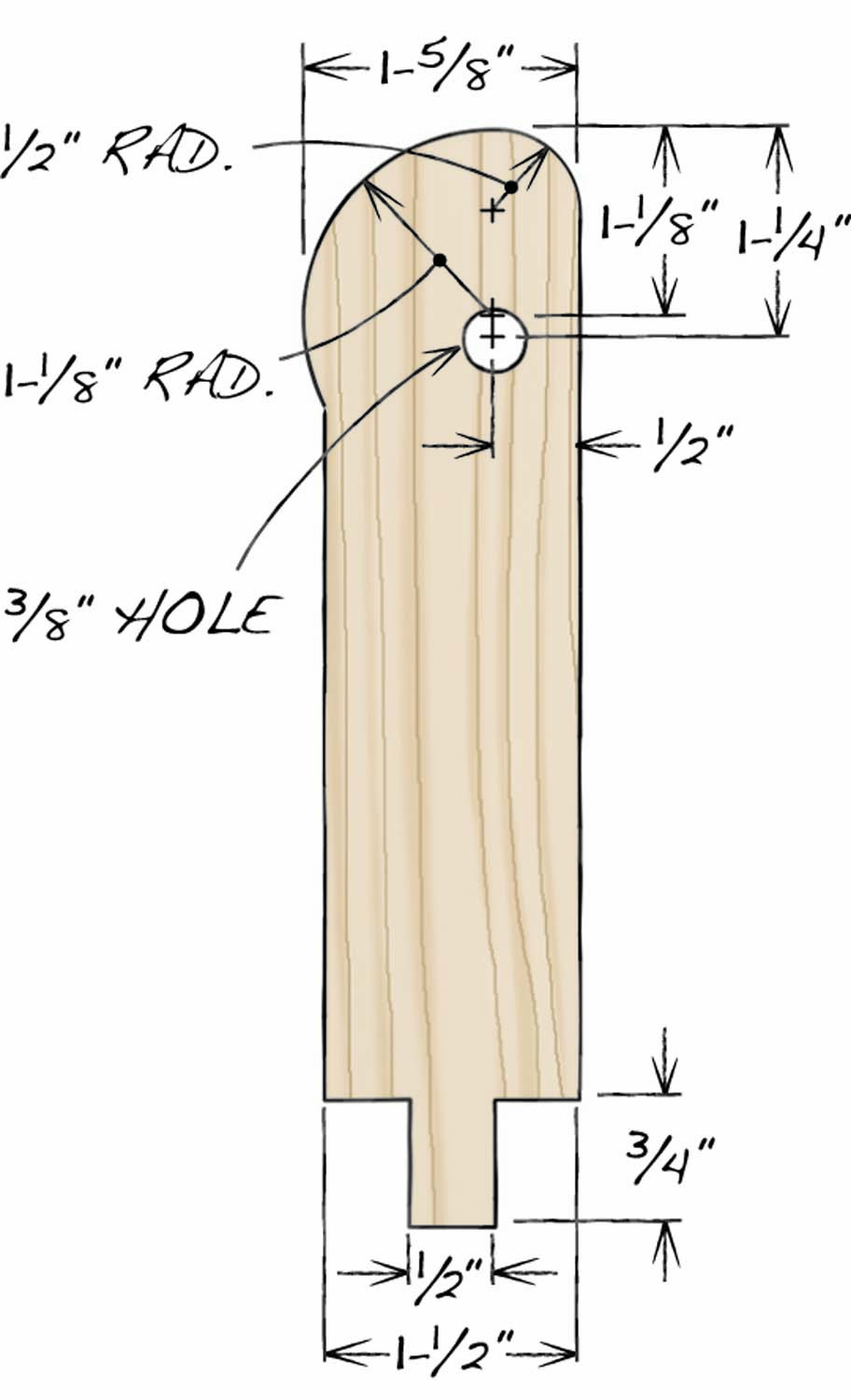

Fig. 08. Lever

Unlike the other vises, I used 1/2″ instead of 3/4″ pipe clamps. 1/2″ pipe clamps provide all the holding power I need, and I saved a little money. The pipes are 12″ long.

A good vise must be extremely stable. I made this one extra beefy, since it isn’t actually attached to a bench. Using two thicknesses of 3/4″ plywood allowed me to make deep, strong, rabbetted dado joints without having to actually cut dadoes.

To build the vise, glue up the front jaw pieces (A) and set the assembly aside. Meanwhile, assemble the top and bottom (B), including the buildup (C) and filler (D) pieces. Use a plywood offcut as a spacer to create the dadoes. Trim the front jaw to final dimension, and round over the outer edges if you wish.

Glue and screw the outer and inner sides (E & F) in place. Turn the assembly upside down and position the front jaw, rear jaw (G), rear jaw buildup (H), and guide blocks (J).

Mark and drill the front jaw holes using a drill press and then reposition the front jaw on the assembly. Slide the drill bit into the jaw’s holes to mark the hole-centers on the rear jaw. Mark and drill the rest of the jaw/guide block assembly in the same manner. Finally, drill the holes in the ends of the guide blocks (Fig.06).

Next, cut out the levers (K, Fig. 08) and handle (L). Mark the levers’ radii before drilling their holes. If you drill the holes first, you won’t have a place to position your compass for drawing the larger radius. Drill the holes in the levers, cut the bridle joints, chamfer the handle, and glue the dowels (M) in the levers.

After the glue dries, slide the guide blocks onto the dowels (do not glue) and screw the whole assembly in place.

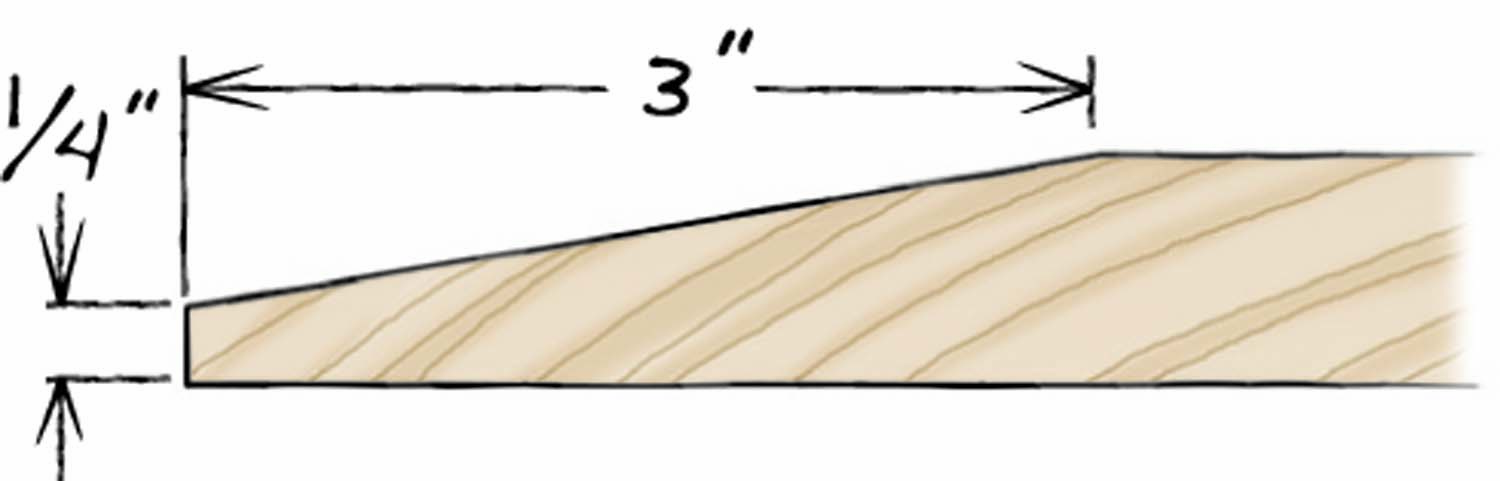

Before attaching the bottom, assemble the vise like you did the other two vises; by removing the sliding heads and inserting the pipes through the jaw assembly. Set the push bar (N, Fig. 07) in place and make sure the sliding heads are oriented properly before screwing them to the guide blocks. There should be about 1/16″ of play between the push bar ends and the clamps’ clutch plates. You might have to adjust your push bar’s ends to fit behind your clamp’s clutch plates.

Install the push bar retainers (P) and test the handle’s operation. Lastly, attach the bottom using glue and screws.

Pull the handle towards you to release the clutch plates for quick adjustment of the front jaw.

Moxon Vise Cutting List

|

Overall Dimensions: 10″H x 28″W x 16-3/4″D (a) |

||||

|

PART |

NAME |

QTY |

MATERIAL |

Th X W X L |

|

A |

Front Jaw |

2 |

oak |

3/4″ x 5″ x 28″ |

|

B |

Top & Bottom |

2 |

Baltic Birch |

3/4″ x 14-1/2″ x 28″ |

|

C |

Buildup |

2 |

Baltic Birch |

3/4″ x 14-1/2″ x 22-1/2″ |

|

D |

Filler |

4 |

Baltic Birch |

3/4″ x 2″ x 14-1/2″ |

|

E |

Outer Side |

2 |

Baltic Birch |

3/4″ x 14-1/2″ x 8-1/2″ |

|

F |

Inner Side |

2 |

Baltic Birch |

3/4″ x 14-1/2″ x 7″ |

|

G |

Rear Jaw |

1 |

oak |

3/4″ x 5″ x 28″ |

|

H |

Rear Jaw Buildup |

1 |

oak |

3/4″ x 5″ x 21″ |

|

J |

Guide Block |

2 |

pine |

1-1/2″ x 2″ x 6″ |

|

K |

Lever |

2 |

oak |

3/4″ x 1-5/8″ x 6-1/2″ (b, c) |

|

L |

Handle |

1 |

oak |

3/4″ x 1-1/2″ x 8-3/4″ (d) |

|

M |

Dowel |

2 |

oak |

3/8″ x 1-1/2″ |

|

N |

Push Bar |

1 |

oak |

3/4″ x 1-7/8″ x 14-1/4″ (e) |

|

P |

Push Bar Retainer |

2 |

Baltic Birch |

1/4″ x 3-1/2″ x 5-7/8″ |

|

Notes: |

||||

|

a) Overall dimensions do not include pipe clamps |

||||

|

b) Draw radii before drilling holes |

||||

|

c) Length includes 3/4″ long tenon |

||||

|

d) Cut 1/2″ wide x 3/4″ deep notches in both ends |

||||

|

e) Slightly round all edges |

||||

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I really like this idea, just for having some extra bench/vise space around the shop! Thanks for this great idea.

Thanks, Chad. Detailed, simple-to-build-and-afford projects like these reiterate what makes you such a valuable resource in the woodworking community.

Chad, you nailed this! Workbench vises are way out of my hobbie price range, but here is a very affordable option. The detail included in your article is excellent. I plan to make three with my son, son in law, and of coarse, one for me. thanks!