We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

It usually takes a year for a new workbench to settle down, and for me to put enough hours at it to form a half-decent opinion. Every bench has plusses and minuses.

I’ve never encountered a bench that was 100-percent perfect. And I’ve never encountered a bench that was 100-percent crap. (OK, that last part is a lie. Writers have to say things like that to appear even-handed. A lot of benches are 100-percent poo on legs.)

I’ve now had my French Oak Roubo bench in hard service for 12 months, and I have a lot to say about it, most of it good.

But let’s start with my criticisms and get those out of the way.

The Leg Vise

This leg vise has no parallel guide, but I don’t mind that. It doesn’t have leather on its jaw, but that’s not a problem. Nor does it have a “garter,” which locks the vise’s chop to the vise screw. The biggest criticism I have of the vise is the position of the vise screw itself. It’s too low for me.

When I built this bench, I stuck to the drawings of the 18th-century original in A.-J. Roubo’s “l’Art du menuisier.” The vise screw is located low – halfway between the floor and the benchtop. That position gives me an amazing 13” of clamping surface above the vise’s screw.

But it also makes me reach down a lot more than I like – even more than stooping to adjust a pin in a parallel guide.

I’ve found that 8” of clamping surface between the screw and the benchtop is plenty. And you don’t have to stoop as much. So before you blindly follow the old drawings, think this through.

Top Shrinkage

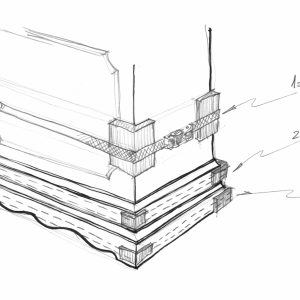

Whenever I’ve built workbenches using monolithic slabs, there is always significant shrinkage as the benchtop settles down and acclimates to the shop environment. This is only a problem if you’ve joined the legs to the benchtop with some sort of through-joint, such as a tenon or sliding dovetail.

The top shrinks but the end grain of the leg does not. So you need to plane down the end grain on occasion. I had to do this three times during the last 12 months. It’s really only an issue at the front of the workbench, but I kept the rear legs in check, too.

The good news is that this contraction stops after a few years, and then the benchtop and the legs stay in pretty much the same plane. The shrinkage of my top has greatly slowed. Since about May it has shrunk so little that I can barely feel the difference with my fingernail.

Other benches I’ve built like this reach the point where they don’t seem to move at all.

Mass

Without a doubt, this is the heaviest bench I’ve ever built; and working on it is like working on a cube made out of collapsed stars. It is a juggernaut. It’s a slab of granite that resists normal (and abnormal) woodworking activities. I never worry about the benchtop deflecting or the base scooting across the floor. It just doesn’t happen.

Simplicity

This bench has no tail vise. And its leg vise is stripped down to its bare essentials. There are almost no moving parts. That is a huge plus. Things that move will break, go out of alignment or get stuck. When that happens – and it happens to the best devices – you have to spend time mucking about with it.

I’ve repaired and adjusted vises from every major manufacturer. Their moving parts gum up with shavings and pitch. Screws and bolts loosen up. Chains sag and break. Wood moves and jams the metal mechanisms.

This bench has only one mechanical part: The vise screw. The planing stop is fit with friction. I’m sure it will loosen up someday, but that could be decades.

All the workholding on the benchtop is done with a metal planing stop, a holdfast and a notched batten. This simple setup might seem awkward when you first use it, but I quickly took to it and prefer it over other complex tail vises, which can bow the work and fail to hold thin stock effectively.

The Planing Stop

I have to call out the planing stop as one of my favorite features of the bench. Once you learn to skew your handplanes and use your hip to steady panels, you’ll be able to control wide panels against the single metal stop. I don’t mind the little marks it leaves on the end grain.

What is the Bench Missing?

The only feature I want to add to this bench is some sort of sliding deadman – also called a “board jack.” They existed on French benches that were extant before the 18th century (see Felebien), so I’d be within my rights to add one. It would make planing the long edges of wide boards much easier.

I also have yet to add a grease pot and a locking drawer, both shown on early French benches. I’ll add those in the coming year, I’m sure.

Verdict

This bench isn’t going anywhere. And that’s not just because it’s so dang heavy. This bench suits my aesthetics, my workholding needs and my desire for a simple and robust workbench. Building a bench like this is admittedly difficult. The thick material is hard to get, and the wood can be quite wet. The construction process is more involved than an English Nicholson bench, for example.

But the rewards are worth it – in my opinion. The massive French bench is still the best form of workbench I’ve ever used.

— Christopher Schwarz

Want to build one of these by hand? Check out my DVD “Build an 18th-century Workbench,” available at ShopWoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Readers – I have a question. I’m planning to build a similar, Rubo style bench but I don’t feel the need to be historically correct. I have oak slabs, quarter/riff sawn, no pith, just less than 4″ thick by 10-12″ wide (rough) to glue up for a 27″ wide top. I should be able to mill them to 3-1/2″ thick. Is it advisable to add a breadboard end to the top? I know it doesn’t match Rubo – but would it be a good idea for the structure?

It’s a beautiful bench. Re the vice, you’re probably 6 inches taller than French woodworkers of the period. When my wife and I bought an old house in France in the 80s we couldn’t believe the heights of sinks etc.

I agree on the end vise Chris. My bench has basically stopped moving but the vise block still gets sticky a couple months out of the year and it seems that I use it less and less (despite the fancy Benchcrafted hardware). I do still find it useful when traversing but have started using notched battens like you show above more and more. Regarding the deadman, I still stand firmly behind my sliding leg vise. It is the height of luxury and sits idle a lot but when needed it delivers better than anything else I have tried. And it looks cool too.

Chris, I am building a french bench using douglas fir, working from the plans in your book. Where do you get your holdfasts?

Chris,

Thanks for the update. I am especially pleased to learn that the various tail vise alternatives are not really necessary. I purchased the lumber for my bench last fall from a guy I found on Craigslist who mills his own lumber in southern Indiana. For about $150 I got enough 4″ thick ash (bench top) and 6″ poplar posts to build an 8′ long bench. For anyone who lives in a state with plenty of indigenous hardwood (IN, KY, PA, TN…), I would really recommend using Craigslist as a source for affordable lumber. Just takes some patience, but it eventually pays off.

I’ve been waiting for the time to start my build, and the funds for a proper vise. It was my intent to start with a bench hook on the front face and later retrofit either a twin screw or a leg vise at a later date. Nice to know adding a wagon vise is not mandatory to have a functional bench.

The reason you’re bending over so far is that you are a lot taller than 17th century folk. For them, the screw was probably at mid-thigh.

When the blog discusses projects, such as this bench, it would be nice to get a ballpark number as tot he cost of making the item. I know lumber prices vary across the country and by wood species; so what. Tell us what it cost you to make it and we’ll can figure what it might cost in our area and for a different wood species.

Also, when you say “French Oak Roubo bench,” do you mean a Roubo bench made out of French Oak or an Oak French Roubo bench?

Chris, Looking forward to the future updates.