We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

My dovetails are always at their best if I warm up before sawing. But I’ll be honest – when I am pressed for time I have no patience to cut an entire joint, much less prep the wood for a practice set.

So here are two things I do to get my sawing on track that don’t require extra material or significant time.

Crosscut Your Rough Stock by Hand

Even though I own some machines, I almost always crosscut my stock to rough length with a handsaw. This hand work gives a clue about what to expect with each board. Is it wet? Dry? Filled with tension and/or pitch? Mild?

But just as important is that it gets me tracking a line with my handsaw and loosens up the muscle groups I’ll use for sawing the dovetails.

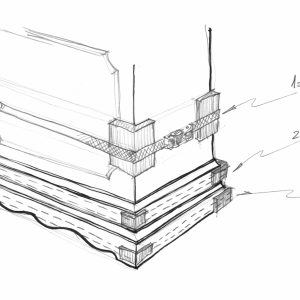

Cut Starter Kerfs in the Waste

After I lay out my tails, I make a few straight lines in the waste between the tail joints. Then I practice sawing right next to that line and confirm the cut is dead 90° to the faces of the board. I keep repeating this exercise until I get two perfect kerfs in a row that are dead 90° to the front face of my tailboard.

I also make about 10 long saw strokes in each of these “starter kerfs.” These strokes confirm that the saw teeth are sharp, the plate is free from bends and ready to go.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

You should wait 30 minutes after eating before jumping into the project…

Chris – On the subject of dovetails I figured if anyone would know it would be you … I have always wondered if the joints with honking big tails and small pins we result in a weakened pin board side of the joint. Obviously that is not the case as so many examples of them are out there: including many of your videos and the pictures above. I was wondering however if there is any information on proving them any weaker, or if a joint with more evenly sized tails and pins was any stronger.

Thanks

It’s good was to hear a veteran such as yourself doing warm up cuts. I was recently building a tool tote to use in my locker at work. I jumped right in and attempted cutting the first corner of dovetails. Not so good. My technique was poor, to say the least. Then I remembered the dovetail class at Jeff Miller’s shop here in Chicago. He had us start out cutting straight kerfs…..over and over. So, I grabbed a piece of scrap, penciled in about 30 straight marks, and had at it. The second corner turned out WAY better than the first. I guess that’s why orchestras make all that noise before the concert actually begins, no? Thanks Chris, that was a confidence builder.

Always WARM UP when attempting any physical exertion especially now that the weather has turned. Sawing, chiseling, anything that demands accuracy always prefers a measured approach to that end.