We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I travel a lot. Between trips to see my family a few hours away or taking a boat out in whichever lake is calling my name, I don’t spend many weekends at home. That’s OK with me, but all of the travel brings inevitable roadside breakdowns.

My father did his best – and still does his best – to teach me everything he can to avoid roadside disasters. Mike Russelburg is known for being over-prepared and passed that on to me (I once changed an idler pulley on the side of an interstate…yes, I had a spare belt and idler pulley).

With this knowledge comes a rather large mechanics tool kit that rests, along with other large items that I keep in the back of my Jeep. At the moment I have numerous bags, cardboard boxes and a five gallon bucket full of tools. It’s a mess.

Having just finished my Dutch tool chest build (which I will paint soon if I ever decide on a color), finally giving me one place to store all of my woodworking hand tools, the mess of my mechanic tool collection is starting to drive me crazy.

So I decided to build another tool chest. There are whispers in the office that building tool chests can be a sickness and you just want to keep building more, but I really need this one…I swear.

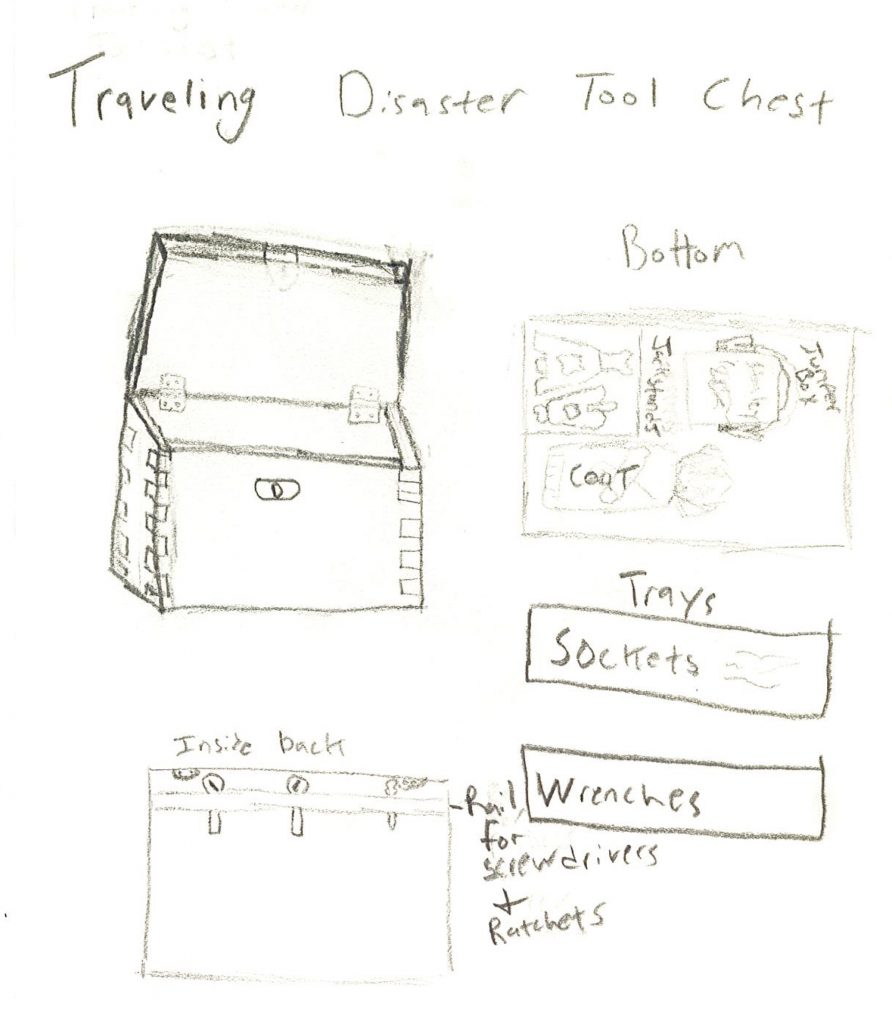

I measured the space I have available, and the size of my bigger items (yes, I keep a set of jack stands with me at all times). Then I started sketching. I am not a skilled artist, but I like to sketch things out to give myself an idea of what my needs are and how I can tend to all of those needs. My final product may look nothing like this, but it’s a good place to start.

My original design was a simple chest with box joints (shown above). The top of the chest will have two sliding trays similar to the English tool chest while the bottom will be left open for bigger items: jack stands, jumper box, winter coat, etc. I may end up dovetailing the whole thing to practice hand-cutting dovetails some more, but I’m aware that may be overkill.

Now my question: have any of our readers out there built a tool chest specifically for their mechanics tools? If so, let me know how you built it in the comments below.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Great idea for a project.

I have build tool chests, but not for roadside disasters though.

I have an old rock solid Swedish military wooden tool chest that I used for a couple of years which I stopped using. But I have some experinces from it.

An idea might be to make one or two smaller trays/boxes that could fit inside your large trays. These could work for containing all the pieces you unscrew on the road. Stuff like wheel nuts etc.

Could you by any chance make a bracket of some sort that would keep the chest fixed in the back of your jeep? I once had a van with a similar chest inside, and if I drove around a corner a bit too fast – the chest would slide around like a loose canon.

If you should be so unfortunate to get into an accident it is also nice to know that the thing won’t come flying through the car.

I stopped using the chest because it was too heavy to move around with ease. And this van had a nice flat wooden floor in the back, so I didn’t have to lift it very high up.

If I had to build something like that, I think I would build it in modules. Sturdy boxes that would fit on top of each other. Perhaps a large one at the bottom that two smaller ones could fit on top of. The modules could be kept in place by means of square strips on the lid and corresponding ones at the bottom.

A large box on the bottom with enough height to contain your jack stands, coat and jumper box. two boxes half that size to go on top for sockets + wrenches and screwdrivers etc.

The advantage of this would be more dovetailing practise for you, and you would end up with a tool chest that you could move yourself without having to empty it first.

Have fun with the project

Jonas

If this is allowed – you can see the tool chest on another forum:

http://www.vansairforce.com/community/showthread.php?t=138831

Yes I built a toolbox to hold mechanic’s tools and I keep it in the hangar with the airplane. So I have a multitude of wrenches, pliers, oil, oil filters, screwdrivers, allan wrenches, fuel strainers, spare parts, multi-drawer cabinet to hold screws, bolts, nuts, washers, AN fittings,

The design I’ve selected – and which works extremely well for me, is Chris Schwartz’ Dutch Tool Chest. I used the fall away front as a portable work bench – supported by two folding sawhorses.

I admit that I had been looking for an excuse to build the Dutch Tool chest for years, and that chest is perfect for my application.

Now I built one taller than Chris’ tallest one, and I placed it on casters – the casters were at the end of two oak boards that extended out the front and back of the chest for stability.

From your application I would think the smaller of Chris’ designs might work perfectly.