We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I found myself reviewing future projects that I want to do and on so many I’ve found some woodturning is. That’s an issue for me, I don’t own a lathe and I’ve never turned a thing. The most sensible thing to do would be make the project anyway and ask a local tuner to help me when required. That’s what we do at work and it’s always worked well. However, there is a desire within me to learn how to do it for myself. Further, I want to make my own lathe powered by my own muscle. I had a look around at options which fell into two main camps: treadle or pole.

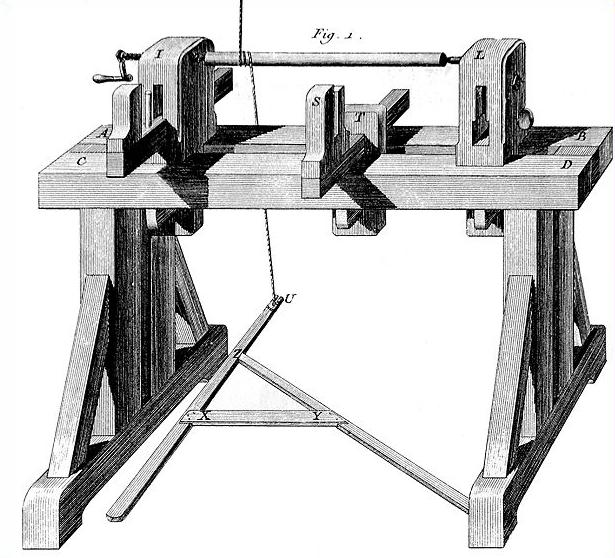

I liked the idea of a treadle, consistent speed and all that, but I was drawn more strongly to the pole lathe. The rhythm of a pole lathe and its humbleness really do appeal. But pole lathes are for green wood, right? Well they do a fine job of that but they don’t have to be confined to that medium. Enter the Roubo pole lathe. As with many of Roubo’s drawings, there is a solidity that brings a robust beauty to his designs and the lathe is no exception. Four thumb x Four thumb is the order of the day to create a very sturdy platform. (A “thumb,” according to “To Make as Perfectly as Possible” (Lost Art Press) equals 1.066 Imperial inches.)

Roubo clearly describes this as a lathe for all woodworkers and there are appliances that can be added to broaden its use beyond the format shown above. However, the above image is what’s I’ll start with and it should see me right for most of my needs.

There are two main issues concerning me, although I’m sure many more will present themselves. The first is making the ironwork for the poppets. I thought I could improvise here but thought better and discussed the project Jim Hendricks of KT Productions, who has kindly agreed to help with the metal side of things. Jim is a hugely talented person and I’d recommend following his tool-making journey, I’ve found him to be very inspiring.

The second was actually how to use the thing if it ever gets that far. Luckily for me a skilled user of the pole lathe lives in my county. Sean Hellman demonstrated turning kiln dried oak on his pole lathe via his YouTube channel. Watching his rhythm and results assured me he was the person I was looking for, and as long as I can make the lathe properly I know a day spent with him will be an investment. We’ve loosely suggested a date next year which leads me onto when.

I have an aspiration to have the lathe finished by the middle of next year and I’ll be sharing my journey, so to speak, here. This is something I would very much welcome feedback from readers. If anyone has experience of turning on or making this style of pole lathe please do leave a comment with your tips. They will be appreciated!

— Graham Haydon

Thanks to Lost Art Press for the image above, a detail from Plate 309 in “André Roubo’s The Book of Plates.”

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

A bench top bungee lathe is a quick and dirty solution for under $6 assuming you have a few clamps in your collection already.

Pipe clamp bungee lathe

Handscrew mini bungee lathe

Eitehr are easy to set up and take down and they take up little room when stored away.

I enjoy Harry Rogers YouTube posts on Pole Lathes and accounts of Bodger meets. I built a modifed version of his “Rapid Pole Lathe”. Check out his other lathe videos for other build ideas.

I did a double top rail rather than a single one. It worked OK, but I may add centers like Shannon used at Renaissance Woodworker. The best part about the rapid build is it is easily collapsed for storage and the height is very adjustable.

Graham,

I would suggest building the spring pole lathe St. Roy describes. It is an easy build, couple of days at most, inexpensive materials and it breaks down for storage or transport. It would be a good exercise in developing pole lathe skills while you work on the Roubo version. I am learning a lot on my spring pole lathe. I built mine for some of the very same reasons you are wanting to build…upcoming projects requiring turned pieces, never turned before, not yet sure I want or need a power lathe, and saved a ton of money vs buying a power lathe. When mine is not in use, I knock it down and store it in a small area next to my wood rack. Think about giving it a try.

Brent

Graham, I have spent many years pumping on a pole (or bow) lathe. There are a few things on the above illustration that I would not copy. Please let me know if I can be of any assistance. (Megan has all my contact info)

Roy Underhill’s treadle lathe—

http://www.popularwoodworking.com/woodworking-blogs/chris-schwarz-blog/foot-powered-lathe-and-scrollsaw

I like the idea of a treadle lathe, but it would take up way too much space to even consider having one. One day I would like to give turning a serious try, but it would have to be with an electric, bench-top model.

This will be interesting, Graham. Looking forward to the episodes. Of course, Megan could always go and help with the build.

Bob Easton’s lathe seems to do everything he asks of it, and more.

Al

Looking forward to working with you Graham…

Fancy a visit up to beautiful North Devon….somewhere for ALFIE to run around!!

Cheers mate

Jimi

If you change your mind about pole vs. treadle, here’s my treadle lathe.

All of the blacksmiths in my area ran for the hills long ago, so I used a few modern bits in certain areas. Yet, the rest of the lathe is from an early 19th century design.

Follow the link for 25 posts (more or less) about building a treadle lathe and some of the things I’ve done with it.

http://www.bob-easton.com/blog/category/treadle-lathe/

Graham,

Suggest you contact Shannon – http://www.renaissancewoodworker.com. He has made a couple of wooden lathes and shares his experiences on his website.