We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

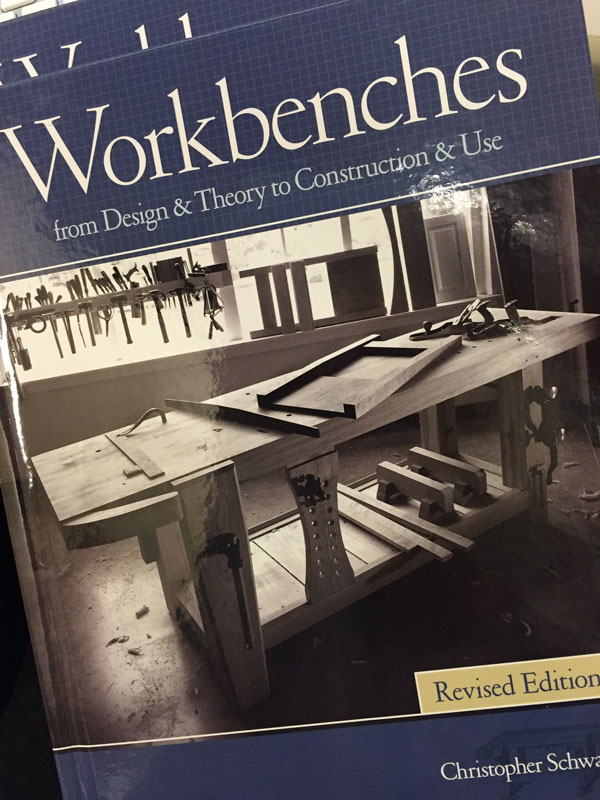

Stick around long enough and many things come full circle. When I first joined the Popular Woodworking staff lo these many years ago (OK, as of August, it was 10 years), Christopher Schwarz was working on the first edition of his first book, “Workbenches: from Design & Theory to Construction & Use.” It was published in 2007…by which time I could reliably spell rabbet. And now, he’s revised it with some new benches, more workholding and possibly an additional joke or two.

Though there are, to the best of my recollection, a dearth of rabbets in the book, Christopher let me copy edit that first book anyway – and I’m very glad he did. As a result, I knew even early on the answer to the most common question we get at the magazine: “What wood do you have access to that’s cheap and readily available?” (I trust you know the question…)

I also, however, fell in love with the Roubo bench he presented in the first book (shown on both the original and revised cover). So while I like my “Gluebo” and it functions just fine (the top does, anyway…I’ll use actual wood rather than LVL when/if I find time to rebuild the base), I find the Roubo far more attractive.

It’s the form I built for home (using the cheapest wood I could find…offcuts from a log cabin build, found on Craigslist), though the one I built is closer to the hand-tool version we presented in a 2010 issue of the magazine…and to the monolithic “Ancient Roubo” that Christopher has included in this new edition. But mine is far too small for my now much larger shop space. Time to get off my duff and build that wholly sexy “ancient” version (I need to start haunting Craigslist again for suitably cheap wood).

The other new full-size bench in this revised edition of “Workbenches” is the English knockdown bench on the cover of the current (November 2015) issue of the magazine – but with far more measured drawings and photographs. Plus, we included the “Milkman’s Workbench”– a small portable bench that can attach to any solid surface, from a kitchen counter to the tailgate of a pickup truck.

The core tenets of the book remain the same: How to build a woodworking bench that will last you a lifetime (the fundamentals rules of workbenches have, after all, remained the same for centuries, argues Christopher). In other words, if you already have the first book (and have built a lifetime workbench), you don’t really need this revised edition (unless, like me, you lust after an Ancient French behemoth). But you’ll likely (in addition to the three additional benches) find the expanded and updated section on workholding well worth your while.

As a taste of what’s in the book, after my signature I’ve included one of my favorite lists (from the first edition…you didn’t really think I was going to give away the new stuff, did you?! To get that, check out the revised edition).

The Most Common Workbench Questions (and the Answers)

When woodworkers approach the question of building a bench, they usually have a series of questions that generate quite a bit of debate among veteran craftsmen. Here are some of the most common questions, and the answers (from my experience).

1. Should I build or buy my workbench?

This gets to the heart of many questions in woodworking (buying used tools v. new tools, buying rough lumber v. surfaced stock). Whenever I face a question such as this, I answer: “What do you like to do? Work wood or fix up old tools? Spend a week at the planer or cut joints? Let your answer be your guide.” But with workbenches, my semi-Socratic method falls apart. I think you should build your workbench, even if you aren’t looking for a career in workbench building. Building a workbench teaches you a lot about woodworking, including: traditional joinery, integrating hardware into a design, balancing form and function and making assemblies that are demonstrably flat and square.

And you get to learn all this on a piece of furniture that doesn’t have to go in the living room and embarrass you if you stumble.

2. What Style of Workbench Should I Use?

Workbench purists will push you toward building a copy of a tested or classic design. I know craftsmen who have built benches that are doppelgangers of benches built in the 19th century. I say that you should use your good judgment instead. While you shouldn’t re-invent the wheel when you build a workbench, you shouldn’t be afraid to combine elements of different benches, as long as the result meets the minimum requirements for size, mass and workholding. Then I think you’ll have a fine workbench. Most workbenches (even the holy relic ones) are hybrid designs with features from other cultures. (The earliest workbench that I know of is an Egyptian rock. That one has mass in spades, but the workholding is lacking.)

3. Can I Make my Bench Mobile or Height-Adjustable?

Unless your bench is bolted down, it is already mobile. Every mobile base I’ve seen for benches has wheels that are too small, a mechanism that is too complex, a design that makes the bench unstable or a price tag that has too many zeros. I move my bench all the time and it weighs 350 pounds. Push. Shove. Done. Height-adjustable benches are for hospitals. If you need to get closer to your work to see details, buy a stool and sit down. Build your bench so it’s comfortable for common operations then adjust yourself up or down for the uncommon ones. Few people need a height-adjustable bench unless they also do dentistry or barbering there, too.

4. How High Should My Bench Be And What Wood Should I Use to Make it?

OK, now you’re getting ahead of the class. Turn the page and we’ll dissect those two questions like frogs in a high school biology class. — Christopher Schwarz (Editor’s note: Yes, I gave away one of the answers above)

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

1. Should I build or buy my workbench?

I am just finishing up my work bench, and I am one who has not held a plane or chisel in 15 years.

In this process I have learned more about tools than I thought there was to know. I have made some great friends: Craig’s list sellers, Junior College wood working teachers and students, and a few other hobby wood workers. After hunting across half the state I met a wonder old fellow just 5 miles from home (thank you Craig’s list) with two back yard saw mills (a big one and a smaller one) and 4 HUGE sheds stuffed to the gills with hard maple, walnut, madrone and other local exotics, much of it air dried for 5+years.

My wife tolerates this project, and chuckles when I show her ever more expensive better and fancier off the shelf benches as proof that I am still ‘saving money’ by building the bench.

I just wish I had done a little more wood working before I started this, I am so much better with hand tools now than when I started. So it is rough, but it is mine, and I am having a ton of fun. Chris’s The Workbench Design Book has been hugely helpful.

Hi Megan,

Is the Ancient Roubo his FORP bench? Thanks.