We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Tradition reborn. The entrance to Toshio Odate’s studio is a k¯oshi-do – traditional Japanese lattice-work panels of the same form that he made as an apprentice in the 1950s.

A new entrance to a master’s studio comes from the beginning of his career.

Downloads: PDF of this article • Koshi-do_Drawing

Editor’s note: this article originally appeared in the October 2013 issue of Popular Woodworking

The kōshi-do form (a latticed door) has existed since ancient times in Japanese temples, and has long been used to divide the exterior and interior, and sometimes as a room divider.

In the last century, the use of these lattice-style panels in contemporary housing has flourished in many parts and places. Kōshi-do evolved in style and designs immensely, especially entrance doors. Because of its origin in history and its place in ancient temple entrances, today these rolling doors represent to some extent a family’s higher social status.

Problem solving. Dimensions for the four panels are worked out with a sketch on the chalkboard.

In the early 1950s I saw kōshi-do of all sizes with lattice and white shoji paper. However, my master said he’d also seen oilpaper used. Before glass became popular in Western society, oilpaper was commonly used for exterior windows and doors. Because of the predominant style of the Western house (which had a very short roof overhang) the exterior doors and windows were exposed to rain and snow. The oilpaper let light go through while repelling some water and moisture.

Oilpaper was rarely used in Japan. I had never seen it. Because the Japanese house overhang was commonly much deeper than its Western counterpart, doors and windows were more protected from rain and snow. Also, the Japanese use the same white shoji paper for many other sliding doors, dividers and partitions. Today, however, most Japanese entrance kōshi-do have glass instead of paper.

Ripping stiles. A gagari saw is used to rip the stiles from the Alaskan cedar plank.

I believe it was in the late 1800s that common flat glass was introduced to Japan – so using glass in a Japanese house started not too long ago. The combination of the Japanese craftsman’s wisdom and ingenuity made it possible to apply glass to the traditional doors without changing or destroying the original form and structure.

Return Home

I emigrated to America in 1958 and returned to Japan for my first visit in 1969. I then saw that Japan had undergone a great face-lift during those 11 years. A big concrete highway resembling a gigantic serpent meandered through the middle of Tokyo. I did not see much subtle regimentation in the change. It was not only in Tokyo but all the way into the deep countryside. It seemed like many things had changed for the better – but also that many things changed just for the sake of change.

Smooth inside. The roku-dai kanna is used to smooth the inside faces of the stiles.

My brother had a new house, and the entrance with kōshi-do looked very nice and neat with a dark wood grain. When I advanced closer to the entrance door, I noticed to my surprise that it was not wood; the lattice was made completely out of aluminum. My brother was watching my face.“Nobody is making or using the kōshi-do with wood any longer. It would be too expensive and it’s now much easier to clean,” he said with a big smile on his face, as if telling me I was way behind modern Japanese culture. Sadness filled my body, but I do not think my brother knew why.

All at once. The lattice pieces are clamped together and marked for length.

During World War II, Japan was struck by a dreadful food shortage; city dwellers would take their belongings to exchange them for rice, potatoes and other food. Eventually, farmers became rich. Finally the war ended and soon thereafter the new government freed farmers from the feudal-like system by agrarian reform.

It was the first time in Japanese history that common farmers turned suddenly extremely rich, and now they wanted to live as rich land owners once did. The farmers began to renovate their houses with new entrance doors and exterior shoji.

Learning Experience

Two mortises, one chisel. A double-bladed chisel is used to chop the paired mortises in the stiles.

In a small village near Tokyo, my master and I were working during that period, and my first day as an apprentice was at the farmer Magobei’s house. He was the first in his village to apply these changes. Many other farmers soon followed his example. The work started at the entrance to his home, which had one large wooden door, just like a Western barn door, with two wooden wheels, about 7″ in diameter, that ran in a wide grooved track. In the right corner there was a small door.

Mortising with a double chisel.

Often one finds this door with wooden panels, however, Magobei’s had a short lattice sliding door with white shoji paper to let light through. This door is called kuguri-do or “go through-door.” First we removed the large door and reformed the large opening to a 6′ x 6′ entrance. The head of Magobei’s household then went into the storehouse and returned with several Sawara-itawari.

Sawara wood is related to the Hinoki cypress family; its heart has a strong yellow color and it has a very pleasant, sweet aroma. Itawari were planks of wood that used to be a Japanese standard, with a thickness of 1-3⁄8″ and sometimes 1-1⁄2″, and of random width and length, commonly 6′ or longer.

I helped farmer Magobei bring the planks down from the attic. There I cleaned off the dust and laid them down side by side on a straw mat. Every one of them was clean and clear, without any defect. He said he had sliced them more than 30 years ago for the entrance door. He had plenty of that material for the two kōshi-do.

Not square. The shoulder of the dividing rail is angled to match the bead below with the bevel above.

I do not remember much of the beginning of my apprenticeship; I just kept myself busy moving non-stop and made myself useful at any time, any moment. I do remember the end of the day, though; I was always exhausted and collecting mounds of plane shavings with a pleasant, sweet aroma.

Danger of Distraction

Cutting flush. The vertical shoulders of the tenon are sawn.

After Magobei’s kōshi-do, my master and I made many pairs for houses in the village and nearby small towns during the next few years. I remember one incident very clearly. It was a hot summer day. A three-day village festival was taking place and the young village boys and girls were wearing clean yukata or summer kimonos. Most of them were about my age, 16 to 17 years old. I was working with a sweat under the hot sun; honestly, I did not want to work that day. I was making 1⁄4″ x 3⁄4″ through-mortises on lattice; I had to make 69 of them.

Groove for glass. The shakuri kanna (plow plane) is used to form a narrow groove for the glass panels.

I was using my master’s 1⁄4″-mortise chisel because I did not yet have my own. It was a very short, well-used, beautiful chisel. I was mortising five pieces at the same time and the lattice pieces were quite thin; it seemed all so fragile in which to make through-mortises. I was in the middle of my work when the chisel got stuck. I pressed down with my right hand on all five lattices with my open palm, flat and wide. I grabbed the chisel-handle with my left hand tightly and yanked it out. The chisel came out and at that moment the sharp edge gouged out the middle of my forearm.

The chisel was still in my hand with a little piece of flesh on the cutting edge. Blood oozed from the fresh wound. Immediately I pinched fine sawdust to fill the cavity, then tore the bottom of my shirt and taped my wounded forearm very tightly.

No matter what, I could not waste any time. I was certain that my master knew my chisel was stuck, even though he was working 20′-30′ away from me. He detected all my movements, including how I handled tools, as if he was watching me in a clear, clean mirror. I am sure he knew that I tore my shirt and wrapped my arm with it.

I could not spend any time with my wound. If I did, he would shout at me out loud, “What are you doing!?” Then, if he discovered what happened, there would be unpleasant consequences. I tried hard to pretend as if I had bad splinters. Then I quickly proceeded to hammer the chisel with normal strength. If I eased my pounding, he would detect my condition.

Then I started hearing a strong heartbeat from the wound. I was 17 years old, and today, about 65 years later, I still remember it all clearly: the village festival, young people wearing yukata, working under a hot blazing sun, hiding the pain and wound from my master and the customer.

Old & New

Square end. One of the raised-panel hipboards is planed square on the end.

My master is gone now, but the chisel is still much alive within me. The beautiful 1⁄4″ mortise chisel with dark shiny white oak handle, a brilliant bevel and cutting edge, a gouged-out forearm wound and fresh-flowing blood. Unlike many other items or objects I have made, this kōshi-do has always remained in my heart and mind. I always thought that some day I would make kōshi-do just for myself – not for social status, but for the fulfillment of my young man’s dream.

Low bench. The hipboards are cut to size by hand.

In the 1960s I was teaching at the Brooklyn Museum Art School. One day, one of my students brought over a piece of 2″ x 4″ x 8″ light yellow soft wood with very tight grain and a beautiful scent. I asked him the name of the wood, but he said he did not know.

Looks right. The fit of the joint between the dividing rail and the stile is checked.

He gave me a little piece for a propeller of my model airplane. As I cut into the wood, a strong and pleasant fragrance filled my little studio. I fell in love with this wood immediately. Many years later at a woodworking show, one of my friends brought a plank of wood to me. “Toshio, this is yellow cedar or Alaskan cedar. Have you ever used it before?” I looked at it and smelled the beautiful scent.

On the bevel. The stiles are beveled above the dividing rail.

I told him about the episode from years ago, then he gave the plank to me. I did not know much about the wood; I had used it to make just one little propeller. But I decided that someday I’d like to make my kōshi-do with Alaskan cedar.

Practiced adjustment. The iron of the finishing plane is adjusted with light taps of a hammer.

More years passed, and I renovated my little studio that I call “Japanese studio.” There, I only use hand tools, and mostly traditional Japanese tools. My studio is a lot like a typical Japanese workshop, if perhaps a bit larger. The front opening is 6′-2″ high x 12′ wide. It was the perfect place to make use of the kōshi-do I’d long been wanting to make.

Coming through. The horizontal braces pass through mortises in the vertical lattice pieces.

The Japanese house’s usual front entrance is 6′ x 6′ with two 3′ x 6′ doors. However, I have a 12′ opening, so I decided to make four panels. When I renovated the little studio, I also made an entrance opening at the side, 6′-2″ high x 12′ wide. There I will make a different style glass door. I made traditional Japanese sliding glass door track for both entrances.

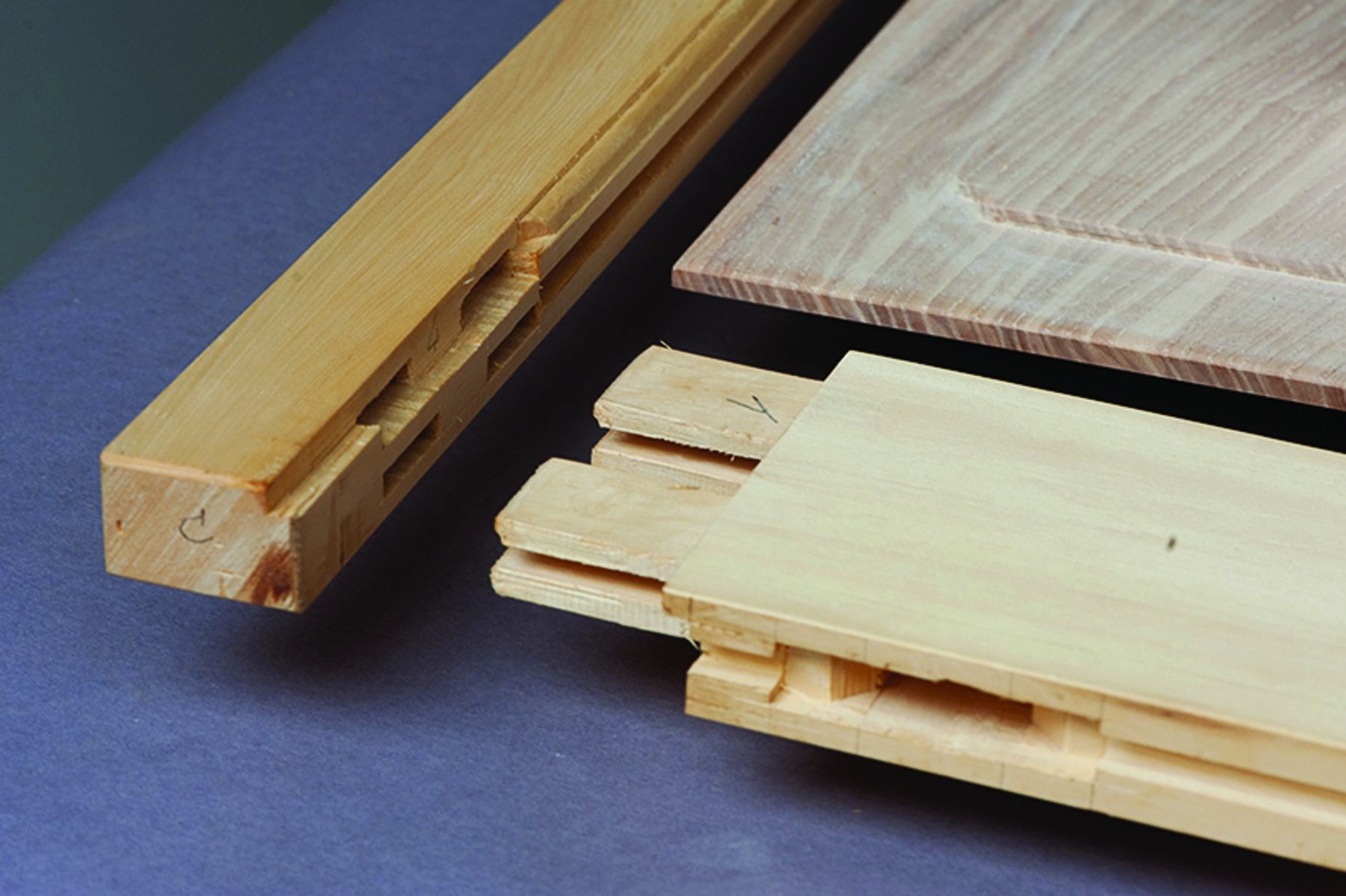

Complex corner. Note the joinery detail at the lower corner of a panel. The bottom mortise accepts a wheel that rides on a track.

Becoming ready. All the parts for one panel are arranged before assembly.

About seven or eight years ago, one of my friends told me of a nearby lumber company that carries Alaskan cedar, so I went. They had 1″- and 2″-thick planks that were 11″ wide and 16′ long. I bought both sizes, just enough for four doors. And I purchased door wheels from Japan. Now I was ready to make my dream doors and a different design glass door for the far side opening.

No turning back. Glue is applied and the panel is clamped together.

Finishing touches. A slot is cut in the bottom of the stile, allowing it to clear the rail.

Sweeping up. Take time between stages of the project to sweep up the chips and shavings.

I made the four kōshi-do with glass in 2011; the photographs show some of the process.

Now, I’ve finally fulfilled the dream begun in my apprenticeship 65 years ago. PWM

Toshio Odate finished his apprenticeship and came to the United States in 1958. Since then he has written books about Japanese tools and making shoji, taught woodworking and sculpture. He continues to work in his Connecticut studio. For step-by-step instruction on making traditional shoji, read the author’s seminal book on the subject: “Making Shoji.”

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.