We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

From top to bottom: A long 24″ aluminum straight edge (SE), a knife-edge SE, a combination square with a quality blade, an Engineers Square, and a feeler gauge.

To conclude this series of entries about lapping/flattening the soles of metal planes (read them here #1, #2, #3, #4), I wish to share some information about the precision tools I use.

The difference between Straight Edges and Rules

The primary tool I mentioned throughout this series was the straight edge. I use it to check for sole flatness before, during, and at the end of the lapping process.

We should not conflate straight edges with rulers. We use rulers to lay out lines with a pencil or to guide cutting/scoring tools over a workpiece. In contrast, straight edges are machinist tools designed to verify the straightness of a line or plane.

Most rulers are pieces of flexible steel and are not intended to be used as probing tools for the level of flatness we are interested in. A flexible stainless steel ruler will not lay true on the sole and will skew our light-sighting (for flatness) technique.

A ridged rule, such as the one that glides inside our combination square, could be used, but we should verify that it is straight and that the edge is not dented or damaged. Because these thick rulers are used to guide marking knives and owls, there is a chance that they got damaged over the years, which significantly hurts their accuracy.

This new and crisp combination square ruler is great for probing the flatness of short to medium-length planes.

Striegns Edges (SE)

Straight edges come in different accuracy grades and are my go-to tool for probing flatness.

I prefer the steel made upon the aluminum as they are more acuate and less prone to damage. However, the aluminum ones are lighter and cheaper, which are notable advantages too.

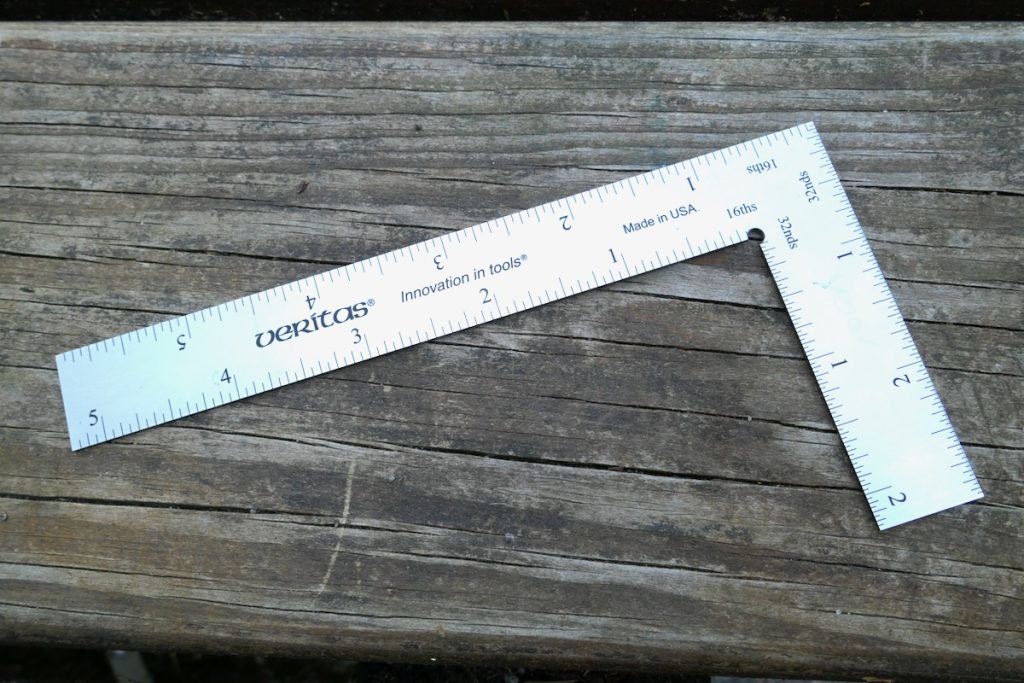

My 24″ aluminum SE was made by Veritas.

My best steel straight edge was made by Starrett. It is a rectangular section SE with a 24” blade that is long enough to probe the flatness of my longest jointer planes, such as #7 and #8. My Starrett SE is an excellent tool with an accuracy (allowed deviation from flatness per foot) of ± .0002”. However, it is an expensive tool that costs close to $100.

Steel straight edges with rectangular cross-section

Steel straightedges for woodworking can be bought from a few makers. Here are a few alternatives.

Kinex Machinist Straight Edges (DIN 874/1). A reputable Czech company makes these highly accurate straight edges. Depending on the length, they are guaranteed to be straight within 0.00047″ and 0.00082″.

The Veritas (Lee Valley) precision steel straightedges are ground flat. The allowed deviation from flattens for the 24” tool is ± 0.0010″ whereas for the 36″ it is ± 0.0015″.

iGaging 24″ Hardened Steel Bevel Edge Straight Edge. The makers guarantee the tool to be accurate within ± 0.0015 ~ 0.002”. Because they are less accurate than the Kinex tools, they are also less expensive.

Steel straight edges with knife-edge cross-section

If you can afford it, try the knife-edge SE. These tools are the easiest to use as their tapered edge is better suited to sight for light penetration between the SE and the sole.

Over the years, I got two knife-edge SE. The first one is this 6” Chinese-made unit that I purchased on eBay. The other was a 12” unit that I got on Grizzley, but unfortunately is no longer carried by the company.

If you wish to buy some good quality yet not that expansive Knife-edge SE (or/and other measuring tools), you can check the Kinex Company’s website and buy directly from Europe.

There are some promising knife-edge SE on Aliexpress stores, too, but I can’t guarantee the integrity of their actual quality as I never ordered from that site. However, at such affordable prices, I am tempted to try them.

My shorter Knife-edge SE was made in China and is 175mm long. I use it all the time, and it is convenient for probing the flatness of block planes, measuring tools, and verifying the flatness of surfaces upon which we lap.

Anodized aluminum straight edges

I bought my 24” Aluminum SE from Lee Valley and a 38” from Taylor Toolworks. I use the 38” Aluminum SE primarily for calibrating the bed of my 8” jointer.

Notice the machining marks left by the mill on the edge of this Canadian-made precision aluminum SE.

Taylor Toolworks 24” extruded and grounded aluminum straight edges are guaranteed straight to within ± 0.002″ over the entire length.

The Veritas SEs reference edge is machined flat to within ± 0.003″ over the entire length, and so is the WoodRiver by Woodcraft.

Rulers and squares that work well as SE

In the summer before my first year in high school (I went to a vocational high school where I studied, among other things, machining), I got a list of tools that I had to buy. One of them was a small Engineers Precision Square by Fisher that I still use today. This English-made square is convenient for probing the flattens of short-soled planes and checking squareness between a plane’s sides and its sole. Veritas makes an excellent 6” flat precision square that could be used to probe flattens and side to sole squareness of block planes. They also carry a larger version of this tool. And Taylor Toolworks sells a good set of four precision squares at a very affordable price.

This English-made Engineers Precision Square has been a companion of mine since 9th grade. It has served me in various ways for more than forty years.

iGaging Center Finding rulers makes a lovely, low-budget SE. The 12” and the 24” rulers are wide, grounded, and rigid enough for our purpose. These rulers are an affordable alternative to a precision SE. If you stick to a strict pencil-only policy (no marking knives), it will stay true and dings-free for many years.

Hold the ruler in one hand and pivot it toward your eyes to sight for straightness.

Before using a ruler as a SE, verify that it is not bent. Sight from one end to the other, and if you notice a deflection from a straight line, try to bend it to the opposite side until it is straight. Here I show how I sight my 12” iGaging center finding ruler for straightness.

The Veritas 6″ flat square is a good tool for probing flatness and squareness. Just make sure it has not been incidentally bent.

Feeler gauges

While the light-sighting technique can be successfully implemented with only a straight edge, there are times when I deploy my feeler gauge too. I use this bundle of progressively thinned blades if I work on a long plane and need to assess where and how much material I need to remove from the sole. Because long planes are heavy and not that easy to lift, let alone turned over – sole facing up – and then be gauged with a long and heavy SE over them, the feeler gauge technique can be beneficial.

I recommend buying a feeler gauge with removable blades (they are held together via a screw and nut) as it is easier to work with an individual blade than to negotiate the entire stack.

I like to hold my plane upside down in a vise, place my straight edge on the sole, and probe underneath the edge with my feeler gauge. I tuck the thinnest blade I can in between the SE and the sole and move it along the SE until it is wedged and can slide no more. The area/s beneath the SE that blocks the blade from traveling are the areas that I need to abrade.

You must repeat this throughout the lapping process until the thinnest blade in your feeler gauge stack can no longer be tucked underneath the SE. In my case, the thinnest blade is the 0.0015”. At that point, the sole is flat enough for my standard.

I hope this long but detailed series of blog entries has provided you with a theoretical and a practical road map to bring your plane into flatness. A plane whose sole is flat is a plane that, together with a sharp blade, can produce the best surfaces. The shaving you will create, and the quality of the wood your reformed plane will leave behind are worth the time and resources you’ll put into the lapping process.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.