We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

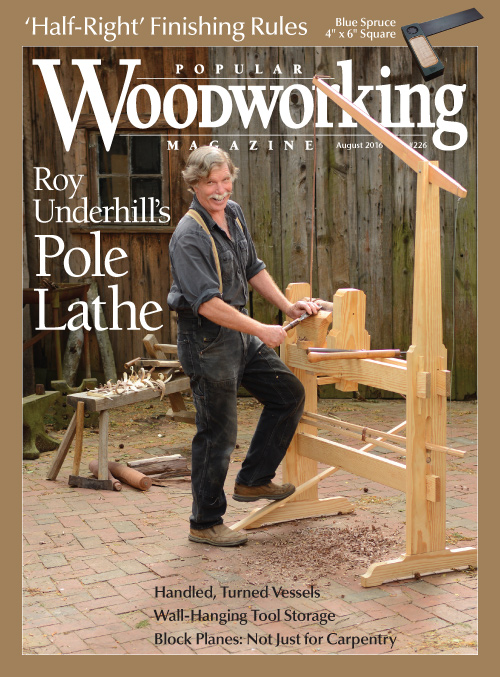

The August 2016 issue of Popular Woodworking Magazine mails to subscribers this week and features two articles on pedal-powered pole lathes. First, a hatless Roy Underhill walks you through steps to building a portable, adjustable, powerful and (considering he uses construction-grade lumber) affordable foot-powered lathe. And a few pages later, Jarrod Stone Dahl shows you how to make handled vessels using a pole lathe’s unique reciprocating motion. You can check out the online extras for these stories and more here.

Though I’ve never used a foot-powered lathe myself (or, for that matter, a plug-powered lathe – this job marks the first time I’ve ever had access to turning equipment), I was thinking about the empowerment manual operations offer in an age of automation today as I rode my bike to work. I know bike commuting sounds like an eco-commitment to sacrifice, but the hard truth is that I live 1.1 miles from our office and my motorized alternative is a gas-sipping hybrid hatchback. Aside from the fear-induced elevated pulse that crossing one busy road grants me, I can barely even claim cardio health as an impetus. Biking, though, is admittedly harder than hopping into an air-conditioned Honda, and I have to wonder if that’s not the reason I do it: Sometimes I just like doing things the hard way.

We all choose the hard way when we decide to make, rather than buy, something. You could hire someone to make a beautiful table for your home, paying a premium to commission the work and have it shipped. Cost considerations aside (and I understand there’s rarely room on the side for cost considerations – I always keep mine right up front), you technically can get the piece you want without risking a splinter. We all have our reasons for and preferred approaches to making furniture and other items from wood, but, really, we do it because we like it. We like the hard way.

Though pedal-powered woodturning may not be every woodworker’s cup of tea (or whatever’s in Underhill’s big colonial mug), you can’t deny Roy’s genuine joy working his lathe. Jarrod Stone Dahl’s passion for crafting green wood into historic and useful pieces is apparent too. You can check out Jarrod’s work at Woodspirit’s online shop, but if you want a lamhog for yourself I’m afraid you’ll have to take the hard way and follow his directives in the magazine: The store is completely sold out until new items post in late June.

Luckily, we have plenty of digital issues ready right now. And for future issues, you really should consider becoming a subscriber – it’s really easy (not everything has to be hard).

There’s plenty in the pages for non-turners too, including an in-depth look at the under-celebrated versatility of a block plane (it’s not just for carpentry!), plans for a wall-hung saw and plane till and an industry expert’s guide to making the most of a lumberyard trip. And this issue marks the debut of a new column on hardware – written by Orion Henderson of Horton Brasses, a multi-generation hardware business – that reminds us to take a breath and consider those finishing touches.

Check out the August 2016 Issue of Popular Woodworking Magazine today!

Check out the August 2016 Issue of Popular Woodworking Magazine today!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.