We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Sometimes I can have seven or eight panel glue-ups going at once. When that happens, my hands get pretty wet and slimy from all the water and wet glue. At times it makes it near impossible to get a grip on my wooden-handled clamps.

I’ve also taught many students who have a reduced grip – due to arthritis or some other malady – that prevents them from applying clamp pressure to even well-made joints.

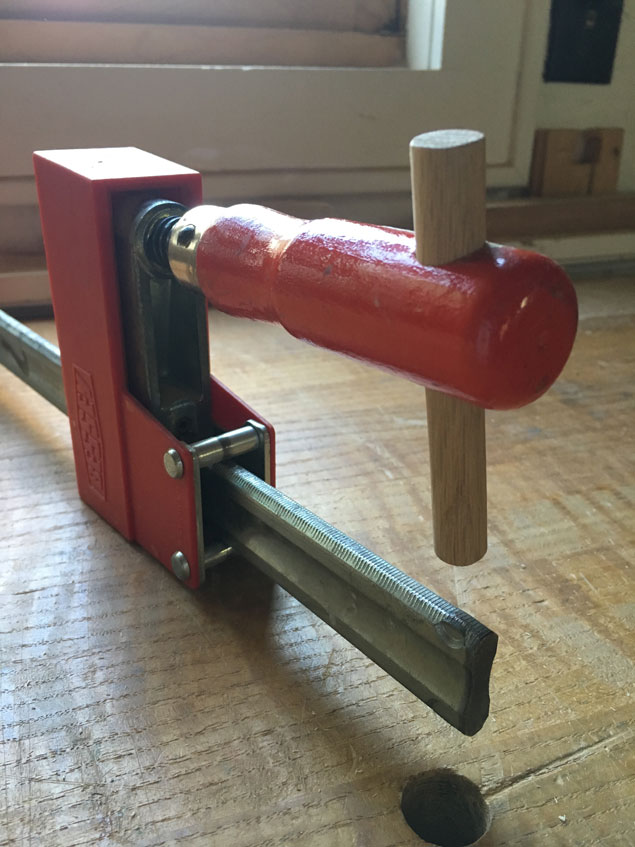

Enter the wooden tommy bar.

Modeled after the metal tommy bar found on some C-clamps, this little dowel helps immensely with glue-ups. It’s pretty obvious how to do it: I bored a 1/2”-diameter hole about 1” away from the end of the clamp’s handle. Then I took a slightly oversized dowel and shaved most of it so it would drop into the hole and tighten up before it hit the bar of the clamp (I painted the narrow end of the dowel with red marker so I’d remember which end to stick in the hole).

At glue-up time I put the dowel through the hole and apply the required pressure. Then I remove the dowel and go to the next clamp. (You could make a dowel for each clamp if you prefer).

The tommy bar also helps release the clamp pressure when the threads of the clamp occasionally become locked up.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I have wrapped all my wood handle clamps with the “Cosman” method. Tremendous improvement. Lipitor has somewhat destroyed my grip and hand strength. The tape allows me to work as normal.

I recently wrapped my Bessey Tradesman clamp handles( wood) with the tape that fuses to itself. It has a slightly rubbery feel that makes the handles easier to tighten and create more clamping pressure. However the nitrile glove trick is less expensive and would give the same result. Not so much needed on the newer Bessy parallel clamps which now come with a rubbery like handle or the Jet ones which are ribbed. On a recent job which involved cranking down a lot of parallel clamps I actually injured my wrists and thought it would be nice to have the handles designed to be able cinch them down using a pneumatic or electric impact wrench. Someone is probably working on this idea as I speak ! Your idea of the peg is definitely worth considering. Now I’m wondering if this method will work on the rubbery Bessey handles ! Thanks for sharing these ideas !

Use a disposable rubber glove, such as an old Nitrile glove. Use one to open lids that are on tight.

Regards from Perth

Derek

Rob Cosman’s trick of wrapping the handle with ridges of hockey tape to prevent slipping is also an option, although this method will give much better leverage. Rob has a you tube video on his method I believe, and I have seen it demonstrated somewhere else in a video.

Great idea Chris! The wooden handle clamps do give me a hard even with dry hands.