We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

3 Tapered Legs on the Jointer

Advanced jointer

techniques yield smooth,

consistent tapers.

By Seth Keller

After I learned to cut tapered legs on the jointer,

I never went back to my bandsaw or tablesaw.

Legs cut on the jointer take less time and, best

of all, require a whole lot less sanding. This is

especially true with the spade-foot design in which the jointer’s

cutterhead automatically creates the sweep above the

spade foot. The same leg cut on a bandsaw would require

hand shaping and sanding to finish the profile.

All three legs shown here are made from 1-3/4 x 1-3/4 x

29 in. stock. The first leg I’ll explain how to make is the

familiar long taper found in many Shaker designs. Often,

this leg has the taper on only two adjoining faces. The second

leg has a short taper used on cabinets with legs and on

some stylized modern pieces. The last profile, a tapered leg

with a spade foot, builds on the techniques used in making

the first two legs. This remarkable shape is both elegant and

refined. It hints at Hepplewhite and Sheraton furniture

designs from the eighteenth century and can make a piece

distinctive and stylish even today.

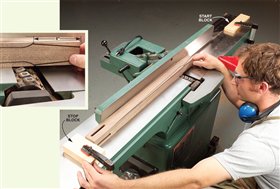

The technique involves dropping a leg down on a running

jointer. That may seem a bit scary at first, but stop and start

blocks make the procedure safer than with most tablesaw

taper jigs I’ve used and more accurate than for any taper I’ve

done on a bandsaw.

It is a good idea to use a test leg to set up the cuts. As always,

mill the mortises before you shape the legs. Finally, make sure

your knives are sharp and your jointer is well-tuned.

1. Long taper1. Lay out the desired taper on all four sides of the leg. 2. Position the start block on the infeed table using 3. Set your jointer’s depth of cut to 1/8 in. With push 4. Complete the cut (Photo 3). Make three or four 5. Rotate the leg 90 degrees into the fence and cut 6. After all of your legs are tapered, you’ll likely see 7. A little sanding completes the leg. |

Click any image to view a larger version. 1. To set the start block, position the leg blank on the jointer 2. Start the taper cut by slowly lowering the leg onto 3. Create the taper in several passes. Feed the leg slowly 4. Complete each taper with a shallow cleanup pass |

2. Short taper1. Lay out the taper on the leg blank. Construct a 2. With the jointer turned off, set the cutting depth to 3. Turn the jointer on and make the cut, keeping 4. Sand the leg smooth. |

A simple sled angles the leg on the jointer to create the short taper. Position the leg on the sled |

3. Spade foot and taper1. Lay out the taper and spade foot on the leg. 2. Clamp a stop block on the outfeed table (Photo 3. Turn on the jointer. With its foot against the 4. To create the spade foot, remove the start and All that’s left is a bit of hand-sanding to smooth the |

1. The spade foot starts 2. Push the leg over the cutterhead. Slow and 3. Create the foot using the same sled technique you |

|

This story originally appeared in American Woodworker January 2007, issue #126. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.