We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

While I think a tool chest is the best place to store your tools, the chest can also become a rusty tomb if you aren’t careful.

Woodworking shops can be nasty places. I’ve worked in unheated garages, damp basements, former warehouses and sheds with dirt floors. And when I inspect old tool chests, it’s common to find rot in places. Once the bottom gets soaked, it acts like an ever-moist sponge in a greenhouse. Your tools are pretty much doomed.

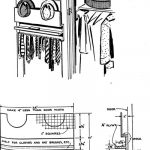

Well-made chests are usually elevated on narrow strips of wood, which I call “rot strips.” These act as an early warning system and confine the moisture to a small area. When these strips get punky, you replace them with new ones.

How you make the rot strips depends on where your chest will go. My current chest is elevated 3” off the floor on casters. I still have rot strips on the bottom, but they are made of pine, nailed in and are surrounded by the skirt of the chest. Unless, my shop is flooded, it’s unlikely they will ever get wet.

But this week I’m building a tool chest for a customer and its new home is uncertain. It won’t be on casters, and it could occasionally be in a wet place. So my rot strips are different.

For these 1/2”-thick rot strips I used white oak, which is a tough, rot-resistant wood. I chose it for its toughness more than its rot-resistance. I’d actually prefer the strips to fall off if they got wet.

But this chest will probably get moved a lot. So white oak it is.

I beveled the two long edges and the ends to make the chest easier to move. On old chests I’ve found that the ones that are easier to move have rot strips that are rounded or beveled – this prevents the rot strips from snagging on a nail or even a threshold of a door. Chests like this are almost as easy to move as those on casters.

I’m also going to screw these strips onto the chest with unplated steel screws. The screws are less likely to bend, so the rot strips won’t get yanked off the bottom of the chest when it’s moved. Also, the screws will be prone to rust. So if they rust out because of exposure to moisture, you’ll know that your rot strips are getting wet and it’s time to replace the rot strips and find a drier shop.

Little details like this can prevent your tools from becoming iron oxide – though nothing protects them as much as using them regularly and wiping them down with an oily rag before you put them back in the chest.

— Christopher Schwarz

I’ve written a lot about tool chests here on the blog. You can read my other entries here. I’ve also written a book called “The Anarchist’s Tool Chest” that discusses tool chest design and how to pick the right set of tools that go in it.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Following the same logic, would it make sense to put sacrificial rot strips on the bottom of workbench legs? Perhaps a couple of inches of white oak or cypress as a foot? In most cases your workbench is sitting right next to the tool chest, so it would be exposed to the same conditions. I am in the process of building my bench and wondering if this would be a good step to increase the lifetime of the bench.

Justin

Some years ago, I worked with a British master yacht joiner (a master in the very old-fashioned sense) who kept most of his hand tools in a chest.

He had drain holes in the bottom as well as “rot strips” (which he called “lifts”). But, according to him, the real protection of tools over time is to rub them down – not with an “oily rag” but with a rag saturated with lanolin. A very thin coat of lanolin on the surface of each tool affords much greater protection, he says, than oils can give.

He said that shore-side joiners used suet or mutton tallow, but on the water, lanolin is far more water proof and salt tolerant.

I have my antique chest up on a furniture dolly. One of those low to the ground rectangular things with 4 wheels (from, gasp, Harbour fieght) Didn’t require any modification to the chest keeps it off the floor and on wheels.

As I have been absorbing the ATC and reflected on your your choice of cypress as bottom boards I thought why not give the outside a coat of WEST about 1/3 of the hgt. Not sure how that would affect seasonal movement.

Assuming water levels shallower than the thickness of the rot strips, I have to wonder if it would be practical to isolate the strips from the main body? If you are able to prevent wicking to the box by placing a barrier strip between the strip and the box, something such as 1/16″ vinyl, or linoleum, aluminum, I would think that this would isolate the wetness, and it would not really show to the eye.

Just a thought.

Lee (the saw guy)

Whenever I build anything out of wood that may or will be exposed to water, I make sure to seal the endgrain with an acrylic waterproofing sealer, slightly dilute tung oil, or BLO. Pour the sealer into a mixing cup or can and stand the end grain up, on end, in the solution, until the endgrain has wicked up as much solution as it can.

I have found this extends the life of doors, wooden window screens, ladders, whatever, by a factor of at least ten.

BTW, got a recommendation for casters on the Anarchist’s Tool Chest?