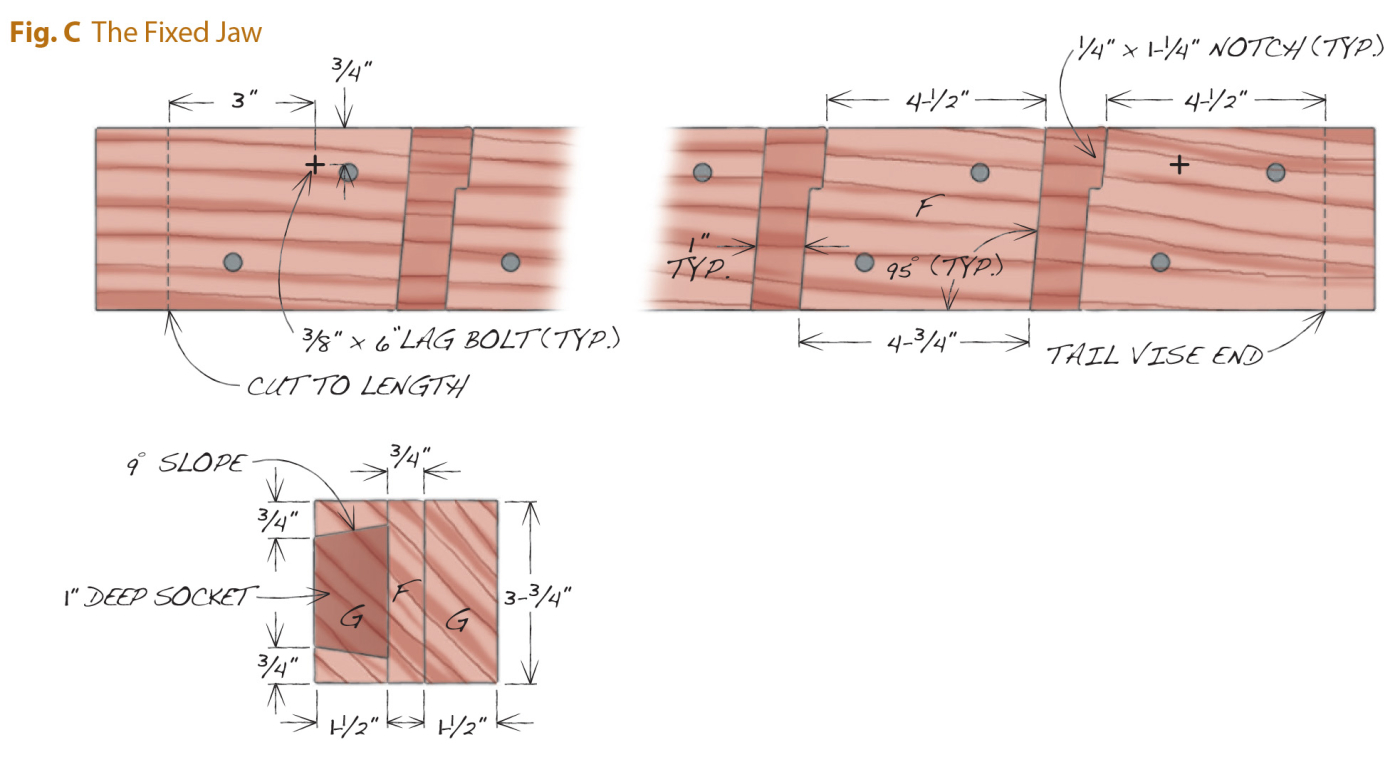

We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Upgrade your bench and your woodworking by adding a classic vise.

You can do without a tail vise. But you can do much more with one. That’s why woodworkers have depended on tail vises for over 400 years. A tail vise can be used to clamp boards of all sizes horizontally or vertically for planing, sanding, carving, routing, gluing, etc. Modern versions employ metal screws and guide plates, but I prefer the traditional all-wood construction shown here, partially because it’s beautiful in both form and function, and partially because you don’t have to buy any vise hardware, only a thread box and tap, which can be used over and over.

Clamp horizontally. Clamp long and short boards on top of the bench, fully supported for planing.

This vise can be mounted on virtually any workbench, although modifying the base is almost sure to be a part of the project. A bench with a trestle-style base and a top that extends beyond it at the front and on the right side, as shown here, is ideal.

Clamp for work. Hold furniture parts for chopping, carving and routing. Hold jigs and fixtures, too.

Like any clamping device, a tail vise has two main components, a fixed jaw and an adjustable jaw. Both jaws accept bench dogs, so that in addition to clamping between the jaws, a tail vise can also clamp above them. This dual capability is the key to a tail vise’s versatility.

Clamp vertically. Clamp freely between the jaws. Unlike a face vise, there are no screws or guide bars to get in the way.

The fixed jaw is a laminated beam that’s glued and screwed to the front of the bench top and reinforced by a solid beam—called an end cap—that’s attached to the end of the top. The adjustable jaw opposes the fixed jaw. It’s a complex rectangular frame that mounts against and underneath the bench top, supported and guided by another end cap. The screw that operates this jaw threads through the same end cap.

Additional Reading: Check out this fantastic moxon vise project.

In our store: Purchase this book on traditional jigs & fixtures for hand tools

Watch: Build a sturdy workbench to mount this tail vise on.

Cutlist and Diagrams

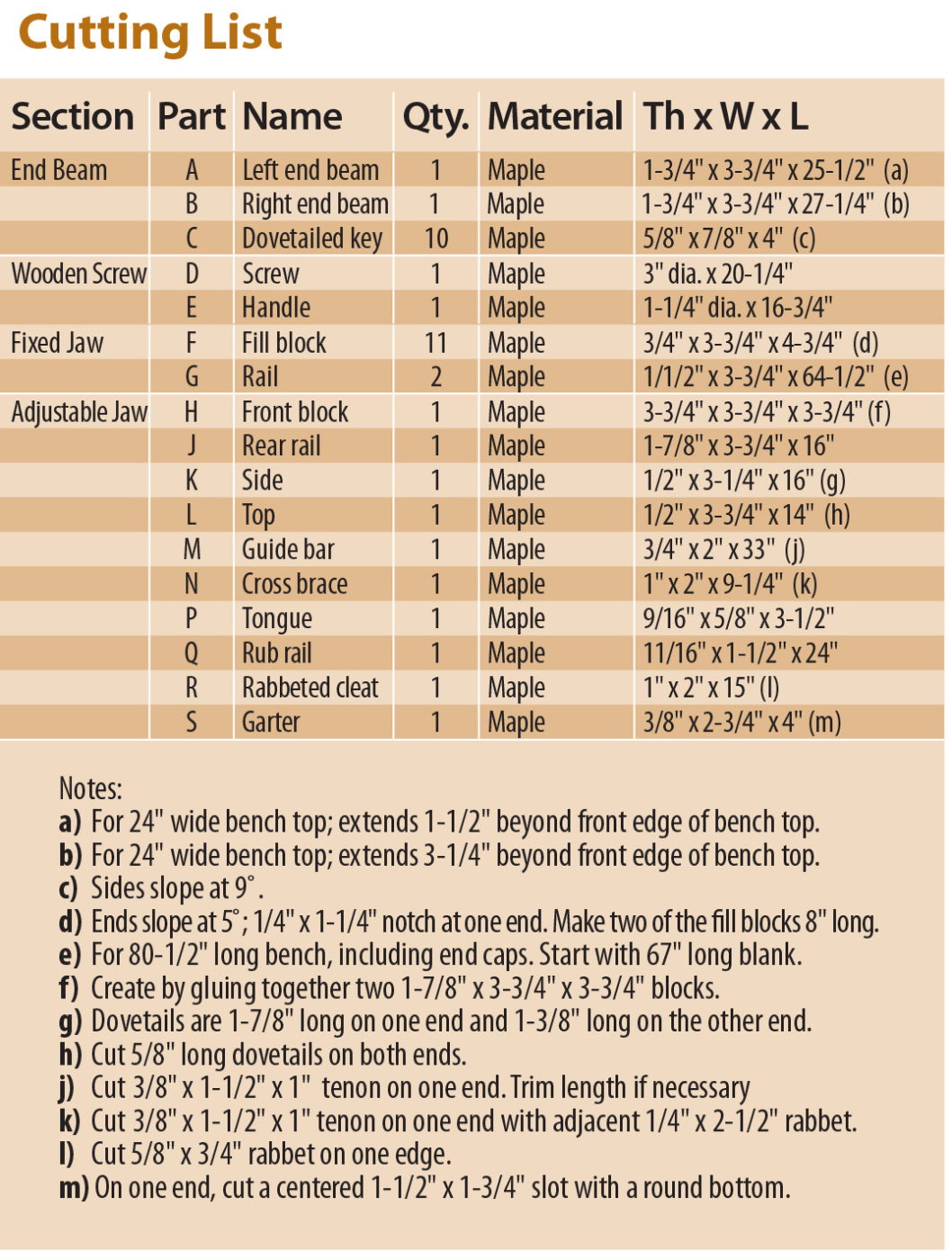

Start with the end caps

The end caps anchor both jaws. They also keep the bench top flat. Start with two 1-3/4″ x 3-3/4″ maple blanks that are about 6″ longer than the width of the bench top. Use the tablesaw to cut a 7/8″ wide dovetail-shaped groove on the inside face of each end cap blank, starting 5/8″ from the top edge. Tilt the blade 9˚ to cut the angled shoulders. Then install a dado set to remove the waste. Clean up each channel and drill a single countersunk shank hole for a 3/8″ x 6″ lag bolt.

The end caps must be wide at the front to support the vise jaws, but they can be narrower at the back. Cut notches on the bandsaw or by making a series of stopped cuts on the jointer.

Dovetail-shaped keys (C, Fig. A) simultaneously hold each end cap tightly against the bench top, yet still allow seasonal movement. Make two key blanks on the tablesaw with the blade tilted 9˚ and set at 1″ height. Stand a 1″ x 4″ x 24″ blank on its edge and make two passes, resetting the fence between passes to determine the key’s width. Make a third pass with the blank on its side to cut out each key. Each key blank should tightly fit the end cap’s grooves, but slide without binding. It must also sit flush with or slightly below the cap’s face.

1. Start by installing end caps on both ends of the bench. They mount on dovetailed keys that are located using a jig made from an offcut.

Cut the blanks into 4″ long keys and use a jig to screw them to the bench top (Photo 1). The jig is simply a 2″ wide offcut from one of the end beams with a fence glued on top. Slide a key into the jig and position the jig on the bench. Drill a countersunk pilot hole through one end of the key and into the end of the bench. Install a screw. Repeat the process on the other end of the key. Then remove the jig. Space the keys about an inch apart, starting 1″ from the front of the bench top.

1B.

Finish and install the end caps one at a time. The left end cap (A) extends 1-1/2″ beyond the bench top and is dovetailed to the fixed jaw. Lay out and cut this lapped dovetail on the front of the cap. Rub paraffin in the cap’s dovetailed groove and then drive it onto the keys and into position on the bench top. Install the lag bolt and finish by trimming the back end flush.

2. The right end cap contains a threaded hole for the vise’s wooden screw. A woodthreading kit contains a tap to thread this hole and a thread box to cut threads on the screw.

The right end cap (B) extends 3-1/4″ beyond the bench top to support the sliding jaw and anchor the wooden screw. Use one of the keys to fill the front end of the dovetailed groove. Mark the center point of the screw and drill a 1-1/4″ dia. pilot hole. Lay out and cut the notch at the front and the mortise. The notch allows the adjustable jaw to ride over the end cap as it’s opened and closed. Similarly, the mortise accommodates the adjustable jaw’s guide bar, which slides under the bench top. Make this mortise large enough for the guide bar to freely slide through. Use a 1-1/2″ dia. threaded tap to cut the threads in the bench-screw pilot hole (Photo 2). Then follow the procedure described earlier to install this end cap.

The wooden screw

3. Turn the wooden screw. Finish by cutting a groove for the garter in the collar. The garter locks the screw in the vise’s adjustable jaw, but allows it to revolve freely.

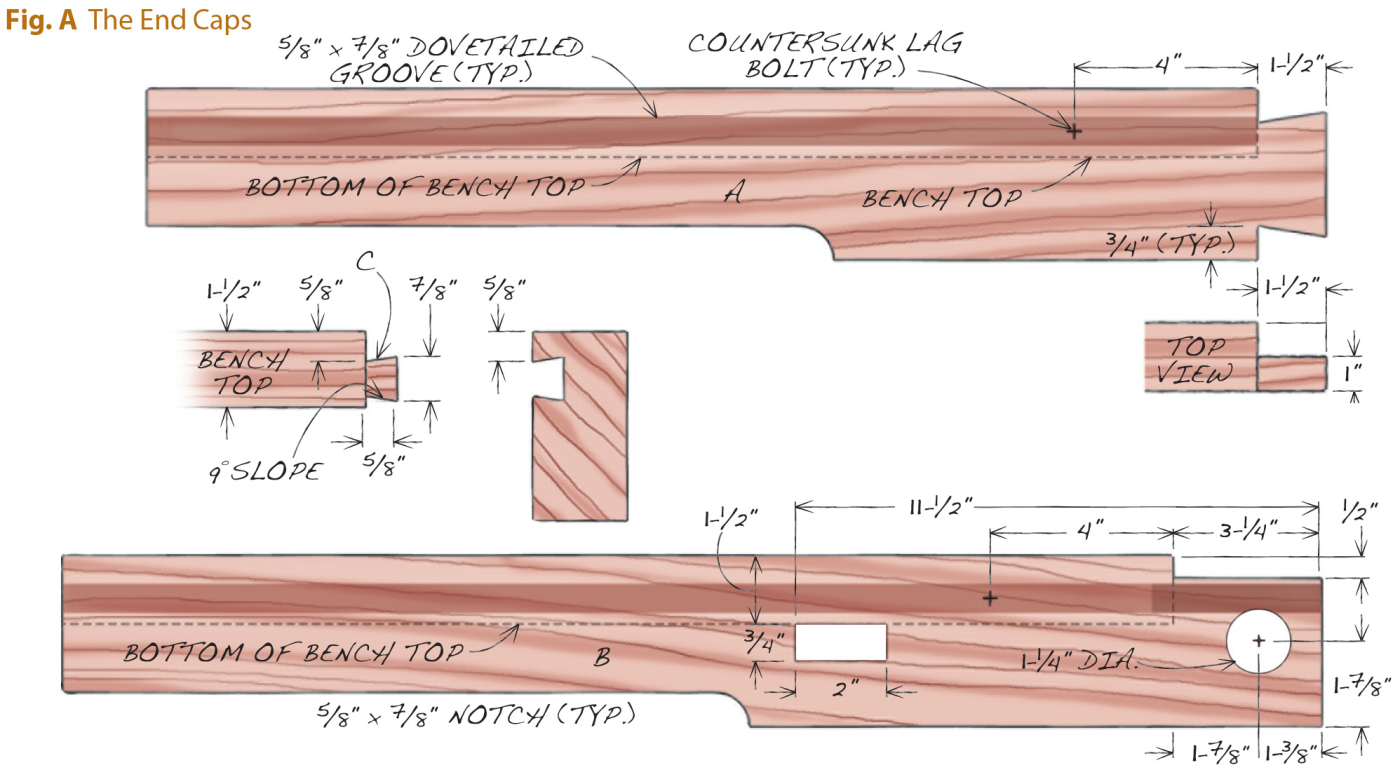

Make the screw (D, Fig. B) from a 24″ long maple blank turned to a 3″ dia. cylinder (Photo 3). Lay out and turn the head and the 2″ dia. x 1-3/4″ collar. Turn the shaft to 1-15/32″ dia. and finish by cutting a 1/4″ deep groove in the collar for the garter.

4. Use the thread box to thread the shaft of the wooden screw all the way to the collar. These threads fit the threaded hole in the end cap.

Clamp the turned screw in a vise (the vise on your other workbench) and use a 1-1/2″ thread box to cut the threads into the shaft (Photo 4). Turning the shaft to just under 1-1/2″ dia. keeps the shaft from binding in the thread box as the threads are cut.

Use a V-block and a drill press with a fence to drill a centered 7/8″ dia. hole in the head of the screw for the handle (E). Turn the handle from an 18″ long maple blank turned to a 1-1/4″ dia. Turn the shaft to 3/4″ dia., with a knob on each end. On one end, next to the knob, turn the shaft down to a 9/16″ dia. tenon. Remove the handle from the lathe and cut off the knob that’s next to the tenon. Clamp this knob in a hand screw and drill a 9/16″ dia. stopped hole for the tenon. Slide the shaft of the handle through the hole in the head of the screw and then glue on the knob.

The fixed jaw

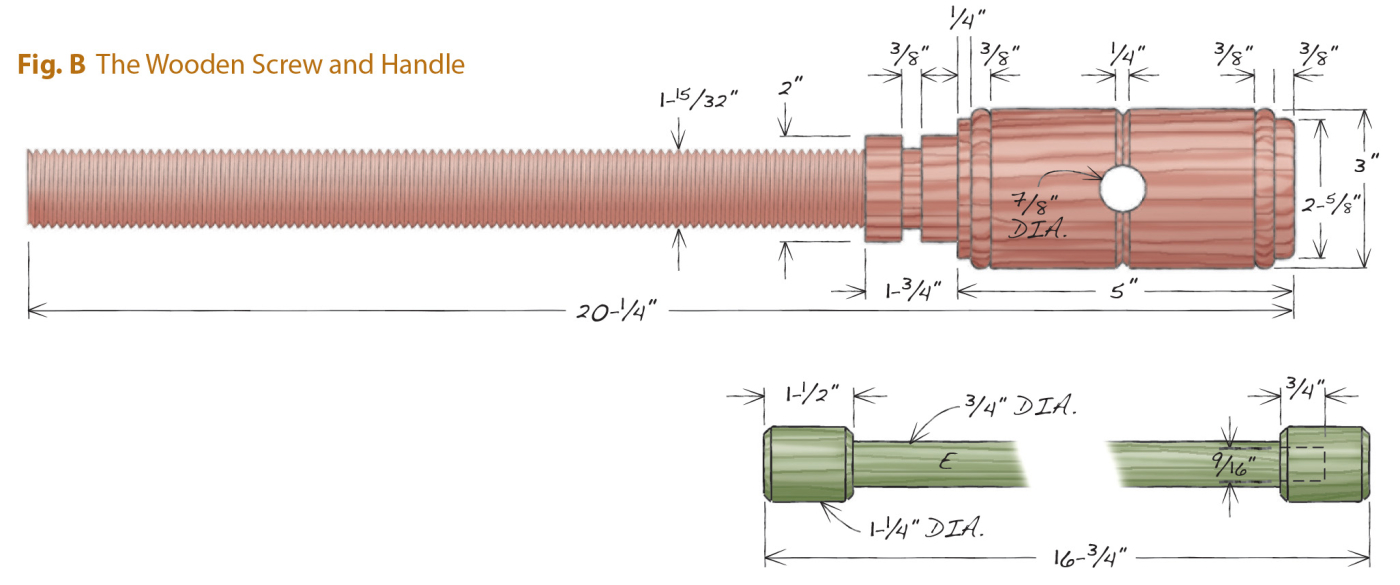

Determine the fixed jaw’s length by subtracting 16″ (the length required by the adjustable jaw) from the overall length of your bench, including the two end caps. For the 80-1/2″ long bench shown here, the fixed jaw measures 64-1/2″. This jaw contains equally spaced holes for bench dogs (Fig. C). It consists of notched, angled fill blocks (F) that are sandwiched between two rails (G). Make sure to have your bench dogs in hand before you build, so you can size the dog holes to fit.

5. Create the fixed jaw by gluing notched fill blocks between two rails. Use screws instead of clamps to streamline the process. The spaces between the segments become holes for bench dogs.

Mill blanks for the two 1-1/2″ thick rails and the 3/4″ thick fill blocks. Cut the blanks 3-13/16″ wide and allow extra length for trimming. Set the miter fence to 5˚ and use the tablesaw to cut the fill-block blank into nine 4-3/4″ long blocks and two extra-long blocks to go on the ends of the assembly. Cut a 1/4″ x 1-1/4″ notch in each fill block to allow the head of the bench dog to seat below the top surface. Drill a pair of countersunk pilot holes in each fill block and glue them on one of the rails, using spacers to create 1″ gaps (Photo 5). Make sure all the notches face up and to the right. Clamp each block until you drive in the screws; then remove the clamps. After all the blocks are fastened, remove the screws. Then glue and clamp the remaining rail. When the glue is dry, level the top of the laminated jaw and mill it to final 3-3/4″ width.

Square the jaw’s right end 4-1/2″ from the first dog hole. Then square the left end at the assembly’s final length (flush with the outside edge of the left end beam). Clamp the jaw to the front of the bench, level with the top and snug against the end beam’s dovetail. Transfer the dovetail onto the end of the jaw. Then remove the jaw and cut the dovetail socket in the end. Drill countersunk holes for the three 3/8″ x 6″ lag bolts that anchor the jaw to the bench, in the middle and 3″ from each end.

6. Install the fixed jaw with glue and lag bolts, making sure it’s flush with the existing bench top. The board glued on the bottom of the fixed jaw supports the Federal-style double-screw face vise.

Install the fixed jaw (Photo 6). Apply glue to the edge of the bench top and to the end cap’s dovetail. Lightly clamp the assembly in position. Then use a dead blow mallet to seat the dovetail joint. Level the assembly with the front of the bench and then tighten the clamps. Drill pilot holes through the three counter-sunk holes in the jaw and then install the lag bolts.

Modify the base

7. Modify the bench base by cutting off the fronts of both top rails. This allows moving the base forward to center it under the widened top. You’ll also have to cut a notch for the adjustable jaw’s guide bar.

Adding the two jaws makes the top front-heavy. To keep the bench from tipping forward, you’ll probably have to modify the base. On the trestle base shown here, the solution is to shorten the top rails (Photo 7). This allows moving the base forward under the top until it butts against the fixed jaw. You’ll also have to cut a slot for the adjustable jaw’s guide bar. It’s best to make this cut later, when you’re installing the adjustable jaw.

The adjustable jaw

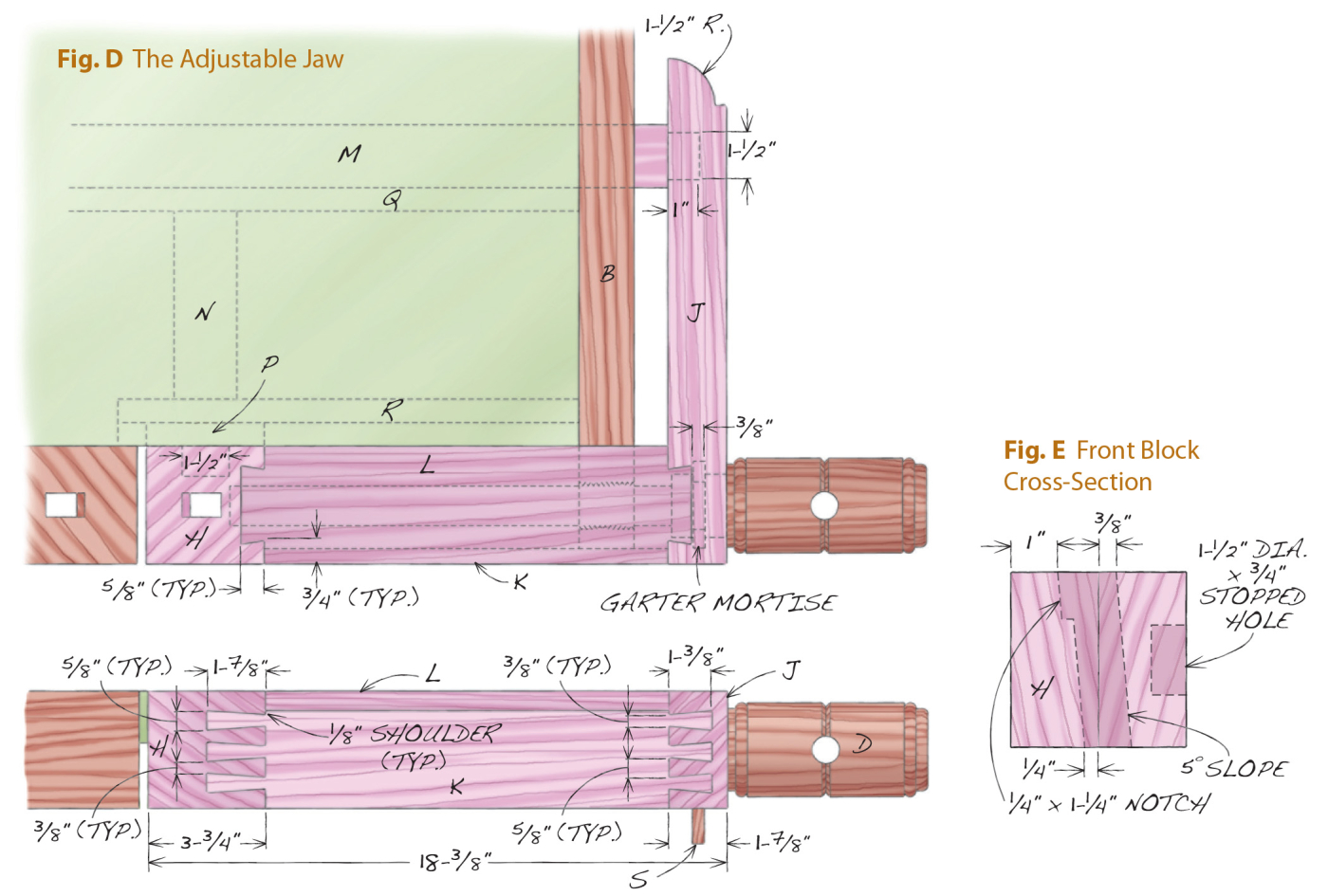

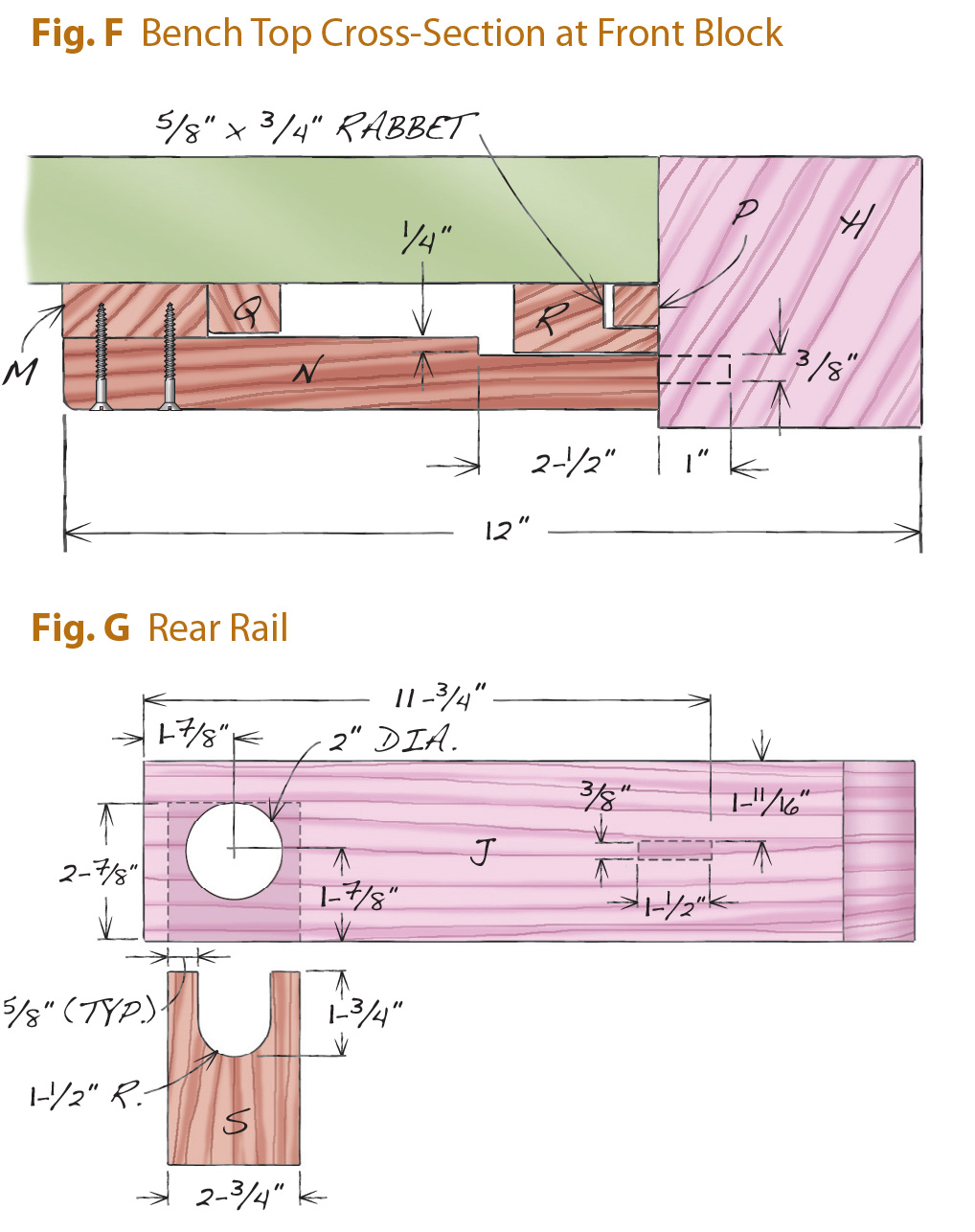

The adjustable jaw (Figs. D–G) looks like a narrow box, but it’s actually a rectangular frame consisting of a front block (H), a rear rail (J), side and top pieces (K and L), a guide bar (M) and a cross brace (N). The front block, rear rail, side and top form the box that’s the business end of the jaw: It houses a bench dog and the wooden screw that applies the clamping pressure. This box is supported by the right end cap and kept level with the bench top by a tongue (P) that’s attached to the front block. The guide bar and cross brace slide under the bench top. The guide bar, mortised into the rear rail, housed in the end cap and supported by a rub rail (Q), holds the adjustable jaw against the front of the bench as it slides. The cross brace completes the frame by connecting the guide bar to the front block.

8. Make the adjustable jaw’s front block in two pieces to create its angled dog hole. Cut a shallow groove across the grain in each piece. Then saw the angled shoulders and clear the waste.

The biggest challenge in building the adjustable jaw is cutting the angled dog hole in the center of the front block (Fig. E). The trick is to make this block in two pieces (Photo 8). Cut a pair of identical 1-7/8″ x 3-3/4″ x 3-3/4″ blocks. Then cut a precisely centered 1/4″ deep x 3/4″ wide dado across the grain in each block, using a dado set and a miter gauge with a fence and a stop block. Clamp the blocks together with the dadoes facing each other and lay out the ends of the angled dog hole on the top and bottom faces of both blocks. Use these depth marks and a hand saw to cut the angled shoulders. Clear the waste with a chisel and cut the notch on one end. Then carefully glue the two blocks together, using a spacer to precisely align the dadoes.

9. Glue the front block together to create the dog hole. Then drill it to house the wooden screw, dovetail it to fit the side and top pieces and mortise it for the cross brace.

Cut dovetails on both ends of the adjustable jaw’s side (K) and top (L). (Note that the side’s front-block dovetails are longer than its rear-rail dovetails.) Transfer the dovetail locations to the front jaw. Then cut the sockets and fit the joints (Photo 9).

10. The front block slides in a groove created by attaching a rabbeted cleat to the bench. A tongue fastened to the jaw fits the groove and keeps the jaw flush with the bench top as it slides.

The front block’s back face has a tongue and a mortise (Fig. F). The tongue (P) holds the block level with the bench top as the ajdustable jaw opens and closes (Photo 10). It slides in a groove created by a rabbeted cleat (R) that’s attached to the bottom of the bench top. The mortise in the front block houses a tenon on the cross brace (N). Fasten the rabbeted cleat under the bench top and then attach the tongue with glue and screws and chop the mortise.

Cut the rear rail (J, Fig. G) to length and width. Routing a profile on its back end is optional—a matter of taste. Lay out and cut the dovetail sockets on its top and front end and chop the stopped mortise for the guide bar (M) on its inside face. Cut the guide bar and fit its tenon to the mortise in the rear rail. Cut and fit the cross brace (N). Note that it’s rabbeted to fit around the rabbeted cleat (R).

11. Install the partially assembled adjustable jaw to check the alignment of the three holes for the wooden screw. Then install the top and test the jaw to make sure it slides smoothly.

Lay out and drill holes for the wooden screw in the front block and rear rail. To make sure these holes align with the threaded hole in the end cap, dry-assemble the adjustable jaw’s side, front block and rear rail and position the assembly on the bench. Mark the hole in the rear rail after butting it against the end cap. To mark the hole in the front block, slide the assembly back until the block butts against the end cap. Before marking each hole, make sure the top edges of both pieces are flush. Drill a 1-1/2″ dia. x 3/4″ stopped hole in the front block and a 2″ dia. through hole in the rear rail. Re-assemble the adjustable jaw, add the guide bar and cross brace, and test its operation on the bench (Photo 11). Make sure there’s a small gap between the right end cap (B) and the real rail (J) when the jaws are tightly closed.

Final assembly and mounting

12. Locate the mortise for the garter that secures the wooden screw in the adjustable jaw. Position the screw with its head snug against the jaw’s rear rail. Then transfer the garter groove’s location.

Turn the adjustable jaw upside down to locate the mortise for the garter that holds the wooden screw (Photo 12 and Fig. G). Butt the head of the screw against the rear rail and center its collar over the hole. Transfer the locations of both garter groove shoulders to the jaw and use these marks to chop the mortise. Make the garter (S).

13. Mount the adjustable jaw and thread in the screw until its head seats against the rear rail. Install the garter and then test for smooth operation.

Glue the adjustable jaw together in stages. Start by gluing the dovetailed side, top, front block and rear rail to create the body. Mount the body on the bench. Then work from underneath to glue and attach the guide bar and cross brace. Install the wooden screw by threading it through the hole in the end cap until it seats against the jaw’s rear rail (Photo 13).

14. Flip over the bench top and install a rub rail against the guide bar to ensure the adjustable jaw remains parallel to the front of the bench top as it opens and closes.

At the other end, the screw will be housed in the hole in the front block. Tap in the garter to lock the screw in position. Finish by fastening the rub rail (Q) to track the guide bar as the vise opens and closes (Photo 14). On this bench, the rub rail reinforces the notch in the base that houses the guide rail. If your installation doesn’t allow notching the base, this rub rail is essential for the vise to track properly.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.