We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Basements aren’t recommended in this part of North Carolina, and our lot was too small for a detached shop.

That meant my woodworking was either going to have to dodge cars in the garage—or I could turn the space above the garage into a shop.

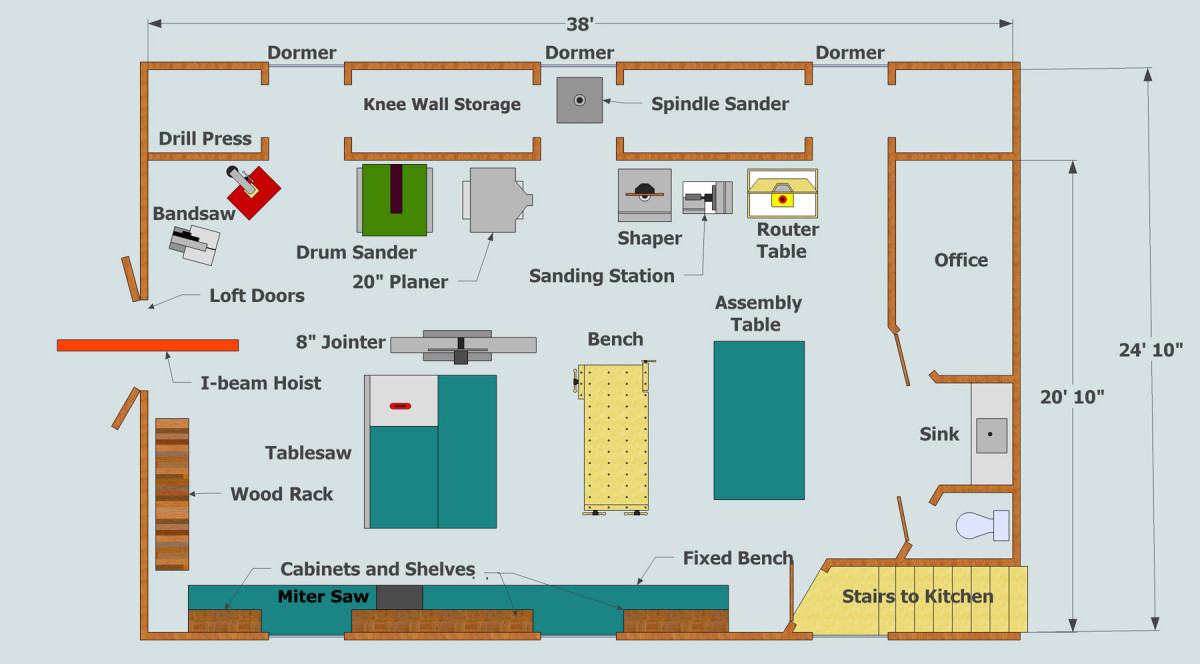

As this was going to be my first real shop (my military career kept me moving from place to place), I wanted to do it right. To get the most out of the upper story, my builder and I had to rework the original house and garage plan. We added a third garage bay, reinforced and lowered the floor, relocated the stairwell and changed the gabled roofline to create a full 8′ rear interior wall. We also added dormers and rear windows for natural light. All this added up to almost 900 sq. ft. of glorious shop space.

As this was going to be my first real shop (my military career kept me moving from place to place), I wanted to do it right. To get the most out of the upper story, my builder and I had to rework the original house and garage plan. We added a third garage bay, reinforced and lowered the floor, relocated the stairwell and changed the gabled roofline to create a full 8′ rear interior wall. We also added dormers and rear windows for natural light. All this added up to almost 900 sq. ft. of glorious shop space.

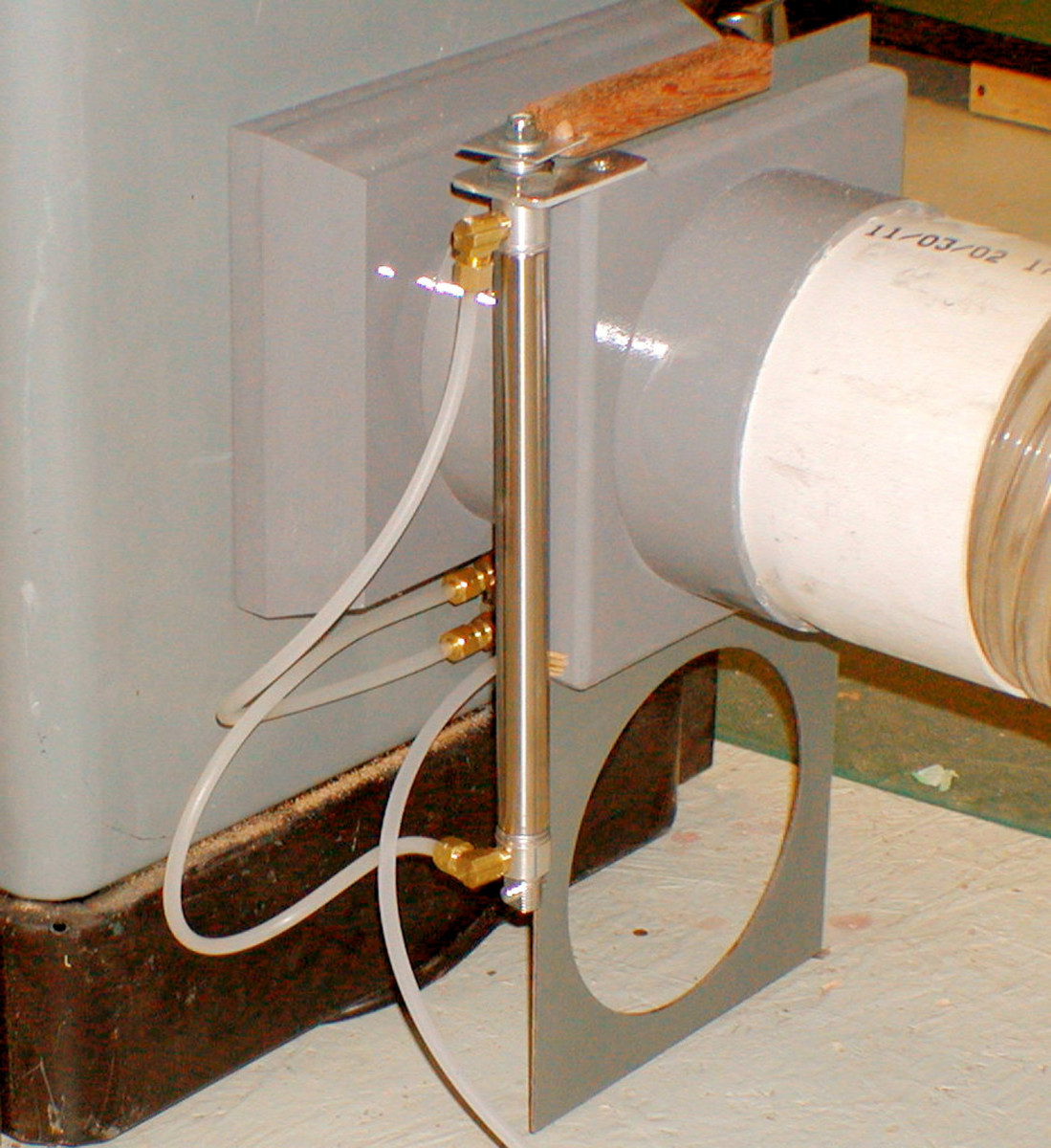

I solved the largest conundrum—how to get the heavy machinery and lumber into the shop—by designing a stow-away I-beam hoist that can lift almost anything

I solved the largest conundrum—how to get the heavy machinery and lumber into the shop—by designing a stow-away I-beam hoist that can lift almost anything

up or down without assistance. Small items travel the old-fashioned way—I carry them up the stairs!

I took my time thinking through all aspects of shop construction, from wiring and plumbing to dust collection and tool layout. This includes storing my wood vertically to make access easier, building mobile bases to facilitate tool set-up and running compressed air lines throughout. To increase efficiency, I’ve designed a fully automatic dust-collection system with self-actuated blast gates that open or close when each tool starts or stops. I designed and built all the shop cabinets using oak harvested from the lot before construction began. I also built my own adjustable-height workbench.

I took my time thinking through all aspects of shop construction, from wiring and plumbing to dust collection and tool layout. This includes storing my wood vertically to make access easier, building mobile bases to facilitate tool set-up and running compressed air lines throughout. To increase efficiency, I’ve designed a fully automatic dust-collection system with self-actuated blast gates that open or close when each tool starts or stops. I designed and built all the shop cabinets using oak harvested from the lot before construction began. I also built my own adjustable-height workbench.

Now that I have a full complement of machine and hand tools, I’m able to tackle nearly any woodworking project. As evidenced by my shop cabinets, I have a special affinity for Arts and Crafts design. I’ve accepted a few commissions, but I primarily build furniture for my family and friends. I’m still tinkering and have just recently invented a new jig that I was fortunate enough to license to a respected U.S. manufacturer of woodworking accessories. With a little luck it will be on the market this fall. –Alan Schaffter

Now that I have a full complement of machine and hand tools, I’m able to tackle nearly any woodworking project. As evidenced by my shop cabinets, I have a special affinity for Arts and Crafts design. I’ve accepted a few commissions, but I primarily build furniture for my family and friends. I’m still tinkering and have just recently invented a new jig that I was fortunate enough to license to a respected U.S. manufacturer of woodworking accessories. With a little luck it will be on the market this fall. –Alan Schaffter

Editor’s note: This article originally appeared in American Woodworker #151. Alan’s jig did in fact make it to market, and is still available today. Learn more about it here.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.