We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Master Your Mortiser

Shop-tested techniques

guarantee great results.

By George Vondriska

The first time I used my benchtop mortiser was almost

my last. It was tedious to set up, difficult to operate and

my results stunk. But now the mortiser is my first

choice whenever I have mortises to cut. It turns out the problem

wasn’t the machine—in fact, the newest benchtop mortisers

do a great job. Instead, the problem was

my inexperience. I discovered there’s a learning curve to

successfully setting up and operating a mortiser.Read on to learn the techniques I use to get

consistent, professional-quality results from my

mortiser. If you follow these methods and

mortising is still a struggle, your

machine’s fence and hold-down may

need tuning. |

|

Click any image to view a larger version.

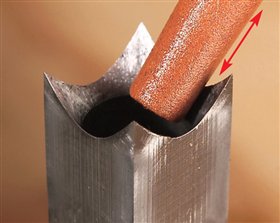

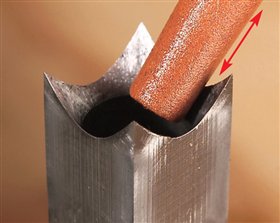

The hollow chisel and auger

bit work together to cut

square mortises. The auger

drills a hole and then the chisel squares the corners.

Chips produced while cutting are lifted by the auger and ejected

through holes in the chisel. |

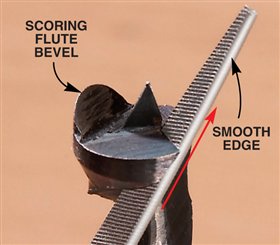

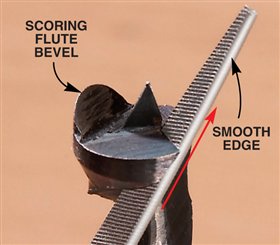

Start sharp, stay sharp

You’ll get better results with less effort

if you take a few minutes to sharpen

your bit and chisel before each use.

Sharpen the auger’s flutes with a small

auger file (this one’s from Nicholson’s

miniature file set #42030, about $17 at

Amazon.com). An auger file has

smooth edges that won’t harm adjacent

surfaces during close work. Hold

the file flat on the bevel and move it

forward only, toward the cutting edge. |

|

|

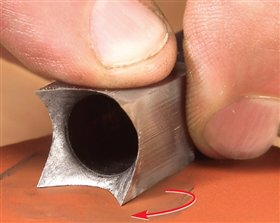

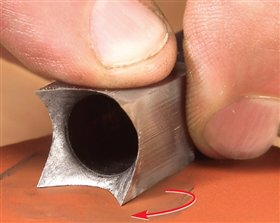

Sharpen the chisel’s inside bevels with

a round slipstone (about $15 at woodworking

specialty stores). |

|

|

Hone the outside faces on a flat stone,

using even pressure and a circular

motion. |

|

|

________________________________________________________________________________________

Insert a dime to install the bits. To work properly, the auger must slightly

project beyond the hollow chisel. Here’s an

easy way to achieve the perfect projection.

Temporarily install the chisel with a dime

squeezed between its shoulder and the

machine. Then lock the auger in position with

the edge of its cutting flute even with the

chisel’s tips. Remove the dime, slide the chisel’s

collar tight to the machine and lock it. |

|

|

Instantly align the chisel. To create perfect mortises,

the chisel must be parallel to

the fence. It’s easiest to place

a board against the fence,

move the fence forward and

pivot the chisel until its face

is flush with the board. |

|

|

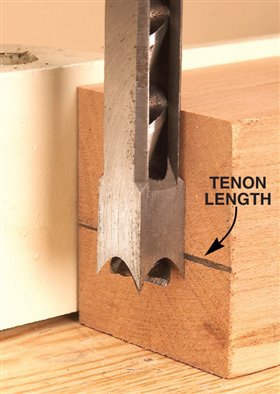

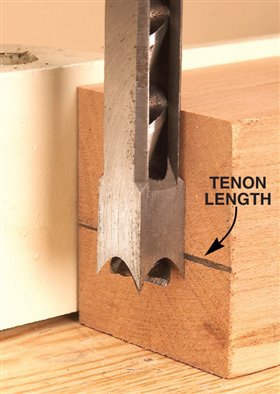

Arches set the depth of cut. Mark the tenon’s length on the

end of the workpiece. Then

lower the chisel. Lock the

depth-of-cut stop when the

tops of the chisel’s arches are

even with your line. This

method assures that your

tenons will seat properly,

because it automatically creates

a mortise that’s slightly

deeper than the tenon’s length. |

|

|

Stay cool. Make life easier for the chisel and auger

by spritzing them with cutting lubricant

before each use. This prevents overheating,

helps the auger to evacuate

chips effectively and allows the chisel to

smoothly enter and exit the workpiece.

It’ll also help your ears; lubricating

keeps the bits from squealing.

Source

Empire Manufacturing, empiremfg.com, 866-700-5823, OptiCut XL,

$6 for a 2-ounce bottle. |

|

|

Let the chisel & auger do the work.

Synchronize your feed rate with the auger’s cutting action

by watching the flow of chips exiting the chisel.

Don’t try to overpower the machine; easy—but firmly—does it.

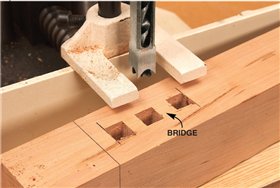

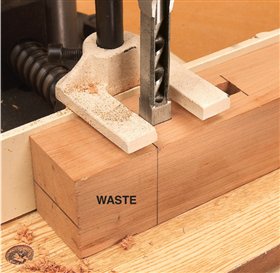

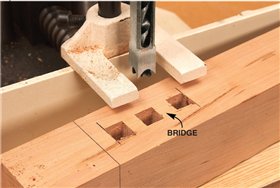

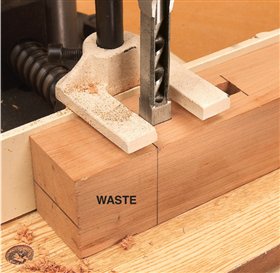

Connect square holes to create a mortise. Establish the ends of the mortise first. Then clear out the middle: First cut individual holes spaced by slightly less than

the width of the chisel. Then go back and remove the remaining

bridges. Always engage the chisel on all four sides or on

two opposite sides, but never on three sides. Engaging three

sides can deflect—and even break—the chisel. |

|

|

Make a cleaning pass. The first set of holes you cut will leave considerable

debris in the bottom of the mortise. The mortise sides

may also be slightly rough. A second pass, made with

numerous plunges very close together, cleans both

the bottom of the mortise and the sides. |

|

|

Mortise before cutting to length. When a mortise starts near the

end of a piece, as on the table

leg shown here, leave the piece

long until after the mortise is cut.

Then you’ll always have material

under both arms of the holddown.

This greatly reduces the

chances of jamming the chisel. |

|

|

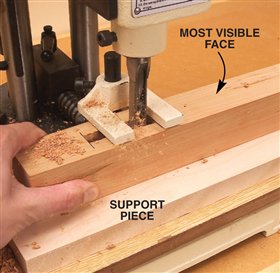

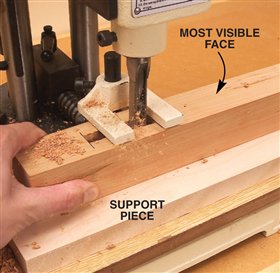

Cut through mortises from the visible face. Only one side of a through mortise shows, so

it only needs one perfect face. Cut these mortises

with the most visible face up—this side

will be cleanly cut. Support the exit side with

a scrap piece to reduce splintering. To keep

the bit from wandering or overheating, cut

the mortise in stages, halfway first, then all

the way through. |

|

|

Let the grooves be your guide. When you use mortises and

tenons to join rails and stiles on

frame and panel constructions,

cut the grooves for the panel

first. Then use the grooves to set

up and guide the mortising chisel

when you cut the mortises. |

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.