We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

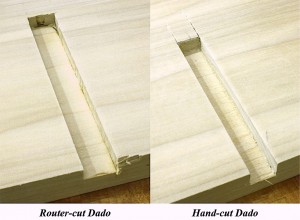

This week I was in the shop working on an upcoming magazine article. On the case back there are two dados that locate and hold the drawer dividers of the project. For me, that generally means I pick up my router and get busy. This time, because I needed two matching slots, I decided one would be router-cut and for the second I would use hand tools. Is one method better than the other?

This week I was in the shop working on an upcoming magazine article. On the case back there are two dados that locate and hold the drawer dividers of the project. For me, that generally means I pick up my router and get busy. This time, because I needed two matching slots, I decided one would be router-cut and for the second I would use hand tools. Is one method better than the other?

For my router setup I needed a 5/8″-diameter, top-mount bearing router bit, my router and one of the most-used jigs in my shop, a square-platform jig; one of the “Dirt-simple Router Jigs from the November 2008 issue (#172).  I clamp the jig on the left side of my layout lines – do this when using any router jig because the tool rotation pushes in that direction – and set the depth of cut making sure the bearing is riding along the jig. I then make the cut. (One thing I forgot to do was to score or saw the beginning of the cut to prevent blow-out.) Overall, this process took about three minutes from start to finish.

I clamp the jig on the left side of my layout lines – do this when using any router jig because the tool rotation pushes in that direction – and set the depth of cut making sure the bearing is riding along the jig. I then make the cut. (One thing I forgot to do was to score or saw the beginning of the cut to prevent blow-out.) Overall, this process took about three minutes from start to finish.

To cut the dado using my hand tools, I began with my dovetail saw and cut the two sides of the dado. I went to final depth at the open end, and ran past the housed end in typical over-cut fashion – half-blind dovetail work has made over-cut lines perfectly acceptable to my woodworking mind. Chisels removed most of the waste. I used my chisel bevel down for some of the work and bevel up as I began to reach the final depth.

To cut the dado using my hand tools, I began with my dovetail saw and cut the two sides of the dado. I went to final depth at the open end, and ran past the housed end in typical over-cut fashion – half-blind dovetail work has made over-cut lines perfectly acceptable to my woodworking mind. Chisels removed most of the waste. I used my chisel bevel down for some of the work and bevel up as I began to reach the final depth.  The last step is to use a router plane to level the dado to its final depth. This entire process is described in more detail in the November 2013 issue (#207) in the “6-board Chest” article.

The last step is to use a router plane to level the dado to its final depth. This entire process is described in more detail in the November 2013 issue (#207) in the “6-board Chest” article.

The hand-tool process took about 10 minutes give or take. (And there was the time spent taking photos for each of the processes – one for the power setup and six or so for the hand-tool work.)

In the end, I spent more time with the hand-tool process, but not by a significant amount. I worked harder cutting the dado by hand, but that’s not necessarily a bad thing. I think the dado cut by hand looks better, but that’s nothing anyone would see until the piece is trash or re-worked. Truth is, I didn’t discover that one method is better than the other. It’s just how you choose to work.

I did, however, discover a flaw in the justification that many hand-tool users suggest as to why they choose hand tools. For many hand-tool devotees, the main reason they give for selecting this process is that hand-tool usage is quiet. More quiet than when using power tools. In this technique, I disagree. My router cranked out high decibels for about 40 seconds, but every mallet whack to my chisel spiked the decibel meter into the stratosphere. And I lost count of the number of whacks taken.

So what is the answer? Simple. Choose your method, and get to work.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

“half-blind dovetail work has made over-cut lines perfectly acceptable to my woodworking mind.”

Really?!? If that is the case, you should stick to power tools.

The best thing written was: “Choose your method, and get to work.”

Paul

Aloha Glen,

Well, it depends on why your woodworking. If your trying to make dollars, speed is king. And the method used will reflect the cost of the job (solid wood vs. melamine).

As a 35+ yr. carpenter (2nd generation Gen. building cont.) making a jewelry box, or cell phone stand for my daughter always brings a special joy to the project.

Not only because of whom the project is intended, but I’m allowed me to get creative.

For example upper end custom kitchen cabinets is time consuming, no doubt about it. The parameters are already set (material, method, color, and finish), you just have to meet the deadline. And we do use a jig for joints (dovetails) because it’s repeatable, and fast.

But a China hutch, or an entertainment center (large single pieces of furniture) I’ll choose hand tools for this simply, because I love the work. Don’t get me wrong, I’m using three sets of bench chisels that way I don’t have to stop to sharpen (until the end of the day).But the finish just can’t be beat!

I’ve been working on a lathe for the last two years, because I believe all woodworkers should. It opens up an additional level of creativity, and possibility.

So when you say your doing a bookcase for an article, don’t forget the rest of us who (envy what you do), and do it to try and make a living while trying to advance our skill.

I know you love what your doing, it shows in your work, and writings! Keep it up!

Aloha

The noise issue is a hornet’s next for sure. I don’t care one way or the other.

But when I have a whirring power tool in my hand I watch my hand’s proximity to the tool (this includes power jerking as I got hurt with a 7″ wire buffer once) so I am not watching the work nearly as much as I like too. I could get more experience with the tools and overcome this though. Eventually.

Green schmeen. If we were worried we’d all buy horses. I don’t see that many parked at Walmart.

The cut wood will leave a nice smell regardless of method. Personally I prefer the crisp smell of fried electrons along with it, rather than the stink of body funk from doing labor that isn`t necessary. YMMV.

Glen, Glen, Glen,

You have to realize that there is a difference in the type of noise. Power tool decibels come from a carbon sucking, planet destroying source and are therefore evil. Hand tool decibels on the other hand comes from a beneficial source, good old muscle power and so the noise is actually good for you.

Bob Lang

I find I am not so particular about the method so long as the end product is solid. As it happens I’m better set up to do this by hand, but if my router was kept in a better state of readiness, I’d probably be just as comfortable doing it with a router.

I’m going to go for a power tool every time over reading a 200+ yr old book that basically says since we don’t have power tools do it like this…..

If the noise bugs me I can always do something crazy like put hearing protection on.

Many early texts discuss cross grain cleaning of dados and other similar joints as paring, not mallet work. The work is done with a long paring chisel that’s held against the shoulder for leverage and force. No noise, no dust.

Somewhere along the line we forgot what a paring chisel is for.

Was the board exactly 5/8″ and it fit precisely into the groove made by that bit? Or, did you leave the board slightly thicker and then plane it to fit? I have seen jigs that you fit to the board on each side and then run an undersized bit up one side and down the other so the bit and board don’t have to be exactly the same. Would the hand tool method be more convenient if you weren’t confident that the board was just the right thickness?

I like that you show two alternatives. The noise comment, however, seems silly–do you wear hearing protection when you strike your chisels?. Maybe you should use a urethane covered mallet. You are fast with power tools, especially for repetitive tasks, and that is an advantage you don’t have to apologize for. Just keep showing both hand and power tool methods and the magazine will do just fine.

I would like to see this noise theory digitized….or bagged and weighed.

Much more nasty noise from the power router and then there is the fine dust it produces and no matter how hard you try some is always put into the air. I find it easier to get a much more accurately located groove on one off pieces using hand tools.

Then there is the deep satisfaction I get from the hand tool method that feeds my soul. Fancy remark! Yes but using our hands in a skillfull way is fundamental to mankind.

Noise? Geez, man, how hard were you hitting that chisel? Depending, you might ought to be able to clean out the waste pushing the chisel by hand or with fairly light mallet blows. Come on, a wooden mallet or dead blow hammer making noise comparable with a screaming router? What wood was it?

I’ve always said that I make more noise sawing dovetails by hand than I do cross cutting a board on a table saw.