We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I make a lot of shelving from hardwood plywood, covering the panel edges with 1⁄4“-thick solid-wood edging. The edging, which is oversized in length and width, is trimmed flush with the plywood panel after the glue cures. Although the projecting edging can be routed using a flush-trim bit, it tends to tear out if there is more than about 1⁄16” overhang.

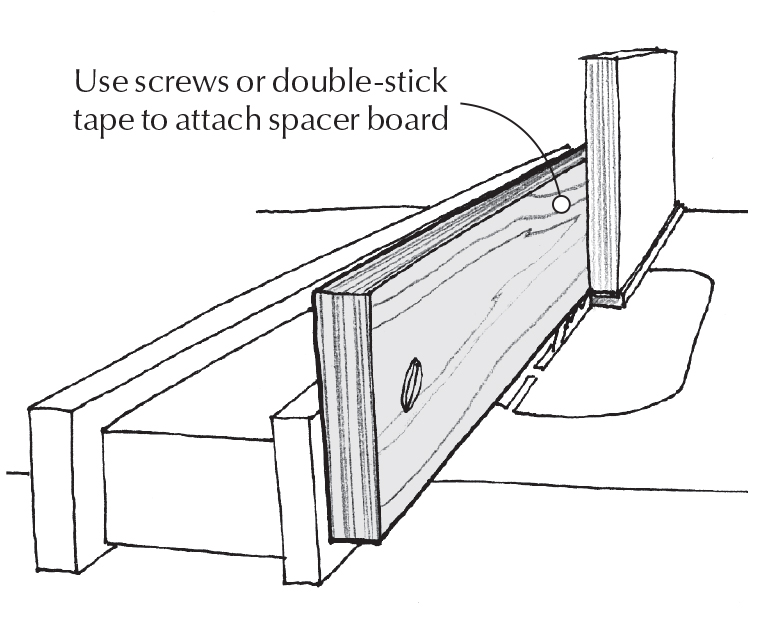

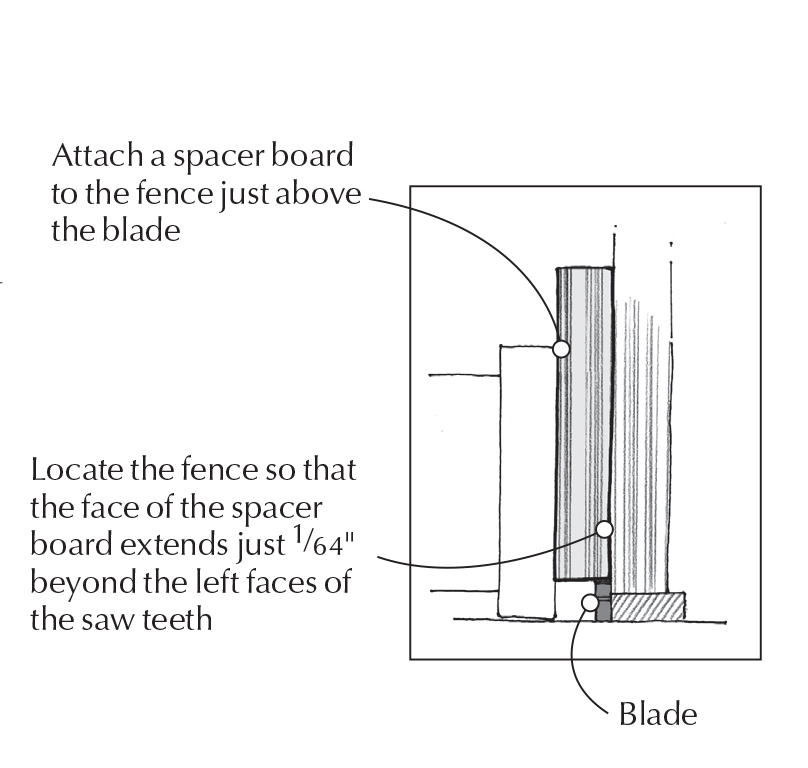

I find that, whenever possible, it’s best to saw off the overhang on the table saw by raising the blade about 1⁄2” above the table, then attaching a spacer board to the fence just above the blade using double-stick tape. I locate the fence so that the face of the spacer board extends 1⁄64” or so beyond the left faces of the saw teeth. Now, when feeding the workpiece on edge against the spacer, the edging will be trimmed just proud of the panel surface, leaving only a small amount of waste to remove by planing, scraping or sanding.

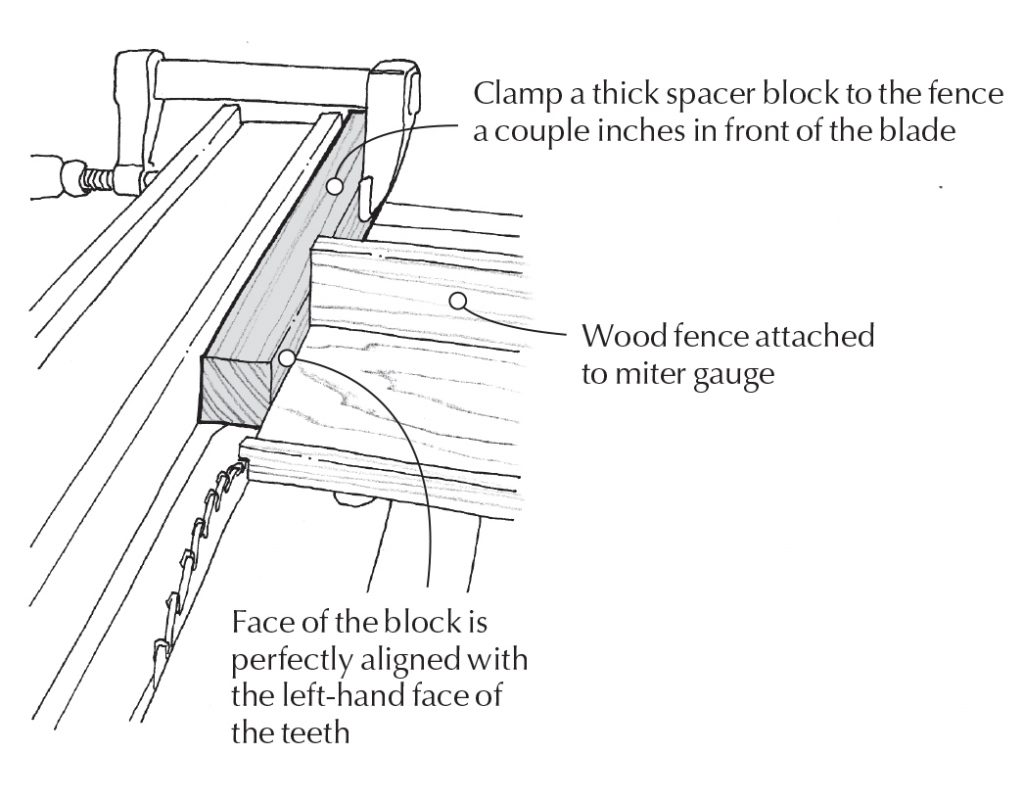

After trimming the long edges, I set up to trim the ends. This time, I raise the blade about 1⁄4” higher than the edging in thickness, then I clamp a thick spacer block to the fence a couple inches in front of the blade. I position the fence so that the face of the block is perfectly aligned with the left-hand face of the teeth. To trim the edging, I first butt the end of the workpiece against the spacer block, with the overhanging edging between the block and the blade, then feed the workpiece forward, trimming the edging perfectly flush with the end of the panel. Use a miter gauge to feed narrow workpieces. — Paul Anthony

After trimming the long edges, I set up to trim the ends. This time, I raise the blade about 1⁄4” higher than the edging in thickness, then I clamp a thick spacer block to the fence a couple inches in front of the blade. I position the fence so that the face of the block is perfectly aligned with the left-hand face of the teeth. To trim the edging, I first butt the end of the workpiece against the spacer block, with the overhanging edging between the block and the blade, then feed the workpiece forward, trimming the edging perfectly flush with the end of the panel. Use a miter gauge to feed narrow workpieces. — Paul Anthony

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.