We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Achieving exact thickness is really important when making splines to reinforce box corners. The splines have to fit perfectly in the saw kerfs—a few thousandths of an inch one way or the other can make a big difference.

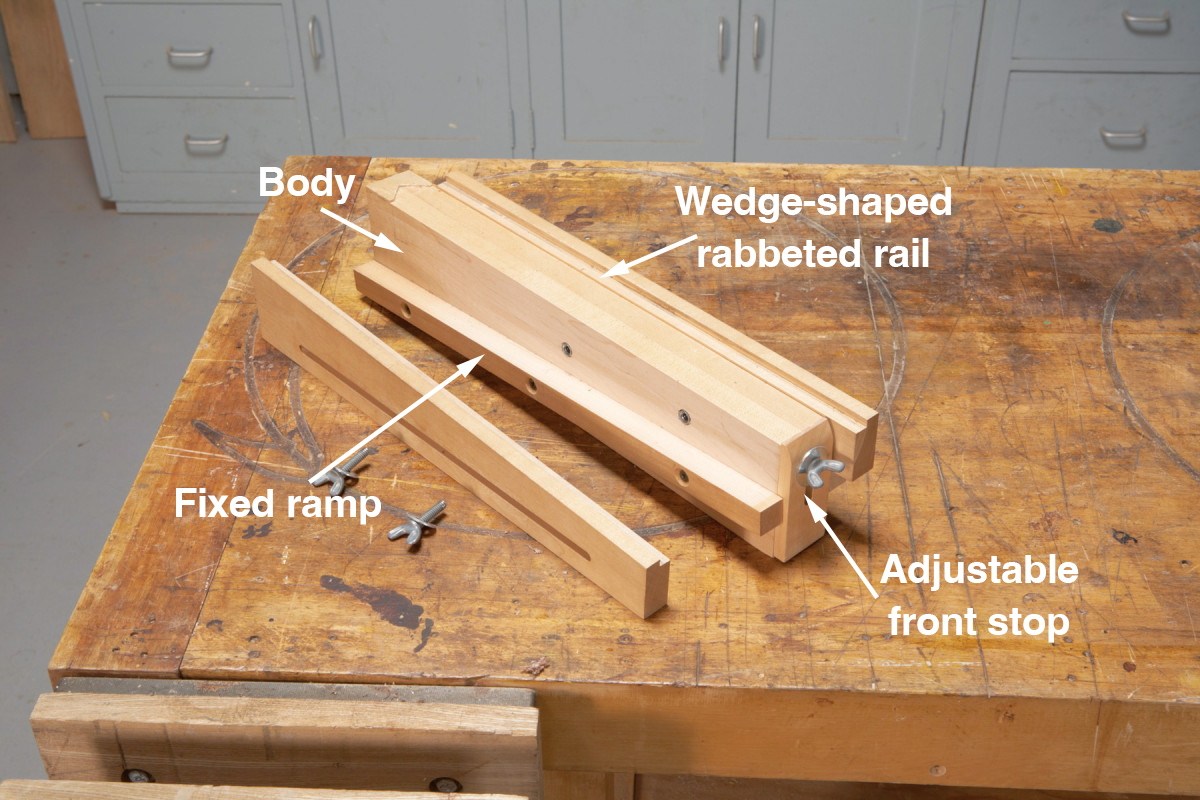

I cut my spline material on the tablesaw, making it a bit thicker than needed, then plane it by hand to exact thickness using this adjustable jig.

Here’s how the jig works. The plane rides on rabbets cut into two rails. Both rails are tapered, like a wedge. You adjust the height of each rail by sliding it on a fixed ramp attached to the jig’s body. To plane a spline, place it on the body of the jig, snugged up against the adjustable front stop, and start in. When the plane stops making shavings, you’ve reached final thickness.

Here’s how the jig works. The plane rides on rabbets cut into two rails. Both rails are tapered, like a wedge. You adjust the height of each rail by sliding it on a fixed ramp attached to the jig’s body. To plane a spline, place it on the body of the jig, snugged up against the adjustable front stop, and start in. When the plane stops making shavings, you’ve reached final thickness.

My jig holds pieces up to 1-1/2″ wide, 12″ long and 1/4″ thick. It’s designed for a No. 3 plane, but it would be easy to make a larger version to fit a wider plane. All of the parts are 3/4″ thick hard maple; the body is glued up from two pieces. –Doug Perlick

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.