We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

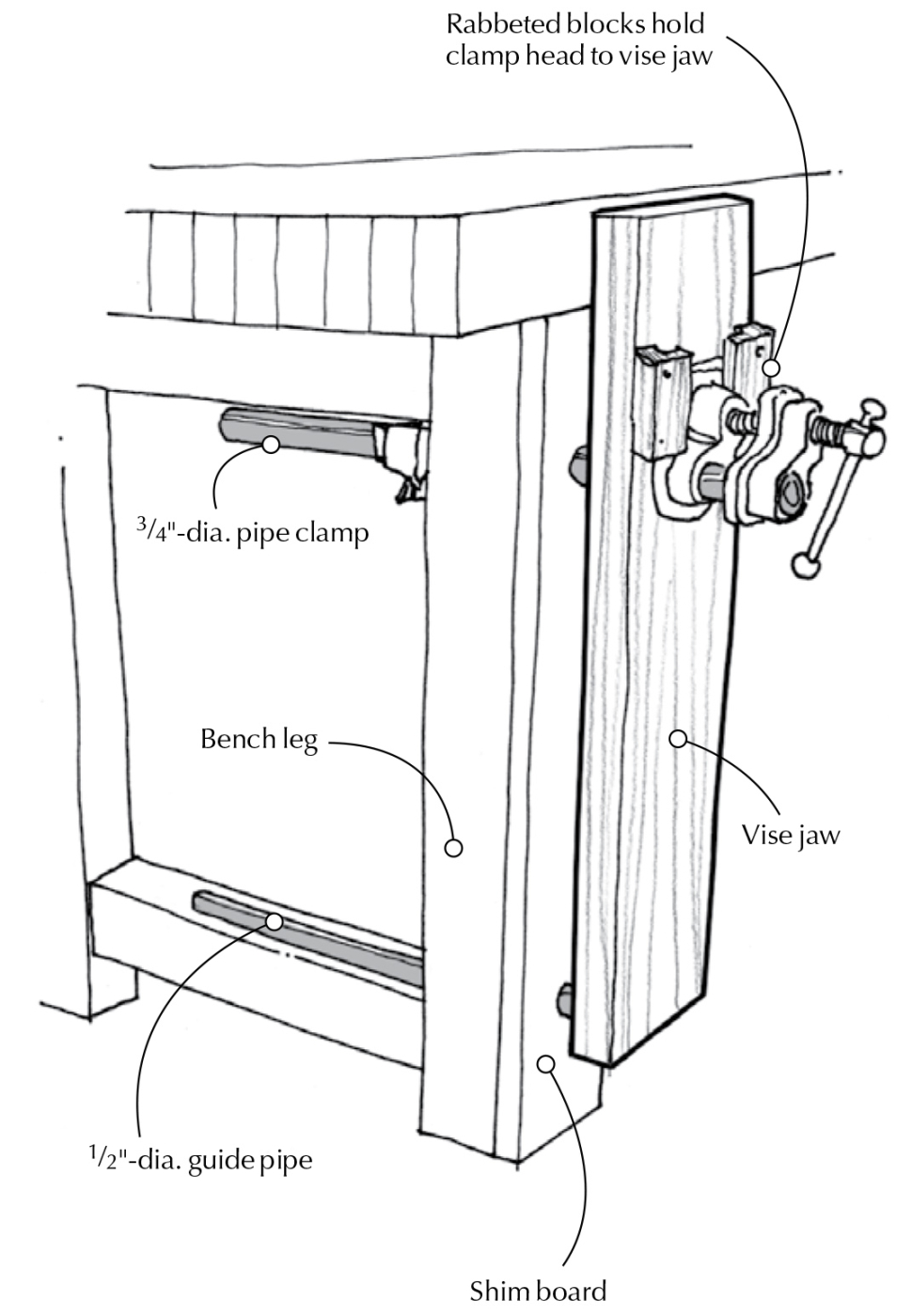

My tight finances forced me to devise an alternative to an expensive bench vise. This simple leg vise – cobbled together from a board, a 3⁄4“-diameter pipe clamp, and a short length of 1⁄2“-diameter pipe – works fine for many of my needs. As seen in the drawing, the pipe clamp extends through the vise jaw and bench leg, with the clamp’s screw jaw attached to the vise jaw, and the opposite clamp jaw resting against the inner face of the bench leg. The “guide” pipe, screwed into the lower end of the vise jaw, floats in a hole in the bench leg to help stabilize the vise jaw and prevent it from rotating. It also jams in its hole under pressure to serve as a sort of holdfast for the jaw. A shim board attached to the face of the bench’s leg brings its clamping surface flush with the front edge of the benchtop.

To build the vise, I clamped the wooden vise jaw against the leg and drilled a 1″-diameter hole for the 3⁄4“-diameter pipe clamp, using a spade bit and a portable drill guide to keep the hole perpendicular to the face of the bench leg. After removing the jaw, I drilled the 1″-diameter hole for the guide pipe. I then aligned the jaw again and drilled through the guide-pipe hole from behind the leg to locate the lower hole in the jaw. To attach the guide pipe, I simply screwed its threaded end into an appropriately sized blind hole in the jaw, although you could screw it into a pipe flange fastened to the jaw. I attached the head of the pipe clamp to the jaw using rabbeted wood blocks, but you could drill holes through the jaw and attach it with screws instead for a neater, less obtrusive appearance.

The vise is easy to use. For most of my clamping needs, the throw of the clamp screw provides enough clamping capacity. However, when I need to clamp large pieces, it’s easy to reach behind the leg to adjust the rear clamp jaw for a larger opening. On the few occasions that the lower guide pipe won’t lock in position under pressure, I simply clamp a pair of locking pliers onto the pipe against the front of the leg. – Thomas Porter

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.