We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Woodworkers tend to have very strong feelings about the different ways of doing things – and handplanes is one of those subjects where opinions can vary wildly and discussions can even get pretty heated. There are three main arguments about handplanes: bevel orientation, number of planes to use and body type.

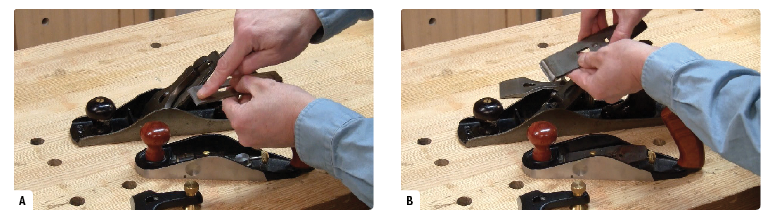

Bevel orientation refers to the way the iron sits in the plane. Shown above are a low angle bevel-up bench plane (front) and a bevel-down bench plane (back).

In the bevel-up plane, the iron sits with the bevel facing up (A). In the bevel-down plane, the iron sits in the plane with the bevel facing down (B). Except for early planes, most bevel-down planes have a chipbreaker mounted on the back of the iron, also known as a double iron. Sometimes people confuse the chipbreaker for the cutting bevel. The function of the chipbreaker is to curl the chip upward as the cutting edge lifts it off the wood.

For bench planes, while bevel-down planes are more common, there are plenty of people who swear by their bevel-up planes, in various sizes. Block planes are bevel-up.

Number of planes refers to having a dedicated plane for each of the three functions of roughing, flattening and smoothing (versus using a single, versatile plane for all functions, with different irons and setups). A three-plane setup like the one above consists of smoother, jack and jointer planes (front to back); each one is dedicated to a specific purpose. Jack planes tend to be the ones used for multiple purposes, especially with bevel-up planes.

Body type refers to wooden or metal planes, and overall design. Above left to right are three wooden styles: an antique all-wooden plane, a transitional metal and wooden plane, a modern wooden plane and two metal bodied planes. Another style of metal bodied plane is an infill plane (not shown). All of these types work, as evidenced by the work people have done with them. Each one has its own balance and feel. Switching between planes is a little like switching between different types of vehicles when you’re driving. You need to relearn the skills a bit as you go from one to another. Whichever style you use, make sure it holds its iron well. A plane that slips and won’t hold its adjustment is extremely frustrating to use.

There’s nothing wrong with mixing styles. Use whichever plane works well for you for a particular function.

Above is comparison of edge shavings taken off the same board by three different tools: a wooden jack plane, a #7 jointer and a #4 smoother. This is a perfect example of coarse, medium and fine, showing what it means to use the tool that takes the biggest bite. The jack shaving is the thickness of cardboard, the jointer shaving is the thickness of printer paper, and the smoother shaving is the thickness of tissue paper. With the irons at these current depths, the jack shaving that this plane produces is three-four times the thickness of the jointer shaving, which is in turn about 10 times the thickness of the smoother shaving that this plane produces. One stroke of the jack is equal to three or four of the jointer, and it’s equal to 20 or 30 of the smoother. That’s why it’s important to use the plane appropriate to the job you’re doing. That’s what makes the work efficient.

For more great information about using hand tools from sharpening to stock preparation to joinery, check out Steve Branam’s “Hand Tool Basics,” available now at ShopWoodworking.com.

For more great information about using hand tools from sharpening to stock preparation to joinery, check out Steve Branam’s “Hand Tool Basics,” available now at ShopWoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.