We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

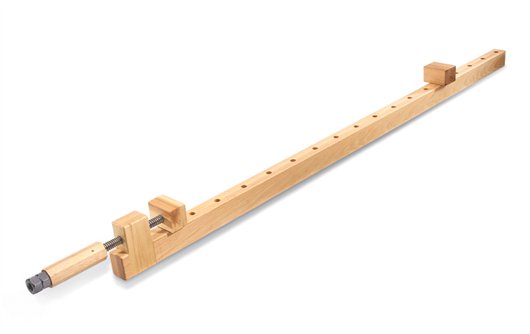

Wooden Bar Clamps

Shop-made clamps that deliver versatility and performance.

By Dave Olson

|

End your clamp shortage once and for all. These wooden clamps are easy to make, a joy to use and they exert plenty of clamping pressure. If you build them with scrap lumber, they cost less than half the cost of a comparable aluminum bar or steel I-beam clamp. So why not turn what would be an ordinary purchase into a fun shop project? You can make these clamps in any length; the ones shown here have a |

You may also like…7 Classic Ways to Store Clamps Space-Saving Clamp Rack Universal Clamp Rack |

Durable Acme ThreadsDesigned for use in vises and machine tools, Acme threads are wide-bodied for strength and steeply inclined to efficiently transfer clamping pressure. They’re faster to adjust than standard V-threads, because they have fewer threads per inch. They’re also less likely to clog with debris. |

Click any image to view a larger version. |

Versatile HandleIt’s easy to grip by hand and long enough for two-handed tightening. Locked nuts on the end accommodate a drill for speed or a wrench for extra torque. |

Three-Position JawThe offset post creates different clamping points for fast setup and maximum adjustability. For storage, simply plant this jaw in the hole nearest the headstock and secure it with the headstock jaw. |

No Black StainsThese wooden clamps won’t mar your workpiece or leave unsightly stains, the way steel or iron bar clamps can. An easy-to-apply shellac and wax finish keeps glue from sticking. |

Stable On Any SurfaceThanks to their flat-bottom design, these clamps won’t tip over, even when they extend well beyond the edge of your bench. They also work great on sawhorses. |

Add Some ComfortFor Comfort and increased gripping power, wrap the handle like a tennis racket, using rubber cut from an inner tube. Simply stretch the rubber around the handle and tuck or tape the ends. This story originally appeared in American Woodworker September 2005, issue #116. |

Purchase the complete version of this woodworking project story from AWBookstore.com. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.