We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Editor’s note: Bryant documented his move process on his Instagram account, of which I have been a follower for a long time. I asked him to write a blog post to share his thoughts in a longer format. Enjoy! – David Lyell

You’ve been putting it off for months, you knew it was coming. Perhaps the lease is up on your shop, or you bought a new house with a nice detached garage. Maybe you built a nice pole barn on your property. No matter the category you fall into, shop moves are stressful! Being fresh off the move train myself, I have a few tips and tricks that I have learned to keep your turn around time short and sweet. And maybe a few things that might save you some green!

A solid game plan is the key to success. The difference in a well thought out, well-executed plan vs. a hip-fired, fly by the seat of your pants plan can make a world of difference. If you wait until your friends show up on a Saturday morning to finish packing, you are making it hard on yourself and your well-mannered buddies. I keep my shop lean, so it usually takes me a week to pack, however, if you are a wood hoarder, or your machinery isn’t mobile, you should plan to take an extra week or two.

A solid game plan is the key to success. The difference in a well thought out, well-executed plan vs. a hip-fired, fly by the seat of your pants plan can make a world of difference. If you wait until your friends show up on a Saturday morning to finish packing, you are making it hard on yourself and your well-mannered buddies. I keep my shop lean, so it usually takes me a week to pack, however, if you are a wood hoarder, or your machinery isn’t mobile, you should plan to take an extra week or two.

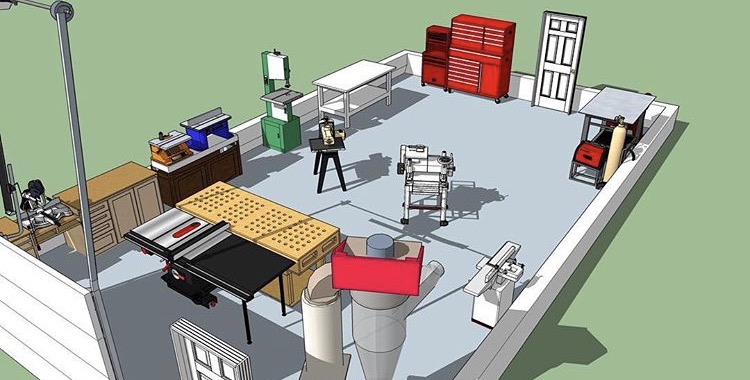

Before you even move into the new space, take some time to actually dimension out placement of machinery and overall workflow. This small time commitment will ensure that come moving day, you can direct your volunteers to place things in a manner that they will stay. The last thing you want to do after your help leaves is try to move everything yourself! There are a few resources available to assist in shop planning. I use SketchUp for all my client designs and it makes planning to scale simple. If you aren’t tech savvy, don’t worry! Go check out Grizzly Industrial’s Woodshop Planner on their website. This tool is simple to use and makes it easy to at least get a general plan together.

Let’s talk about electrical. Did you run receptacles? Did you put in light fixtures? Are they staying or going? These are some questions that you should ask during your initial planning stages. If you plan on leaving your electrical and lighting, then disregard what I’m about to write. I personally ran all my electrical and lighting so it all got pulled out when it was time to turn in my keys. I was lucky enough to surface mount all my boxes and run MC cable. Some guys love conduit, but in my opinion, MC is far easier and faster than trying to bend EMT conduit and fish wire, MC has already done that for you! I typically cut the cable at the point it terminates into the box, inspect it for any cuts or defects, spool my cable up and reuse in the future. If you plan on reusing boxes, make sure you tidy them up! There is nothing worse than trying to run new receptacles in your space and having to cut out the old wire or wire nuts. The more prep you do before you move, the easier it will be to set up!

Organization is something that will save you hours of shop set up time. I have all of my handtools and smaller power tools in two large rolling tool chests. I took the time to label all drawers so I don’t have to hang things on pegboard in the new space. The best part of this method is that no matter where you go, you have some familiarity in where things are. Believe me, you will be digging though enough bins looking for odds and ends, the last thing you want to do is throw your delicate (and expensive!) marking tools and hand planes in a bin or a box and expect them to work perfectly after. Invest in good tool storage so you can guarantee your tools work after you move them.

Lastly, teamwork makes the dream work, BRING ON AS MANY PEOPLE TO HELP AS POSSIBLE. If you have ten pairs of hands to help lift and move, the overall work effort is far less than if you only have two pairs. Take the time to plan out everything to the last detail. Pack smart! And remember, leave the space in better shape than when you got there.

– Bryant Todd

Camille Woodworking

Find Camille Woodworking on Instagram and YouTube.

Bryant Todd is the sole proprietor of Camille Woodworking out of Columbus, OH. He specializes in clean lines, handwork and details. He started Camille Woodworking in 2012 and named after his mother who was diagnosed with Early Onset Alzheimer’s Disease. Every piece made is a testament to her. They make everything from cutting boards to tables, knick knacks to credenzas.

Bryant Todd is the sole proprietor of Camille Woodworking out of Columbus, OH. He specializes in clean lines, handwork and details. He started Camille Woodworking in 2012 and named after his mother who was diagnosed with Early Onset Alzheimer’s Disease. Every piece made is a testament to her. They make everything from cutting boards to tables, knick knacks to credenzas.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.