We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

3 Tips to Unlock its Beauty

by Tom Caspar

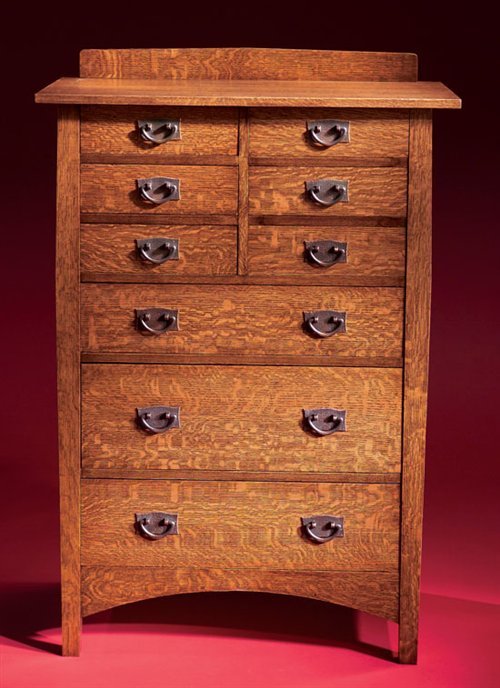

Boldly displaying spectacular quartersawn figure can turn an ordinary project inotoa blue-ribbon winner. Here are three ways a professional cuts oak so legs, panels and the top all contribute to a grand effect.

|

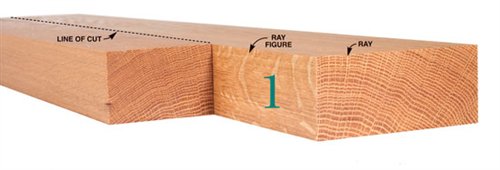

Rip Quartersawn Legs

With the right cut, you can make beautifully matching quartersawn legs from an ordinary 2-in.-thick board. The flake figure we look for in quartersawn oak comes from a tree’s ray cells, which radiate like spokes in a wheel. Mark the spot on each end of your board where a saw cut will be parallel to the rays. Cut from mark to mark. Rip quartersawn veneer from another piece of the same board and glue it on the legs’ plainsawn faces to complete the quartered look (see “Stickley-Style Chest”).

|

|

|

Edge a Top

On many a piece of furniture, both the top and its front edge are prominent. Unfortunately, a beautiful quartersawn top has an ordinary-looking plainsawn edge. An easy solution is to cut your own quartersawn edging from the same lumber and glue it to the top’s edge. The edging can be from 1/16 to 1/4 in. thick. Apply similar edging to drawer rails and dividers. |

|

|

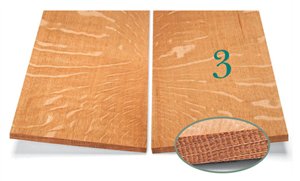

Resaw a Panel

Quartersawn boards are rarely wide enough for a large panel, so in many cases you must glue boards together or resaw and book-match a single board. Here’s a rule of thumb for resawing quartersawn oak: Look at the outside faces before you cut. If both sides have strong flake figure, the inside faces will have dramatic figure, too. If one outside face has weak figure, the inside faces probably won’t be great. The best board to pick for resawing will have perpendicular growth rings (see inset photo). |

|

This story originally appeared in American Woodworker September 2005, issue #116.

Source information may have changed since the original publication date.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.