We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

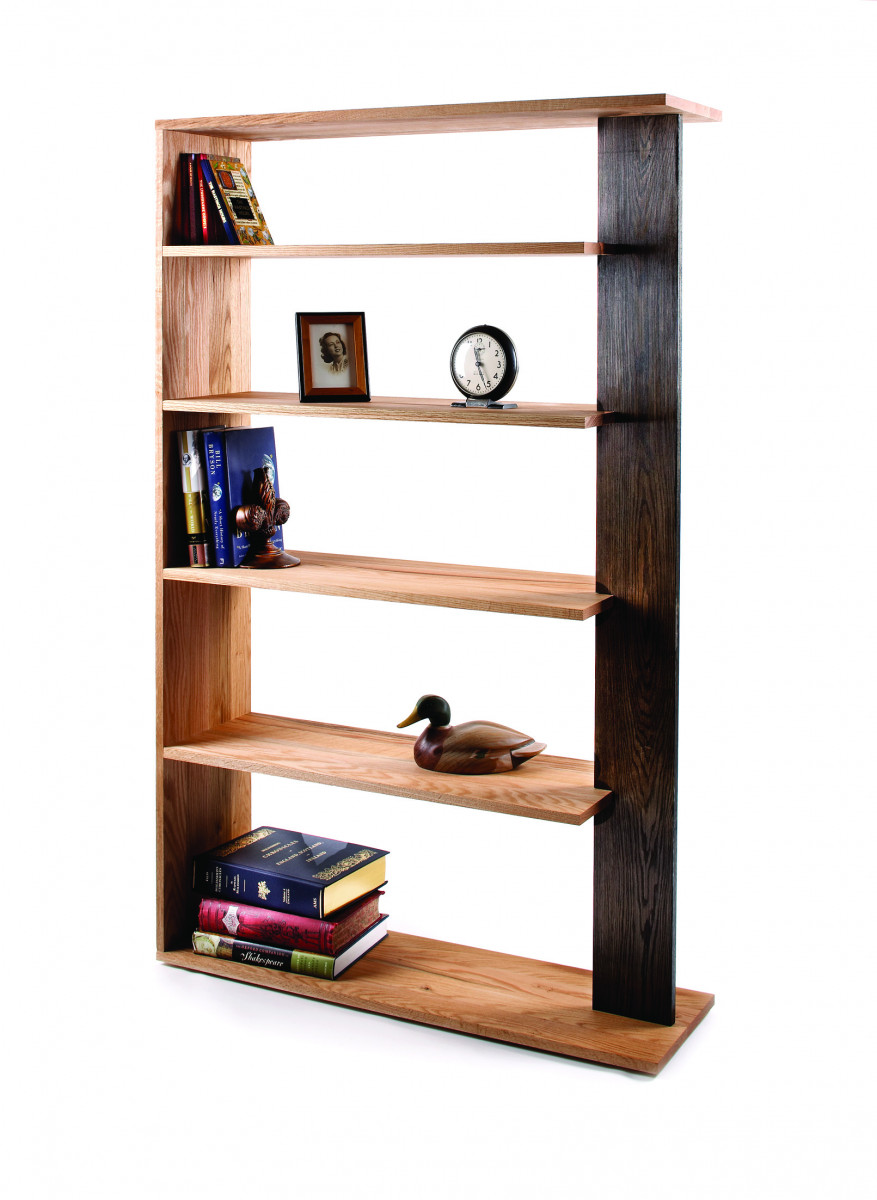

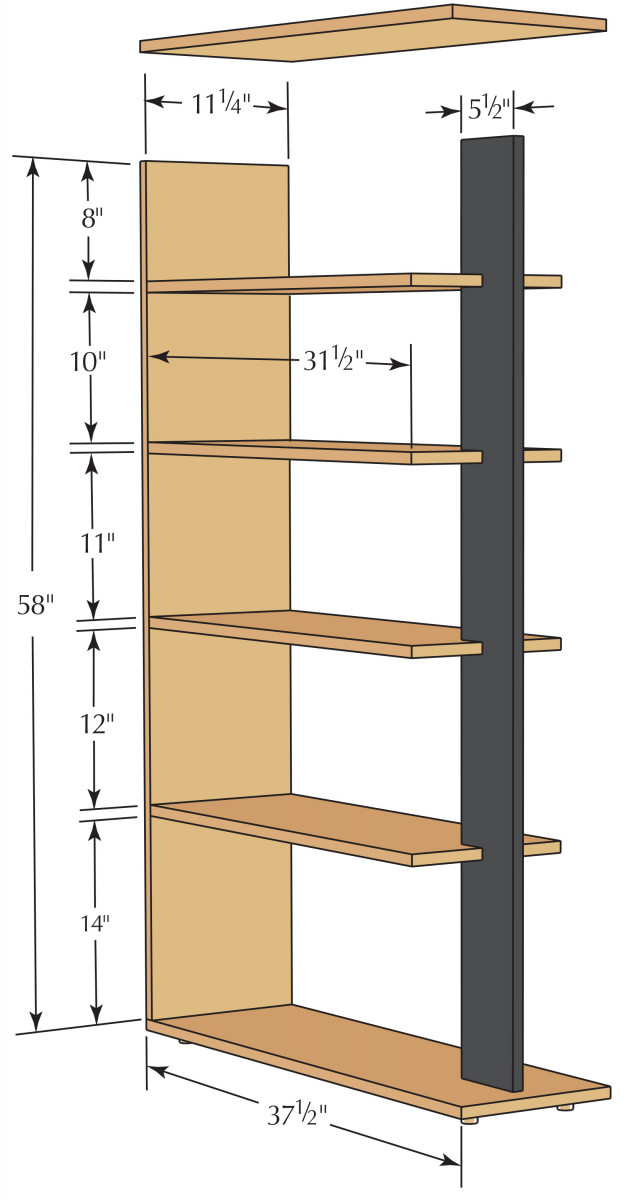

Two-toned appeal. Different colors of wood, simple lines and sharp, square edges give these easy-to-build bookshelves a contemporary flair.

Two tones of color and sharp, square edges give this piece modern flair.

Inspired by a design in the February 2008 issue of the German magazine Selbst, this “I Can Do That” project commenced (as always) with a pilgrimage to the home center, where I picked up four 6′ 1x12s and one 6′ 1×6 of red oak, and a bag of red oak plugs.

Because there are no curves and no long rip cuts, this piece is ultra-simple to build. The trickiest operation is notching out the upright that will be stained black … and that’s not tricky at all.

It’s always a good idea to ensure the ends of your boards are square, so first trim a small amount off one end of all your pieces at the miter saw, and mark the cut ends.

Now you’re ready to get started. Set up a stop 311⁄2” to the left of the saw blade as shown in the picture on the next page. Butt the trimmed end of one 1×12 against the stop, cut your first shelf, then repeat three times.Move the stop to 371⁄2” and cut the matching top and bottom pieces. Your final crosscuts are on the two side pieces, at 58″ (again, butt the ends you’ve trimmed against the stop so that both ends will be square after the cuts).

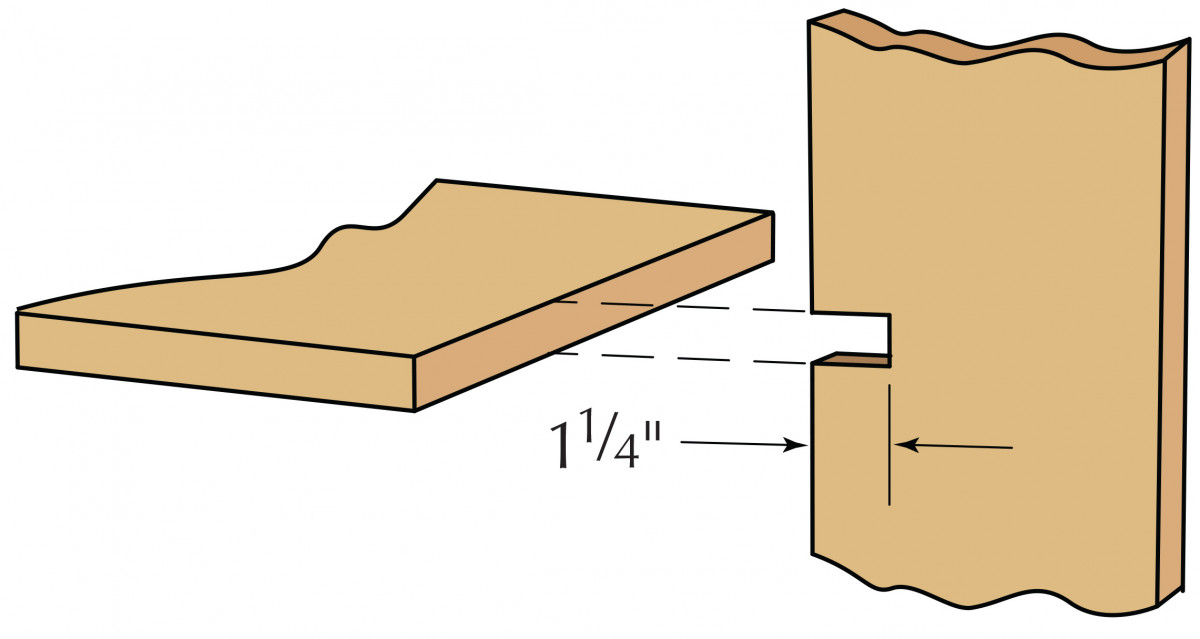

Lay the 1×6 (which is actually 5 1⁄2” wide) flat and mark the four notches for the shelves. Theoretically, each notch should be 3⁄4” thick (the thickness of your stock), but because you still need to sand the shelves, you may want to cut the notches a hair under that – or sand all your pieces to #120 grit first, and use the final thickness as your marking guide. Each notch is 11⁄4” deep, marked per the drawing.

Now clamp the 1×6 flat to your Workmate and use a jigsaw to cut out the notches. To minimize blade deflection, use a heavy blade for the 11⁄4“-deep cuts, then switch to a fine, narrow blade to make the 3⁄4” cuts at the end of each notch. You may have to use a rasp to clean up the cuts after jigsawing, as you need them to be flat on all sides, and fit snug to the shelves.

Clamped stop. Making multiple cuts of equal length at the miter saw is made easier by measuring just one piece then clamping a stop-block to the fence. Then, instead of measuring and marking each cut, you can simply butt the squared stock against the stop.

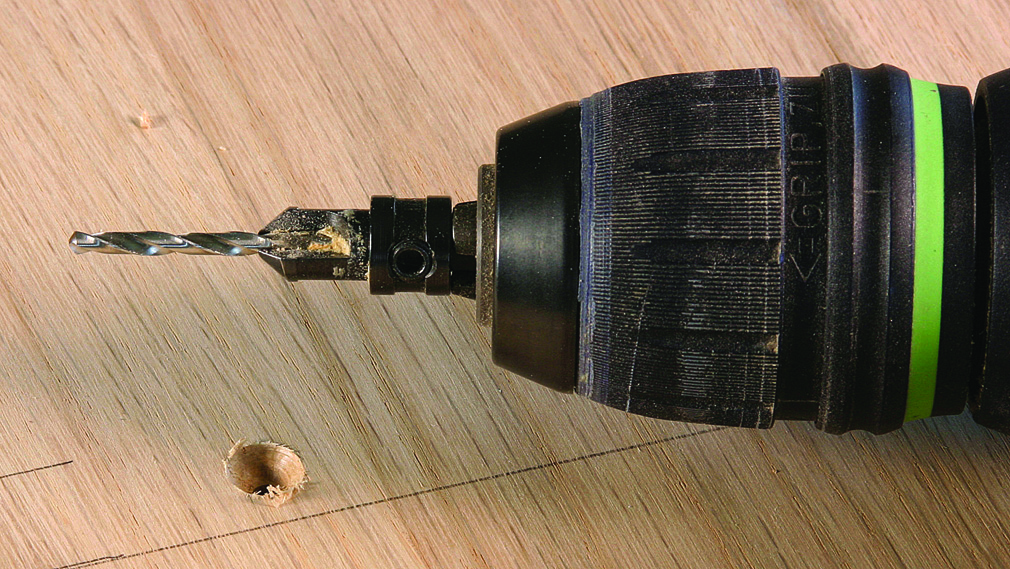

Lay the notched side piece atop the interior face of the wide side piece with the top and bottom aligned, then mark the notch locations on the wide side to show the location for the screws. Set the notched piece aside. Use a combination square to mark the shelf lines across the wide piece and mark for three screw holes across each shelf location. Drill the clearance holes with a 1⁄8” bit, then flip the piece over. Using your already drilled holes as a guide, drill countersinks at each hole location on the outside face.

Now find a flat surface on which to rest one end of the wide side piece, then clamp a shelf into your Workmate and lay the side piece across it (interior down), carefully lining up the shelf with the lines you’ve marked on the side. The side piece serves as a location guide to drill 1⁄8” pilot holes into the shelf. Now sink 13⁄4” screws into each hole, securing the shelf to the side. We recommend McFeeley’s or Spax “premium” wood screws; both are available at mcfeelys.com or 800-443-7937.

Attach the remaining three shelves in the same manner. (You may need help to reposition the workpiece as you add the shelves; it gets heavier with each one.)

After the four shelves are attached, lay the piece on its side on a table (shelves pointing up), and scoot it to the end of the table so you have room to easily manipulate your drill. Balance the top piece at the top edge, and drill three pilot holes through the top and into the side. Then drill countersinks into the pilot holes in the top, and set the screws. Do the same at the bottom.

Line up the notched side at the center, drill two pilot holes and countersinks at the top and bottom, and set the screws.

Countersink bit. The top of this countersink bit drills a hole with angled sides, into which a screw head seats so that it’s flush with or below the surface of your work, depending on how deep you drill the countersink.

Once you’re sure everything fits together well, remove the notched piece and finish as desired. I used two coats of Cabot’s ebony stain. After the stain was completely dry, I reinstalled the notched side, glued and tapped in plugs to cover the screw holes on top and sanded them flush, then finished the entire piece with two wiped-on coats of Watco Danish Oil in natural.

Unless your notches are very snug, you’ll need to “toenail” the shelves from the undersides to the notched side piece, to keep each shelf firmly in place. (Toenailing is simply a nail set at an angle through two pieces.)

Finally, make four 1″ x 1″ feet out of pieces of scrap (I used 1⁄2” plywood) and nail them to the bottom, about 1″ in from the corners.

A final note: With any heavy and tall piece, it’s necessary to secure it to the wall before loading it up.

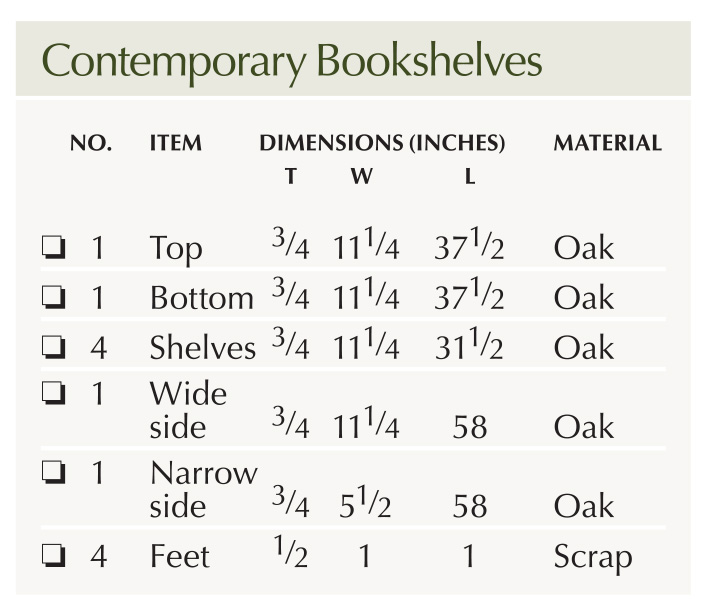

Contemporary Bookshelves Cut List

Contemporary Shelves

Notch detail

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.