We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

|

|

|

Tired of working on a sheet of plywood thrown over a pair of

sawhorses? Had it with rolling benches that wiggle and wobble? Hate

running around your shop whenever you need a tool? Boy, do we have the

bench for you. Our dream bench starts with traditional workbench

features like a thick top, a sturdy base, bench dogs and a pair of

vises. Then we added tons of storage, an extra-wide top, and modern,

cast-iron vises. Last but not least, we devised a simple method to make

the bench mobile and still provide a rock-solid work platform. Our

bench is built to withstand generations of heavy use. Simple, stout

construction absorbs vibration and can handle any woodworking procedure

from chopping deep pocket mortises to routing an edge on a round

tabletop. The thick, butcher-block-style top is truly a joy to work on.

We'll show you how to surface this huge top without going insane trying

to level 24 separate strips of glued-up hardwood. Our top doesn't waste

wood—even the offcuts are used.

Benefits:

|

Tons of easy-access storage: |

Extra-wide, heavy-duty top: |

|

You name it, this bench can clamp it down: |

It's rock-solid but mobile: |

|

PHOTO 1: |

PHOTO 2: |

|

PHOTO 3: |

PHOTO 4: |

Tools & Materials

If you go all out like we did you can expect to pay about $900 for

materials. If you can't swing that much dough all at once, don't worry;

you can build an equally functional version for about $450. How? Save

$220 right off the bat by substituting common 2x4s for the maple top.

We made several tops this way and they work great. Just be sure you dry

your 2x4s to around 8-percent moisture content before you build. You

can save $75 by skipping the expensive birch plywood and hardwood. Just

stick with construction lumber. The inexpensive bench may not look as

classy, but hey, it's still a great workbench. You could build

adjustable shelves inside the cabinets instead of drawers and pullout

trays. They're less convenient, but it'll save you another $110 in

drawer slides.The best thing is you can cut costs and still get a fully

functional bench right away, even if you go with the least expensive

options. When you've got the extra cash, you can always build the maple

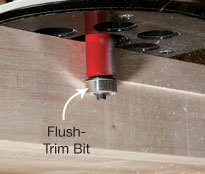

top or add the full-extension hardware. To build the bench you'll need

a tablesaw, planer, belt or orbital sander, a router and a circular

saw. You'll also want a flush-trim bit and a dado blade for your

tablesaw.

|

PHOTO 5: |

PHOTO 6: |

Build the Cabinet

Cut the plywood parts for the three individual boxes (Parts D and E)

and assemble them (Photo 1). The three boxes are joined to form the

cabinet (Photo 2). Screw the two end pieces of birch plywood (H) to the

cabinet, placing the screws where the face frame will cover them (Fig. A).

Cut the plywood top (C) according to the actual measurements of your

assembled cabinet and attach with screws. Do the same for the back (B).

Cut and assemble the three face frames (parts U through AA). Use the

actual measurements of your cabinet to determine rail lengths. The face

frames are built slightly oversize to give you a little wiggle room

when gluing them to the carcase. The extra overhang will get trimmed

off later. Clamp and glue the side frames first. Tack the frames down

with a couple of brad nails so they don't scoot around under clamping

pressure. Use a flush-trim bit and a router to trim the side frames

even with the plywood. Attach and trim the front face frame (Photos 3

and 4). To mount the drawer and pull-out shelf slides, turn the cabinet

on its back and use a square to mark centerlines. Use a simple T-square

jig to align the slides so the screw holes are on the line (Photo 5).

|

PHOTO 7: |

PHOTO 8: |

|

PHOTO 9: |

PHOTO 10: |

The Top

This is the business end of your bench. You'll want to take extra care

in each step to ensure a flat, solid top. Start by rough-cutting your

top stock (EE) to length (Photo 6). Cut 3/4 in. x 3/4-in. dadoes for

the bench dog (JJ) into the edge of one of the top pieces (Photo 7).

Before you start to glue up the top, make use of the offcuts. Just end

glue them in a line to create a full-length piece (Photo 8). I know

gluing end grain is a no-no, but all you want here is to hold the

pieces together long enough to build them into the top. Each segmented

piece will get properly edge-glued to other full-length pieces. The

result is a strong top that doesn't waste precious hardwood. Here's how

to assemble the butcher-block top without facing a sentence of hard

labor sanding. Glue up three 12-in. sections of the top on a flat

surface. We flipped the cabinet face down and used the back for our

glue-up (Photo 9). Each 12-in. section should start and end with a

full-length piece.

|

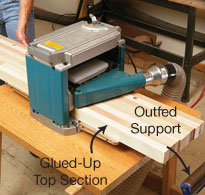

PHOTO 11: |

PHOTO 12: |

The segmented pieces can alternate with full-length pieces. Once the

glue is good and dry (overnight is best), remove the top section from

the clamps and scrape off any squeeze out. Now you're going to put your

portable planer to the test. Each section gets planed down to 2-1/2-in.

thickness (Photo 10). Take light cuts for the sake of your planer, and

to minimize tear-out. Try wetting the top's surface before the last

pass for the smoothest possible cut. Some minor tear-out is inevitable

with a big glue-up like this. Remember it's a workbench, not a museum

piece. Once all three sections are surfaced, you can glue them together

(Photo 11). Do one at a time. This allows you to concentrate on keeping

each joint perfectly level. Before you use any glue, dry clamp your

sections to make sure the clamps can draw the joint tight. Even a

slightly bowed section will be hard for clamps to pull straight. (See

Oops!, below, for a nifty fix.) Once all the sections are glued

together you'll need to trim the ends to final length. Mark the ends of

the top with a square. Continue the marks around the underside of the

top as well. Set a circular saw for a 1-1/2-in.-deep cut and clamp a

straightedge to the top so the saw cuts on the line. Make the first

cut. Then flip over the top and set the straightedge for the second

cut. Complete the cut and smooth the ends with a power sander.

|

PHOTO 13: |

PHOTO 14: |

Build the Base

Build the base flush with the bottom of the cabinet. Pick the

straightest 2x4s you can find for the frame. If possible, we recommend

starting out with 2x6s that have been dried to about 8-percent moisture

content. Then joint and plane them to make straight and true 2x4s.

Assemble the 2×4 frame with screws. A plywood base top (A) is fastened

to the frame to finish the base.

If your bench is going to be stationary, go ahead and shim the base

level before adding the cabinet. If you want to make a mobile bench,

attach the six casters to the underside of the plywood base's top (Fig. A).

Leave just enough room for the casters to rotate freely inside the 2×4

frame. Six casters allow the bench to glide smoothly, even if your

floor is uneven. Add the base molding to finish the bench (Photo 13).

Doors, Drawers & Pull-Out Shelves

Start by cutting three door blanks (J). Add the 1/2-in.-birch edging on

all four edges. Put a 3/8-in. round-over all the way around the outside

edge of all three blanks. On the tablesaw or router table, cut a 3/8

in. x 3/8-in. rabbet on all four inside edges. Crosscut the drawer

fronts (K, L and M) out of one of the blanks and use the other two for

doors. Build and mount the drawers and pullout shelves according to (Fig. C)

Now all that's left is to secure the top to the cabinet (Photo 14).

Accommodate the expansion and contraction of the solid-wood top by

elongating the two outside holes on the angle-iron cleats under the top

(Fig. A). A simple oil finish completes the job. There, now you've got all the support you'll ever need for your woodworking.

Download Plywood Cutting Diagram

Oops!

It's possible for the edges of the laminated top sections to end up

with a slight bow. With 12 in. of width, you're not likely to

straighten them out with clamp pressure. So what should you do?

A jointer is out of the question; the 12-in. section of top is just too

big and heavy, even for two people. We used a simple two-step process

with a router and a straightedge to joint our bowed top section.

|

Step 1: |

Step 2: |

Sources:

Home Center, Four sheets 3/4" AC fir plywood, $27 ea. ($108 total), One

sheet 3/4" birch plywood, $37, Three 8' 2x4s, $3.50 ea. ($10.50 total),

9 ft. 1-1/2" x 1-1/2" angle iron, $1.50 ea. ($14 total).

Wall Lumber Co., (800) 633-4062, 90 bd. ft. 8/4 soft maple, $3 ea. (total $270), 25 bd. ft. 3/4" birch, $3 (total $75).

Woodworker's Hardware, (800) 383-0130, Ten 24" full-extension drawer

slides with 1-in. overtravel, KV8405 B24 ANO, $11 ea. ($110 total) Two

3/8" inset, self-closing hinges, A07128 3, $1.50 ea. ($3 total), Six 3"

swivel-plate industrial casters, rubber, $10 ea. ($60 total)

Five 2" birch knobs, SBKR 200, 75¢ ea. ($3.75 total), 1/2" x 1-1/2"

straight cutter, CMT812.627.11, $17, 1/2" x 1-1/2" flush-trim bit,

CMT806.629.11, $21.

Highland Hardware, (800) 241-6748, 9" quick-release vise, 199152, $100,

7" quick-release vise, 199151, $70. Grand total: $899.25.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.