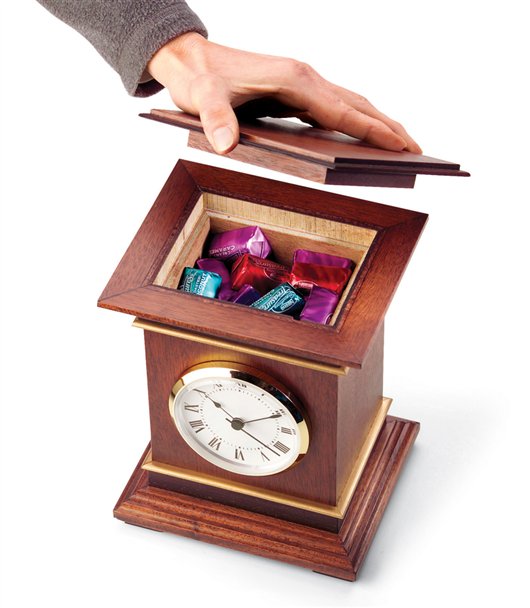

This clock holds a secret—a compartment

for candy—and its construction involves a few

secrets as well.Such as this: The case is made from 1/2″-thick

mahogany plywood. You won’t find this material

at most lumberyards, so you’ll be making

your own by gluing together two layers of 1/4″

plywood.

Another secret: You’ll be gluing the moldings

to the plywood case first, then mitering the parts

later. This simplifies the building process and

sure beats mitering all the moldings individually.

Tools and materials

To build this clock, you’ll need a tablesaw,

a planer, a router table and a drill

press. You’ll be using a couple of special

router bits: a classical bead and cove

bit and a 1/8″ roundover bit. You’ll also

need an adjustable circle cutter to cut

the round clock opening (see Sources, below).

The clock is made from Honduras

mahogany plywood and lumber, with

some wenge trim. Wenge (pronounced

wen-gay or wenj) is a dark-brown tropical

hardwood that nicely complements

mahogany’s reddish-brown color.

For the clock case, you’ll need 1/4″-

thick mahogany plywood. It doesn’t take

much, so buy a partial sheet unless you

plan to make several clocks. You’ll also

need a 3/4″ x 6″ x 48″ piece of mahogany

lumber and a chunk of wenge. Buy a

piece of wenge that’s at least 3″ wide

by 32″ long. It’s more than you actually

need, but it’s easier and safer to cut the

parts from a piece this size, rather than

from one that’s smaller.

The battery-powered clock mechanism

is a one-piece insert (see Sources),

which is simply friction-fit into a hole

in the clock front. This makes it easy to

change the batteries or the time.

Laminate the plywood

Cut two 32″ x 8″ pieces of 1/4″ mahogany

plywood (Fig. B, below). Notice

that the grain runs the short dimension

on these parts. Glue these together

to form the 1/2″ mahogany plywood

needed for the clock case (Photo 1).

After the glue has dried, rip the 1/2″

plywood to 7-1/2″ wide on the tablesaw.

Take about 1/4″ off both edges so

they are straight and parallel. Next, cut

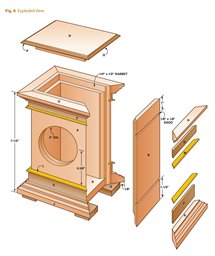

the two 1/8″ dadoes in the face of the

plywood (Photo 2, Fig. A, page below).

Attach moldings

and trim

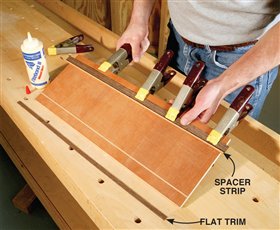

Make the upper and lower flat trim

pieces (C, D, E and F). Place spacer

strips in the small dadoes in the panel

to provide a stop for the flat trim to

push up against, and glue the flat trim

to the 1/2″ plywood panel (Photo 3).

Remove the spacer strips before the

glue dries to prevent them from getting

stuck.

Next cut a strip of mahogany for the

top and bottom moldings (G, H, J and

K). Use the bead and cove router bit to

shape them (Photo 4). Note that the

top molding is 1/8″ thinner than the

bottom molding and they are attached

to the plywood so they mirror each

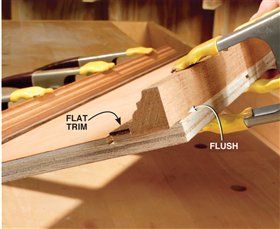

other (Fig. A). Glue and clamp them to the plywood (Photo 5). The edges of the molding

and the plywood should be flush. If they’re not, wait

until the glue has dried and trim the parts flush on

your tablesaw. Complete the 1/2″ plywood panel by

cutting a rabbet at the top and bottom on the back

side (Photo 6, Fig. A).

Miter the sides

Set your tablesaw blade to 45° and miter some test

boards. Then use a tablesaw sled—or a miter gauge

with a fence—to miter the clock’s four sides. Start by

cutting the sides about 1/4″ oversize (Photo 7). It’s OK

to leave the extra material on one edge; it will be cut off

when you cut the parts to final width (Photo 8). Cut

slowly to avoid chip-out on the moldings. Wenge is

particularly prone to chip-out, but cutting at a slower

rate helps avoid that problem. If the wood does chip,

save the loose piece and glue it back on. Use a toothpick

to apply the glue and masking tape to hold the

chip in place.

Drill the opening for the clock insert into the clock

case front (A, Photo 9). The clock insert is centered

vertically on the case front between the two gold halfbead

trim pieces (L).

Assemble the case

Apply glue to two sides first and hold them together

with masking tape. Add the other two sides one at

a time. Stretch the tape, so it pulls the parts tightly

together (Photo 10). Then glue in the bottom and add

the four feet (S, Photo 11).

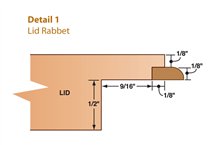

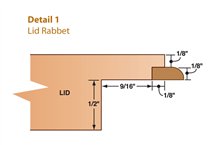

Next, make the lid (N). Cut the rabbets on the bottom

of the lid (Detail 1). Check that the lid fits easily

into the rabbet in the top of the clock case.

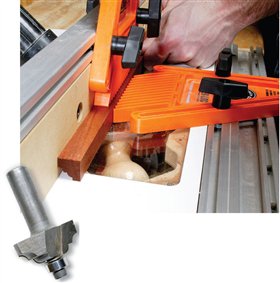

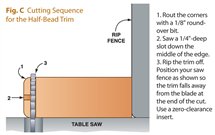

Make the half-bead trim (L, M, P, Q) that goes

around the case and the lid. This trim is very small,

but is easy to make using our step-by-step cutting

sequence (Fig. C, below). Miter the half-bead trim

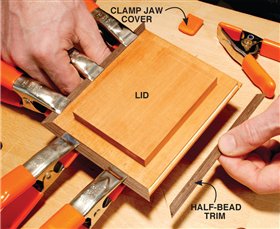

that goes around the lid and attach it to the underside of the lid (Photos 12 and 13). You’ll

need some small spring clamps to hold

these trim pieces in place while the glue

dries (see Sources). Set aside the strips

of half-bead trim (L, M) that go around

the case. They will be used later.

Finishing touches

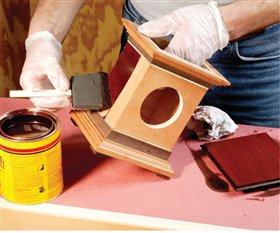

Sand the entire clock case and lid with

180-grit paper and stain it (Photo 14).

A red mahogany stain gives the mahogany

a deep rich tone and helps even

out any color difference between the

plywood and the lumber (see Sources).

After the stain dries thoroughly

(24 to 48 hours), brush on a satin polyurethane

varnish (see Sources).

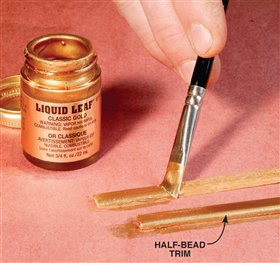

While the stain and finish dry, paint

the half-bead trim gold (L and M,

Photo 15). Miter it to final length and

glue it into the dadoes on the clock case.

All that’s left now is to install the battery

in the clock mechanism, set the time

and insert the mechanism into the clock

case (Photo 16).

Oh yeah, don’t forget to add the

candy.

Sources

(Note: Product availability and costs are subject to change since original publication date.)

Woodworker’s Supply, woodworker.com,

800-645-9292, Adjustable heavy duty circle

cutter, #829-757; 1″ spring clamps, #125-

033.

MLCS, mlcswoodworking.com, 800-533-9298,

1/4″ classic bead and cove router bit, #6452; 1/8″ round-over router bit, #6350.

Rockler Woodworking and Hardware, rockler.

com, 800-279-4441, Decorator clock face,

#23995.

Jo-Ann Fabric and Craft Stores, joann.com,

888-739-4120, Plaid liquid leaf classic gold,

#5766563.

Woodworkers Source, woodworkerssource.

com, 800-423-2450, 3/4″-thick wenge.

Wood & Shop Inc., woodnshop.com, 314-739-

0001, Mahogany plywood 1/4″ x 2′ x 4′.

Minwax, minwax.com, 800-523-9299 (for

dealer locations), Satin fast-drying polyurethane,

#63000; Red mahogany

stain, #70007.

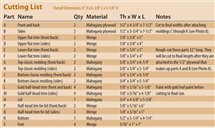

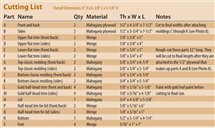

Cutting List

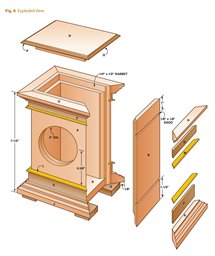

Fig. A: Exploded View

Detail 1: Lid Rabbet

Fig. B: Plywood Cutting Diagram

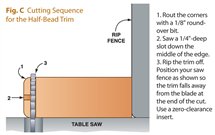

Fig. C: Cutting Sequence for the Half-Bead Trim

1. Rout the corners

with a 1/8″ roundover

bit.

2. Saw a 1/4″-deep

slot down the

middle of the edge.

3. Rip the trim off.

Position your saw

fence as shown so

the trim falls away

from the blade at

the end of the cut.

Use a zero-clearance

insert.

This story originally appeared in American Woodworker July 2004, issue #108.

|

|

Click any image to view a larger version.

1. Make your own 1/2″ mahogany plywood for the clock case,

because finding it at a lumberyard can be difficult. Use several

bricks as clamps and a piece of cardboard to protect the

plywood from getting scratched.

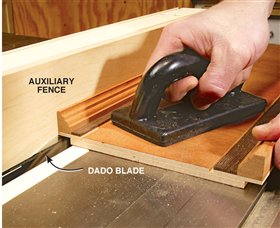

2. Cut two 1/8″ dadoes in the face of the plywood panel. A thin

molding that goes all the way around the clock will later be fit

into these dadoes. Use a push block for safety and to maintain

even pressure while sawing.

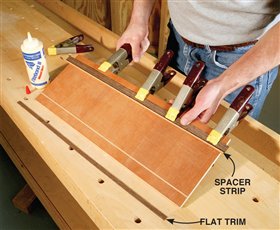

3. Glue and clamp the flat trim pieces onto the plywood panel.

Put a 1/8″ x 1/4″ spacer strip into the dadoes (without glue)

and push the flat trim up against it. Remove the spacer strip

after you’ve attached the clamps.

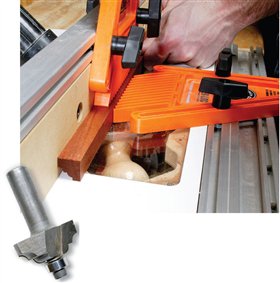

4. Rout the top and bottom moldings with a

classical bead and cove router bit. Use feather

boards to hold the molding against the fence

and table for the smoothest cut.

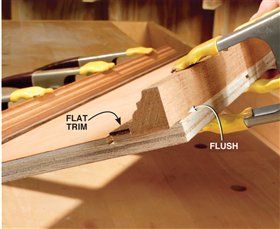

5. Glue and clamp the classic molding tight against the edge of

the flat trim. The molding’s outer side should be flush with the

plywood edge. Trim off any molding or plywood overhang with

your tablesaw.

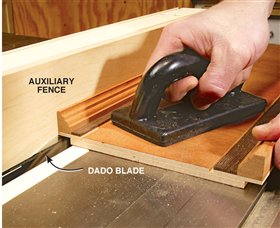

6. Cut two rabbets in the plywood panel for the lid and bottom.

Put a temporary wooden auxiliary fence on your saw so you can

push the fence right up to the dado blade.

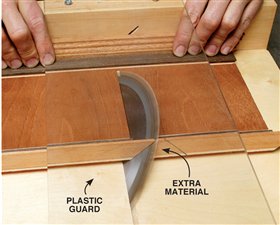

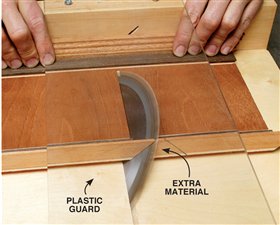

7. Cut one miter on all four case sides with a shop-made sled. Cut

the sides a little extra wide at this step. Pushing more slowly

than normal helps reduce chip-out on the moldings.

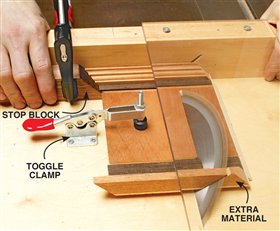

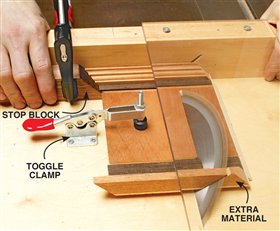

8. Miter the sides to final width. Hold each piece in place with a

toggle clamp. This ensures a straight cut and keeps your hands

out of harm’s way.

9. Drill the hole for the clock with a circle cutter. Set the drill press to its

slowest speed and hold the part with two toggle clamps. Secure the

backer board to the drill table with a couple of clamps.

10. Assemble the sides with glue and masking tape. Pull the masking tape

tight and check for gaps along the miters.

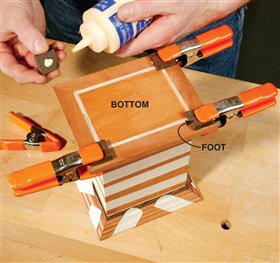

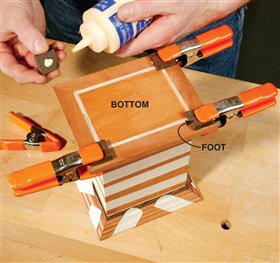

11. Glue the bottom into the rabbet that runs around the sides.

Attach the feet 1/8″ in from the edge of the molding.

12. Miter the half-bead trim using a small handsaw and a jig. The

jig is simply two mitered boards glued to a piece of plywood.

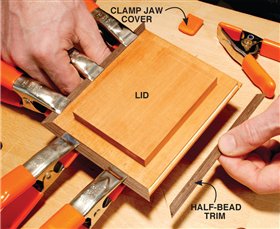

13. Glue the half-bead trim into the small rabbet on the bottom

side of the lid. Remove one of the jaw covers from the spring

clamp to provided more pressure on the small trim. Leave the

other jaw cover on to protect the lid’s top from getting dented.

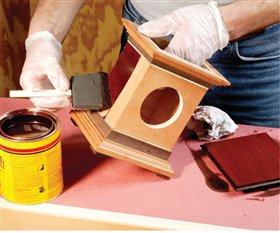

14. Stain the clock case to even out any differences in wood color

between the solid lumber and plywood parts. When the stain

is dry, apply a clear finish.

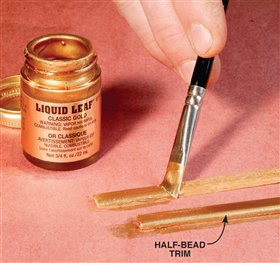

15. Apply three coats of gold paint to the half-bead trim that

goes around the clock case. Sand between coats to remove

any roughness. Install the trim after the paint is dry.

16. Install the clock mechanism. It’s simply a pressure fit, requiring

no fasteners. |