Hidden within a few trees in every forest lies a mysteriously

distorted wood that has always fascinated

woodworkers.You can’t spot curly wood from the outside, but inside

the tree a peculiar switch has been flipped, turning straight

tree cells into wavy cells. Cut the tree open, plane the

wood and you get spectacular, three-dimensional rippling

wood grain.

But beauty comes at a price.You can tear your hair out

trying to tame this unruly wood.Here are some practical

tips on how to buy,machine and finish curly wood.

What Is Curly Wood?

The stripes you see in a finished board of curly wood

come from the play of light on grain that waves from side

to side (Photo 1). The troughs and crests of the waves

reflect light in different directions. As you turn a curly

board around in your hands, its surface actually shimmers.

Light areas turn dark and dark areas turn light.

The biology of curly wood is as mysterious as its appearance.

No one really understands why some trees have

this wavy grain. It’s not genetic.You can take seeds from a

curly tree,plant them near their parent and get nothing but

straight-grained timber. The best guess is that stressful

growing conditions, such as cold and drought, turn on the

curly switch in a few trees,but no one has figured out how

to duplicate these conditions in order to grow curly trees.

Curly grain can appear and disappear within a single

tree. One side of a tree can be curly, and the other side

straight. Young outer layers may be curly, but not older

inner layers. It’s totally baffling!

Buying Curly Wood

Any kind of tree can become curly,but

some species that grow in tough northern

climates produce a greater percentage

of curly wood than others

(Photo 2). Flame birch and tiger maple

are well-known examples, but you can

uncover curly walnut, curly cherry and

curly oak, just to name a few.

If you’re lucky, you can find curly

wood in any pile of lumber for the same

price as a straight-grained board.Many

lumber mills process logs so fast they

don’t stop and cull the unusual curly

ones. If you search for curly boards in

the rough, look for a striped barberpole

surface or alternating areas of

smooth and fuzzy grain.

A few folks in the lumber trade make

it their business to find curly logs.Wood

prospectors mine for curly gold in the

hundreds of average trees felled by a

lumber mill.The prospectors peel back

the bark of some logs before they’re

sawn.If they hit pay dirt,they’ll purchase

the log and gamble that most of it is

truly curly.No one will really know how

spectacular or faint the curl is until it’s

sawn.

Each dealer has their own system of

grading curly wood, based both on

general figure and the number of curls

per inch.They’ll be the first to tell you

that curly wood is so unusual that it

defies classification. Your best bet for

consistency is to stick with a dealer

who has a large stockpile and familiarity

with this enigmatic wood.

The Benefits of Wide Boards

Many dealers in curly wood hoard

wide stock.Their logs are custom sawn

to maximize the width of each board.

Why go to so much trouble? Imagine

a drawer front made of three curly

boards glued together. Individually,

each board looks fantastic, but they

don’t work together (Photo 3). One

wide board for the drawer front would

look much better. Experienced builders

of reproduction furniture look high

and low for wide boards.

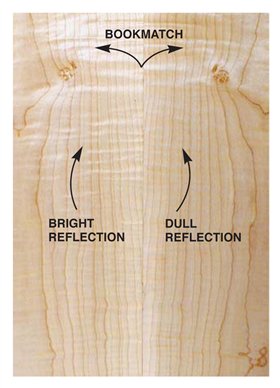

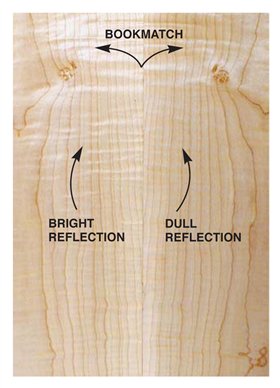

Bookmatching

If you resaw and bookmatch curly

wood, light can play tricks on you

(Photo 4). Sure, you’ve made a wide

board with mirror-image grain (the

physical structure of the cells),but look

what happens to the figure (the surface

appearance of the cells).The grain runs

uphill on one side of the board and

downhill on the other.

What does that do to the figure?

One side of the board can be light, the

other side dark. Shift your viewpoint

and the brightness shifts the other way.

Again, a wide board may be a better

choice. Musical instrument makers

routinely bookmatch the curly wood

they call fiddleback maple, but they’re

awfully picky about selecting just the

right boards.

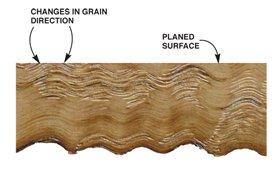

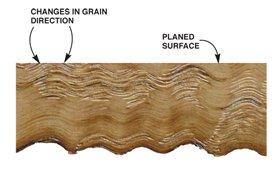

Reducing Tear-Out

Curly boards are notoriously difficult to joint and plane,but

armed with some woodworking savvy you can usually produce

a blemish-free surface.The problem is the grain,which

changes direction with every ripple (Photo 5). It runs downhill

on one side of a wave and uphill on the other side. So no

matter which way you feed a board, whole hunks of wood

can be yanked off the surface by a machine’s knives, leaving

an ugly pit behind. If you’ve just spent a pile of money on

some special wood, this can be heartbreaking.Here’s how to

minimize tear-out:

– Change your knives. Dull knives on a jointer or planer

pull on wood grain; sharp knives cut it cleanly.

– Take a light cut. Set your machine to remove 1/64 to 1/32

in. at a time. Sure, you’ll take many more passes, but you’ll

minimize the depth of any tear-out.

– Wet the wood. Green wood is easier to cut than dried

wood, because wet cells are easier to separate and less likely

to pry out their neighbors.You can temporarily achieve the

same effect on kiln-dried wood by lightly sponging the surface

of a board before you joint or plane (Photo 6).Give your

jointer bed a good waxing and the board won’t drag. Rest assured, you won’t rust your cutter heads as long as you

clean and dry them right away.

– Feed slowly. Go slow on the jointer, about half the

speed you normally use.

– Scrape, don’t plane. If you’re working with hand tools,

use a No. 80 scraper plane (#03.12.05; $33 from Highland

Hardware, 800-241-6748). Its steep cutting angle allows

you to quickly remove milling marks without any fear of

tear-out. A card scraper is the perfect tool for smoothing

small areas of shallow tear-out.

Despite your best efforts, a little tear-out when working

curly wood is inevitable. Don’t get too discouraged. Some

curly boards are so wild that even the finest woodworkers

turn to two more tools: drum sanders and putty. A drum

sander is a surefire (and expensive) way to surface curly

wood perfectly smooth. It’s slower than a jointer or planer,

but you’re guaranteed a clean shave. For tiny pits of tear-out

that run pretty deep,use putty. If you scrape or sand down

to the bottom of the tear-out you might end up creating a

whole new problem: a shallow, dished out divot.You may

not see it right away, but it’ll show up under a finish.

Finishing Tips

The amount of color in a finish can make a big difference in

bringing out the curl. The explanation lies in looking once

more at curly wood’s grain structure.Remember how the surface

of a flat board cuts right through the rising and falling

grain? When the grain rises up to the surface it exposes the

ends of many cells. These end-grain cells are thirsty to

absorb a finish, just like the end grain of any board. But the

side-grain cells on the crests and troughs of each wave don’t

absorb as much finish. The result is that some areas of a

board soak up more finish (and color) than others.

Finishes such as shellac, oil and varnish are slightly colored.

The thirsty parts of a board soak up an extra amount

of this color. This extra color really makes the curl pop.

Orange or amber shellac has more color than blond shellac,

making the effect particularly striking (Photo 7).

Other finishes such as lacquer and waterborne

polyurethane don’t have much color in them.You can still see

the curl under them,but it’s not as dramatic. However, if you

apply these finishes over a coat of dewaxed shellac you can

have the best of both worlds.

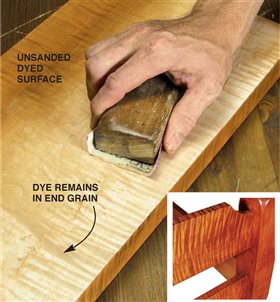

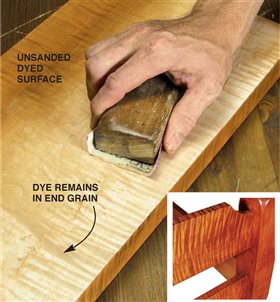

Dyeing Curly Figure

Here’s a neat trick using dyes instead of stains to emphasize the dark

figure of curls. This is a shop-tested recipe to simulate the look of

antique curly maple furniture:

1. Sand your maple to 220 grit and apply one coat of Dark Mission

Brown water-soluble dye,mixed 1/8 tsp.powder to 1 cup water. Let dry.

2. Re-sand with 220 grit paper. Sand until the wood surrounding

the dark-colored curls is light.

3. Apply Early American water-soluble dye mixed 1/2 tsp. powder

to 1 cup water. Let dry.

4. Apply a liberal amount of boiled linseed oil.Wipe off the excess

after 30 minutes. Let dry at least three days.

5. To further warm the color of the wood and give it an aged look,

apply a burnt umber glaze.Visit the Web site listed below for more on

using glazes.

6. Apply your favorite topcoat. If you’re using a waterborne finish,

apply dewaxed shellac first.

Sources

(Note: Source information may have changed since the original publication date.)

Homestead Finishing Company, homesteadfinishing.com, 216-631-5309, Water-soluble dyes:

Dark Mission Brown, #3274, and

Early American Maple, #3273, $7.25 for

1 oz.;

Japan color:

Burnt Umber, #7002, $6.25 for 8 oz.

This story originally appeared in American Woodworker February 2002, issue #92. |

|

Click on any image to view a larger version.

1. Split open a curly log and you’ll find grain that

bends back and forth like a wave. Planing the wood

cuts through the waves, producing a shimmering effect

like light bouncing off the ripples on a pond.This chunk

of white oak is spectacular-looking wood!

2. Curly wood is found in every kind of tree under the sun.

Environmental factors probably turn normal trees into curly

ones, but nobody knows for sure how it happens. Soft maple and

birch are the most common domestic curly woods.

3. Glued-up curly boards may not

go well together. Curly figure is

unusual because it runs at right angles

to the edge of a board. It’s difficult to

align figure like this in a group of narrow

boards. Instead, look for wide boards.

4. Resawing a curly board into two

bookmatched pieces makes a wide

panel, but you may not like what you see.

Although the grain structure is the same

in both boards, the figure doesn’t look

the same. Bright areas on one side may

look like dull areas on the other side.

5. The planed surface of a curly board slices right

through the waves of grain. Making a curly surface

smooth and free of tear-out is pretty tricky, because the

grain constantly changes direction. Half the time you’re

actually cutting against the grain!

6. Wetting the surface of curly wood before jointing or

planing virtually eliminates tear-out.This may be hard to

believe, but temporarily softening the fibers really works!

7. Finishes that are slightly colored emphasize the curls

more than perfectly clear finishes.Amber shellac has an

extra amount of color, enhancing the effect.

8. Dye penetrates deeply into the thirsty end-grain

areas of the curls. It makes them stand out from

the surrounding wood. For even more contrast, sand

the board.The curls remain dark while the surrounding

wood stays light.Then, apply a second coat of dye.

|