We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Glass for Woodworking

By Brad Holden

Once you delve into the world of glass, you may find there’s

no turning back. Glass is a versatile material. When you want

to display a cabinet’s contents, a glass door panel lets your

favorite china, glassware or collectables shine. Stained or textured

glass, also known as art glass, can add a bright visual element on a

piece of furniture. The choice of colors is practically endless.

Textured glass can be etched or sculpted. The patterns

range from geometric to impressionistic.

Glass is often used for shelves in display cabinets. Glass

shelving allows light to pass through and better illuminate

the entire cabinet interior. They eliminate the hard shadows

cast by wood shelves.

Glass is a good choice for a tabletop when the base is

the focal point. If you’ve poured your heart and soul into

a beautiful base, you

don’t want to bury it

under a solid wood top.

This story will introduce

you to the basics of

selecting and buying

glass for your projects.

We’ll review the different

types of glass, edge treatments

and thicknesses so

you’ll know what to ask

for when you walk into

your local glass supplier.

Plate Glass Vs. Tempered Glass

|

Plate Glass We’re most familiar with this type of glass . Plate glass is available Art glass is often 1/8-in. plate glass. Textures or patterns |

Click any image to view a larger version. |

|

Tempered Glass Tempered glass can take a hit. It has twice the impact resistance of plate glass. Tempered glass costs twice as much as plate glass. It must be special |

Plate glass shatters When tempered glass |

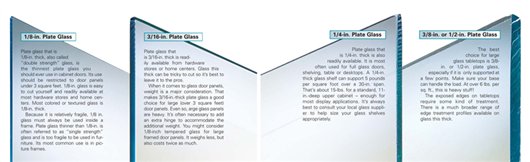

Choose the Right Plate Glass Thickness

Choose an Edge Treatment

|

Cut glass has sharp, rough edges that |

Sources(Note: Product availability and costs are subject to change since original publication date.) Glass Source for Woodworkers, theglasssource.net, Outwater Plastics Industries, Inc., outwater.com, 800-631-8375. Ed Hoy, edhoy.com. Spectrum Glass, spectrumglass.com, 425-483-6699. Wissmach Glass Company, wissmachglass.com, 304-337-8800. Kokomo Opalescent Glass, kog.com, 765-457-8136. Your Local Yellow Pages, under Glass, stained and leaded. (Outwater and Think Glass sell directly to the public. This story originally appeared in American Woodworker July 2007, issue #129. |

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.