We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

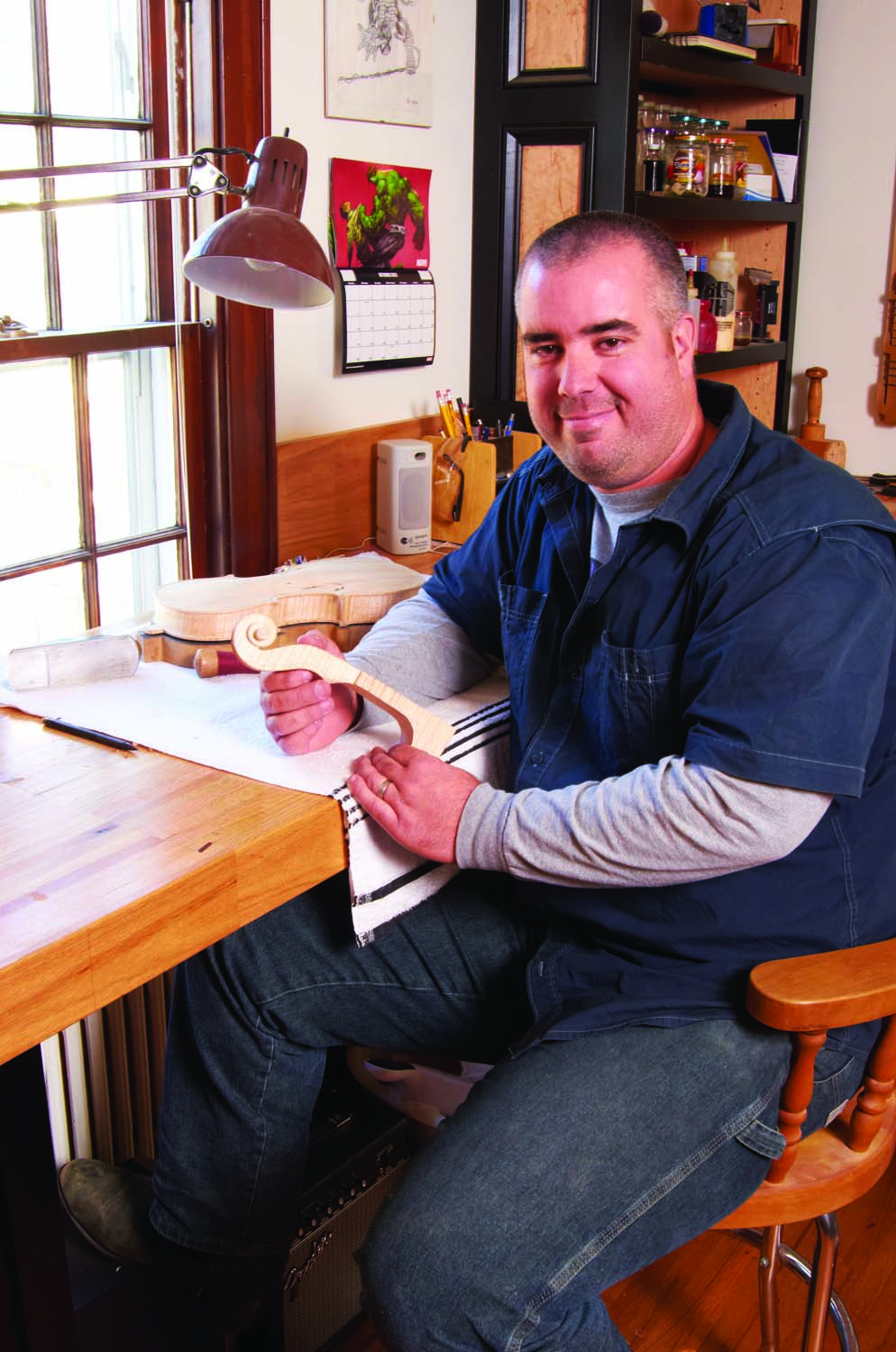

My shop is located in a spare bedroom. As a luthier, I don’t need a lot of space—just enough to allow working on a double bass. What I do need, though, is storage for lots of small parts, tools, patterns, etc. Before moving to this space, I drew designs and configurations for chests, drawer stacks, hutches and benches in a variety of different forms, but when I saw Dr. Warren Kragt’s “Ginormous Shop Cabinet” in American Woodworker, it shouted, “I’m the cabinet you’ve been looking for!”

My shop is located in a spare bedroom. As a luthier, I don’t need a lot of space—just enough to allow working on a double bass. What I do need, though, is storage for lots of small parts, tools, patterns, etc. Before moving to this space, I drew designs and configurations for chests, drawer stacks, hutches and benches in a variety of different forms, but when I saw Dr. Warren Kragt’s “Ginormous Shop Cabinet” in American Woodworker, it shouted, “I’m the cabinet you’ve been looking for!”

So, I modified the dimensions to suit my needs and tweaked the design for both stability and appearance. Having many small parts and tools, I knew I would make good use of shallow drawers. But I really had to think about what I was going to store in them to determine how shallow or deep they should be and how many I could fit in the cabinet while keeping its proportions close to the original design.

At first I dreamed of storing all of my tools in the cabinet, but ultimately, I decided to install a second cabinet under the bench to keep the chisels, gouges, rulers and other hand tools that I use the most frequently close at hand. I also decided to add a desktop hutch to store things that wouldn’t fit well in drawers, such as varnishes, rosins, touch up brushes, pigments and the hot plate I use to heat up bridges and hide glue, as well as reference materials and parts catalogues. Lastly, I installed a wall rack and to keep my most commonly used clamps, hammers, Japanese saws and scrapers easily accessible.

I changed the cabinet’s structure from frameless to face-frame for increased rigidity. I used walnut for the frame and birds-eye maple for the side panels—I ran across a piece of 3/4″ maple ply at my local big box store that had birds-eye covering its back face. A lucky find! I ebonized the walnut because I like the “ebony/ maple” look. I think it goes with the violins. The drawer fronts are made from curly maple that I “rescued” from work (a cabinet shop where we don’t use figured wood). Each drawer front is banded with ebonized walnut. The drawer boxes are made of hard maple and dovetailed. I added a few “secret” compartments, and now I’m torn whether or not to tell people about them, lest they don’t remain so secret.

The best way to find what works is through use. In my previous shops my bench was always at desk height, but for this shop I decided to raise it so I could sit at a barstool. However, after many long days at this bar-height bench, I’ve decided that desk height—and a comfortable chair—has its advantages. So, I’ve decided to reconstruct the bench to include a lower section. That means I’ll have to build another, lower, drawer stack—with wider drawers, to remedy a painful oversight in the original. It seems no matter how careful the planning, something always shows up that won’t fit in any drawer! –Mark Hollerud Austin, Minnesota

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.