We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

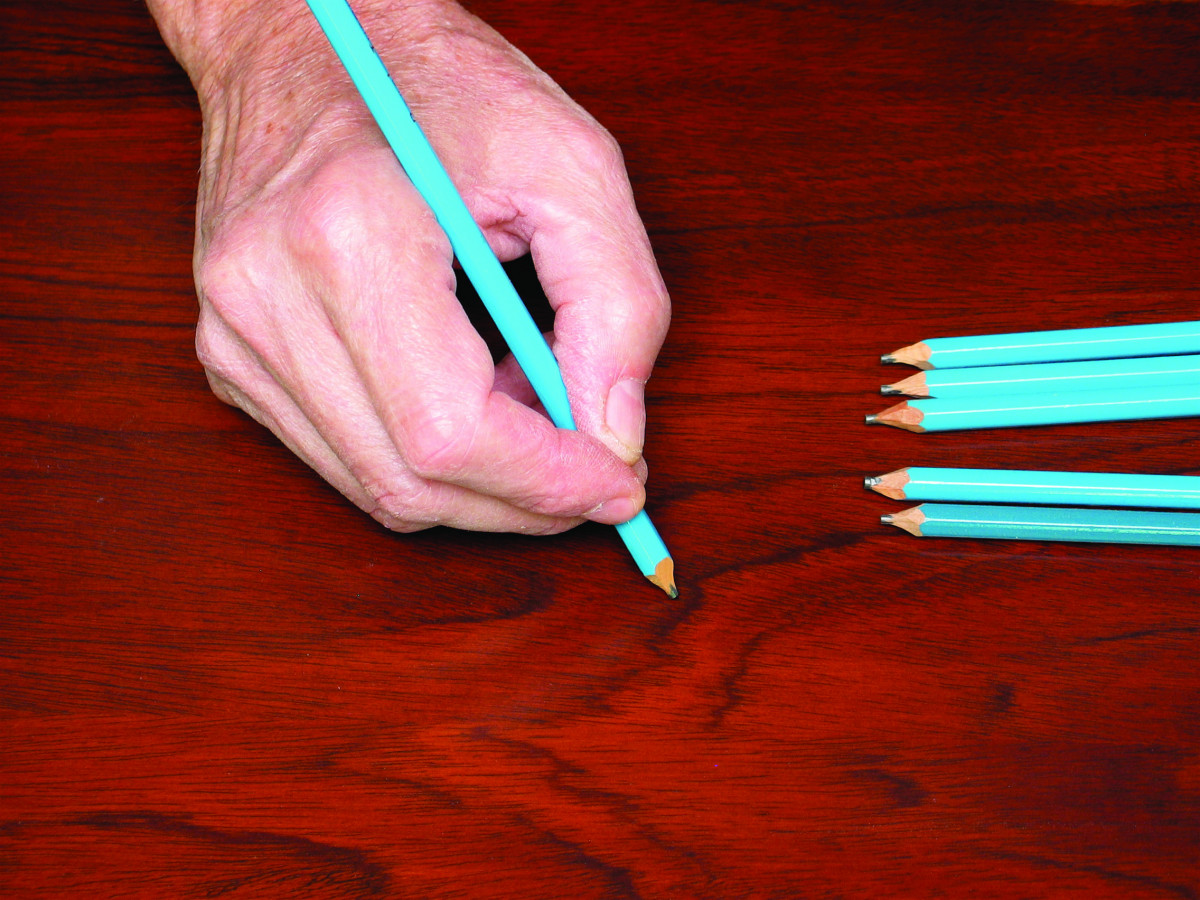

To determine the relative scratch resistance of a finish, push the sharp edge of the cylindrical lead in various “B” and “H” architect’s pencils forward on a finish. There’s no need to use pressure. The next-to-hardest pencil that doesn’t scratch the finish is the rating for that finish.

A few sample boards can save you from future finishing headaches.

Finish manufacturers targeting the furniture industry and large professional finish shops provide a lot of information about their products. Unfortunately, the manufacturers who target amateur woodworkers and small shop professionals aren’t as helpful.

In the end, we are often left to our own devices to figure out the characteristics of the finishes we are buying.

Here are some easy tests you can perform in your shop to determine the qualities of the finishes you’re using. In most cases you’ll want to do the tests on scrap wood. For the most accurate results, let the finish cure at least a couple weeks in a warm room before performing the tests.

Scratch Resistance

The ability of a finish to resist damage from coarse or sharp objects is likely one of the most important qualities about which you’re concerned.

To a large extent you can know the comparative scratch resistance simply from the type of product. For example, oil-based varnishes (including polyurethane varnish) and catalyzed lacquers are much more scratch resistant than shellac and nitrocellulose lacquer, and a little more scratch resistant than acrylic and polyurethane water-based finishes.

But what about differences among brands within each finish type? Or what about the comparative difference between a water-based polyurethane and an oil-based polyurethane – that is, how much scratch resistance are you actually giving up by using a water-based polyurethane?

To determine a finish’s scratch resistance, purchase a set of architect’s drawing pencils ranging in hardness from about 2B (soft) to 5H (hard). Sharpen each pencil using a knife so you leave the sharp cylindrical edge of the lead intact. If you damage this edge, or if it becomes worn, sand it flat, holding the pencil 90° to the sandpaper.

Beginning with one of the softer pencils, hold it as you would for writing and push it forward across the cured finish. Maintaining equal pressure, follow with pencils of increasing hardness until you find one that cuts into the finish. The hardness rating for that finish is the rating of the previous pencil – the hardest lead that doesn’t cut.

Water Resistance

The relative water resistance of a thin finish can be determined by placing a small puddle of water on the finish and covering it to prevent evaporation. Check at regular intervals for damage.

Another quality you may be looking for in a finish is water resistance. A thickly applied finish of any type is very water resistant. So testing won’t be very revealing except on thin finishes such as oil or wax, or any film-building finish applied with just one or two coats.

To test for water resistance, make up a sample board with the same number of coats applied in the same manner as on your project. Then place a small puddle of water on the surface and cover it with a small metal or glass cup or jar to prevent evaporation. Check every 10 minutes or so until you notice cracks or discoloration in the finish. Rate the finish at the most recent previous time before the damage occurred.

The most vulnerable surface to water damage is the top edge of cabinet doors just below a sink. To test this surface, stand a finished sample door on a sponge lying in a pan of water. Check the finish around the edge every so often until cracks appear in the finish, the finish delaminates, or there is some discoloration that you can observe.

Heat Resistance

Whether or not a finish is resistant to dry heat can be determined by placing a pot of hot water on a finished scrap board. Heat the water to just short of boiling and leave it for an hour. See if it causes any damage.

Resistance to damage from hot objects is a very important quality for table and counter surfaces in kitchen and dining areas. Again, finish types tell you something. For example, oil-based polyurethane and catalyzed lacquer should pass almost any test. But shellac, lacquer and water-based finish will likely be vulnerable. There are two tests for heat resistance you can do at home.

To test for dry heat resistance, place a metal cup or pan containing water heated to just below boiling on a cured finish. Remove the cooled container after one hour and look for splits, indentations or discoloration in the finish.

To test a type of finish for wet heat resistance, do the same as above but this time place a cotton cloth or cheesecloth wetted with the same hot water under the cup or pan. After an hour, check the surface for splits in the finish or discoloration.

Chemical Resistance

Many household substances can cause damage to a finish. To check the resistance of the finish you’re using, place a number of drops of the substance, in this case ketchup, on the finish and sponge them off one at a time several minutes apart.

Eating surfaces are also vulnerable to staining from a number of household liquids independent of the thickness of the finish. In other words, the finish itself may become stained. Common products that can cause a problem include vinegar, orange juice, lemon juice, grape juice, ketchup, mustard, coffee, tea, wine and 100-proof alcohol. (You can use denatured alcohol mixed half with water instead of liquor for the alcohol test.)

To test a finish for resistance to each of these liquids, place a number of drops on the finish and sponge them off one at a time at short intervals (generally several minutes apart) until the finish under the drops becomes dull, discolored, shows cracks or the wood underneath becomes stained.

The resistance of the finish to damage from these liquids is rated at the last time before the damage appeared.

Yellowing

To determine the color of a finish, and thus the relative amount of color change it will add to the wood, pour a little of several finishes into jars and place them next to each other against a white background. Here I’m comparing two wiping varnishes. Waterlox is much darker and will make wood significantly darker than Minwax’s Wipe-On Poly.

Yellowing can be a good or bad quality depending on the situation. Generally, darker woods and darker-stained woods look good under a finish that yellows because the yellowing makes the wood appear warmer. But yellowing often detracts from lighter woods or from woods that have been stained or “pickled” white or near white.

Acrylic water-based finishes don’t yellow at all. Polyurethane water-based finishes yellow a tiny bit. Varnishes and oil/varnish blends yellow significantly, but the degree of yellowing will vary greatly among brands. Lacquers also vary among types and brands.

There are two tests you can perform in your home to determine the yellowing characteristics of various finishes. The first is for the color of the finish in liquid form and the second is for how much the finish continues to yellow as it ages.

To test for the color of a liquid finish, pour some into a glass jar or onto a glass plate and hold the glass against something white such as a piece of paper. It’s easy to compare finishes when you place the test jars or plates next to each other.

To test for the amount a finish yellows as it ages, apply a coat or two to a piece of white plastic. After the finish has cured, cover part of it with paper or masking tape and leave the plastic in a normal room setting or in a window for several weeks.

Every few days remove the paper or masking tape and compare the color of the covered and uncovered parts.

Keep in mind that most woods darken with age, so some of the “yellowing” you may see after application to wood could be associated with it rather than the finish.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.