We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

No wood finish illustrates better than “teak oil” why finishing is so confusing. Brands vary from mineral oil, to linseed oil, to tung oil, to oil/varnish blend, to wiping varnish, to simply wax and turpentine.

Many brands claim or imply ultraviolet resistance. But my tests, and the experiences of many in the wooden-boat community, contradict this. From a technical standpoint, these finishes are applied too thin to be effective, even if manufacturers have actually added UV absorbers.

Some brands claim to be formulated specifically for teak and other oily woods, but they don’t dry better, which is what you would want for an oily wood that retards the drying of oils and varnishes. Others claim to “feed” the wood or replace natural oils, which is silly. No wood needs feeding, and teak’s natural oily resin can’t be replaced.

Commercially available teak oils are all over the map with their claims. One truth that can be said about them all is that none has anything to do with teak wood or teak trees. Teak trees aren’t drained of their oily resin to make teak oil.

Here’s some background about “oil” finishes. Twenty-five years ago, I wrote an article in Woodwork Magazine attempting to make sense of the many wipe-on finishes sold as oil. These included raw and boiled linseed oil, tung oil, oil/varnish blend and thinned varnish (not oil at all) that I called “wiping varnish.”

Due primarily to manufacturer mislabeling, there was tremendous confusion in woodworking circles. I spent most days for three months testing products and even had some examined by a chemist trying to figure out what they were. It turned out to be pretty simple, of course, and you probably have a good understanding now because, even though few manufacturers have mended their mislabeling ways, most writers and teachers have adopted the vocabulary and definitions I suggested.

Defining Terms

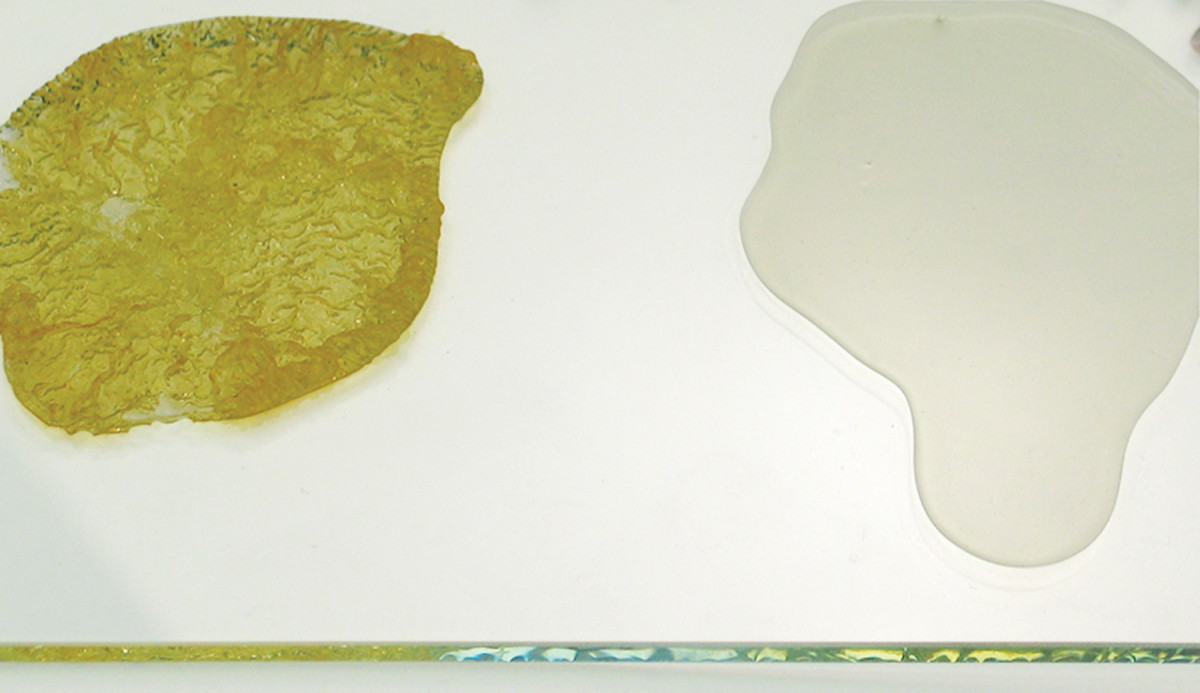

Identification test. To determine if an unknown finish that thins with mineral spirits or turpentine is oil or varnish, put a puddle on a non-porous surface such as glass or the top of the can and see how it dries. If it dries soft and wrinkled (left), it is a drying oil such as linseed oil or tung oil, or a mixture of one of these oils and varnish. If it dries hard and smooth, (right), it is varnish. If it doesn’t dry, it is some type of mineral oil.

Linseed oil and tung oil cure soft and wrinkled unless all the excess is wiped off after each coat. These finishes are sold as “raw linseed oil,” (which dries too slowly to be useful as a wood finish), “boiled linseed oil,” “100% tung oil” and “teak oil.”

Mixtures of linseed oil and/or tung oil and varnish (including polyurethane varnish) also cure soft and wrinkled (though harder than linseed oil and tung oil) unless all the excess is wiped off. I named these finishes “oil/varnish blend.” They are sold under a wide variety of names, including Antique Oil, Maloof Oil, Danish oil, tung oil and teak oil.

All these finishes could be grouped under the broad term “oil” because they are applied and dry the same, and all the excess has to be wiped off to be functional. Otherwise, the surface will be sticky for a long time.

Wiping varnish is the outlier among the wipe-on finishes marketed as oil because wiping varnish cures hard after a number of hours. Therefore, it can be left wet to dry so that several coats create a build. The greater the build, the better the protection for the wood against all types of moisture. This finish is also sold under a wide variety of names, including Wipe-On Poly, Seal-a-Cell, ProFin, salad bowl finish, tung oil and teak oil.

Notice that all of these finishes( except linseed oil) are sold as tung oil and teak oil, which accounts for a lot of the confusion. Real tung oil does exist, but teak oil doesn’t.

Teak

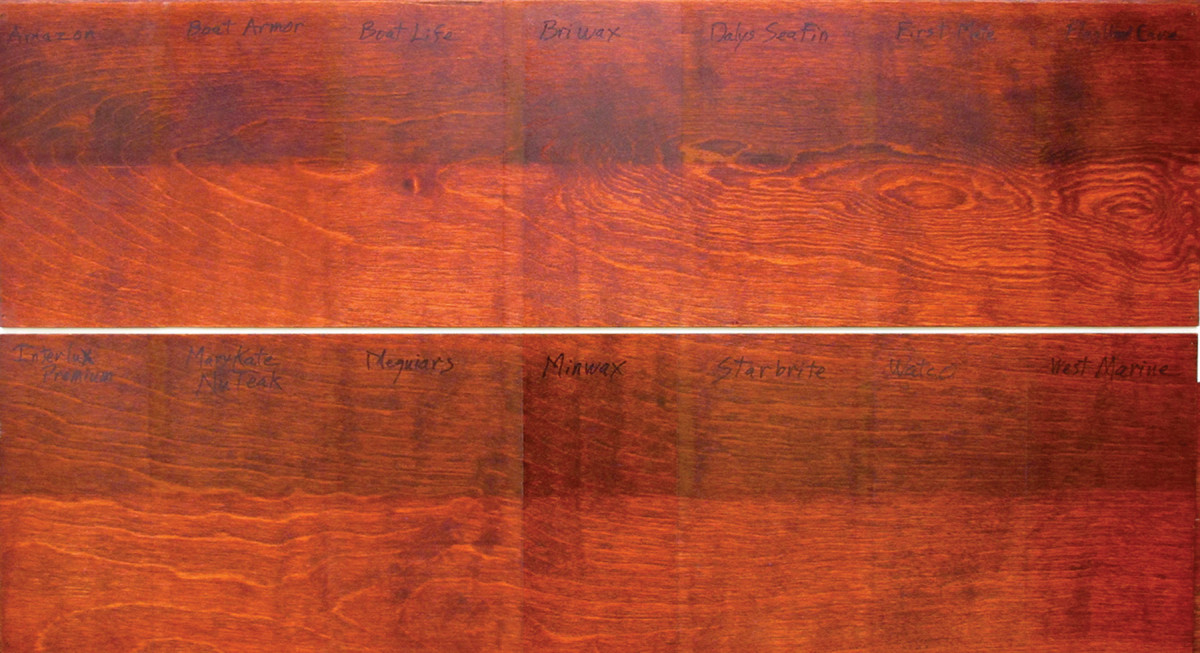

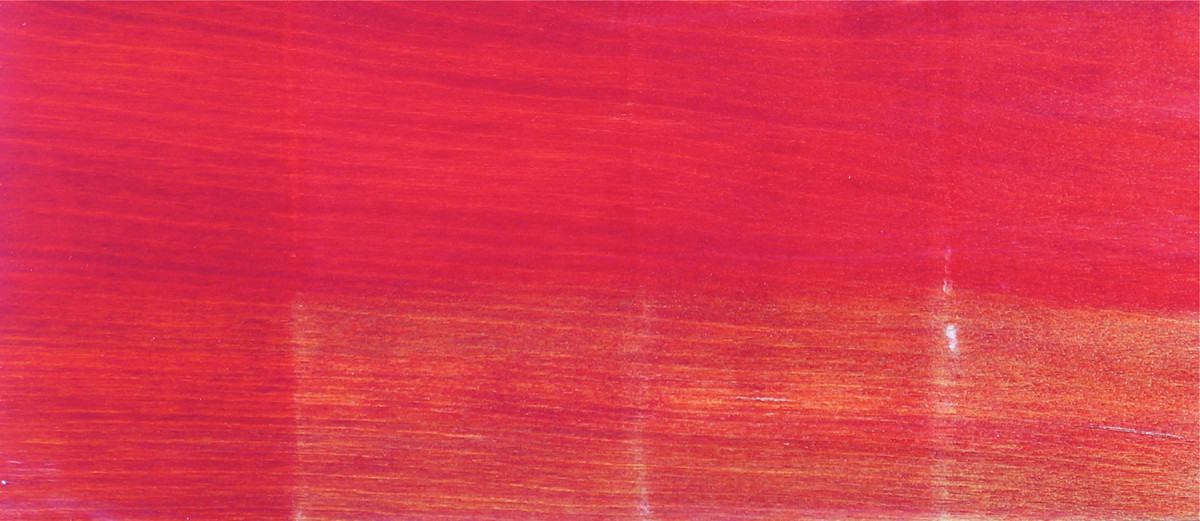

UV-resistance test. To determine if teak oils are effective at preventing penetration of UV rays I applied two coats of all 14 “UV resistant” teak oils in alphabetical order, separated by masking tape, to two panels stained with a red dye. I used red dye because it fades quickly in UV light and speeds the test. I covered the top half of the two panels and placed them in direct sunlight for just 30 hours. Teak oils, which have to be wiped off to be functional, are just too thin to be effective, even if they actually do contain UV absorbers.

Teak is native to the South Asian countries of Myanmar, Thailand, India, Cambodia and Laos, but plantations now exist elsewhere. The wood is prized for its resistance to fungal decay and insects such as termites and marine borers.

Teak also resists decay from sun, rain and saltwater extremely well. As a result, teak has been used for centuries in marine environments, especially on boats. It has also become popular for general outdoor situations, including decks and furniture.

The natural color of teak is tan to medium brown and the grain resembles that of walnut. Upon exposure to UV sunlight and rain or saltwater, unfinished teak, like all woods, turns silvery gray. The cause is the degrading of the color-providing lignin and extractives at the surface, leaving only the cellulose. It’s this loss of color that people hope to prevent by applying a teak-oil finish. They may also think they are extending the life of the teak.

There are three distinct and very different markets for products labeled “teak oil:” exterior wood, primarily boats, decks and outdoor furniture; interior wood, including boat interiors and hardwoods other than teak; and as a furniture polish on already finished interior teak furniture, mostly from Scandinavia.

UV Resistance

Film build. Ultraviolet absorbers alone can’t prevent penetration of UV rays; film thickness is also needed. To demonstrate this, and also compare varnish claims, I finished a red-dyed panel with five brushed coats of four different varnishes and exposed it to sunlight for six months. From the left: Z-Spar, a boat varnish sold at marinas; Minwax Helmsman and Wood Kote Flagship, both marketed as UV-resistant and sold in home centers; and Devoe interior varnish. Z-Spar clearly contains UV absorbers. You have to question the claims of Minwax and Wood Kote because their products performed almost as poorly as interior Devoe varnish on the right.

Fourteen of the 16 teak oils I collected and tested are marketed for boats or outdoor furniture. These products either state specifically “UV resistant” or imply it in the name (“Boat,” “SeaFin,” “Marine” etc.), with a picture or drawing of a boat or garden furniture on the label, or with a marketing claim such as “fights weathering and fading.”

Resistance to UV light in a wood coating is achieved in one of two ways: the inclusion of pigment or the inclusion of a UV absorber (I use the term broadly to include all types). The best example of a UV-resistant pigmented coating is paint. The next best, also in effectiveness, is deck stain.

There are several products sold in stores or online alongside teak oils that resemble a deck stain in that they contain pigment but are too thin, or dry too soft, to be built up like paint. These protect better than teak oils because of the pigment, but they also color the wood, which many people don’t like.

Ultraviolet absorbers work by turning light energy into heat energy, which dissipates. But these absorbers wear out under UV exposure, resulting in the surface first dulling, then cracking if there’s a build. Eventually, the coating degrades to the point that UV rays reach the wood and degrade it, and the coating peels.

To prevent this from happening for the maximum time, boat owners and finishers who want the wood to keep its color typically apply as many as eight brushed or sprayed coats of a UV-resistant, clear film-building finish such as varnish or water-based finish. After six months to two years (depending on latitude and exposure), they sand off the dulled surface finish and apply several more coats.

By following this procedure, the time when the entire finish has to be stripped and replaced can be postponed.

But this is a lot of work. So just as manufacturers of oil finishes have found a market among woodworkers wanting an easy wipe-on, wipe-off finish, manufacturers have also found a market among boat owners and people with outdoor furniture for easy-to-apply oil finishes.

Twelve of the finishes labeled “teak oil” and sold as UV resistant are oil – that is, mineral oil, linseed oil, tung oil or oil/varnish blend. One, First Mate Marine, is wax. One, Briwax, is wiping varnish.

The problem with oil and wax finishes is that they can’t be built up thick enough to be effective. The wood can be re-oiled periodically whenever it begins to fade to put some color back in for a while, but long-lasting results can’t be expected if the wood is exposed to sunlight.

Briwax could be built up, of course, but the directions don’t say to do this, and I saw no evidence of better UV resistance in wiped-off coats.

What’s Really in There?

|

Brands Labeled Teak Oil |

Manufacturer’s Claims |

Contents: From manufacture, or my best guess |

|

Amazon’s Golden |

Interior/exterior/ |

Mineral oil and dehydrated castor oil |

|

Behlen |

For teak and other exotic woods. No exterior claim |

Linseed oil |

|

Boat Armor |

Restores natural oil balance in wood with “mineral seal oil” |

Mineral oil |

|

BoatLIFE |

Adds original oil to protect wood |

Oil/varnish blend |

|

Briwax |

Interior/exterior. Feeds wood |

Wiping varnish |

|

Dalys SeaFin |

Interior/exterior. Won’t chip, crack or peel |

Oil/varnish blend |

|

First Mate Marine |

Interior/exterior. Feeds wood. For teak and all fine woods |

Wax and turpentine |

|

Flag Wood Care |

Interior/exterior. From England. Replaces natural oils |

Probably linseed oil |

|

Interlux Premium |

Traditional Scandinavian blend of oils |

Linseed oil |

|

MaryKate NuTeak |

Extremely long resistance |

Tung oil |

|

Meguiars Gold |

Interior/exterior |

Linseed oil |

|

Minwax |

Interior/exterior. For teak, mahogany and rosewood |

Oil/varnish blend |

|

Scan Care |

From Denmark. |

Probably linseed oil |

|

Star Brite |

Interior/exterior. For teak and other fine woods |

Tung oil |

|

Watco |

Interior/exterior. Protects from inside |

Oil/varnish blend |

|

West Marine Premium Gold |

Interior/exterior. Biodegradable |

Probably linseed oil |

Interior Teak Oils

Pigmented finishes. Alongside the teak oils sold in stores and online are pigmented wipe-on/wipe-off finishes marketed for teak. They don’t call themselves oil, and they market themselves as more UV-resistant than oil, which they are because they contain pigment. The Semco product pictured is the clear version, but pigmented versions also exist, and the company encourages you to buy them. I didn’t find the clear any better than teak oils.

Ten of the teak oils marketed for exterior teak are also marketed for interior teak, including other hardwoods in some cases. Two, Behlen and Scan Care, don’t mention exterior uses.

The quality you would want in an oil marketed for interior teak would be better drying. This could be achieved, for example, by the addition of more driers to counteract the oily resins in teak, which slow the drying.

But the one characteristic that stood out with all the teak oils (not including Briwax, which is varnish), was how slowly they dried on any surface, including glass. Though there’s nothing wrong with using any oil or varnish marketed for exterior use on interior wood whether or not a manufacturer says so, I didn’t notice improved drying.

Furniture Care

Danish teak furniture. The finish used on teak furniture imported from Denmark and other Scandinavian countries is a very durable catalyzed (“conversion”) varnish. It’s applied thin with a flat sheen to resemble an oil finish, and it’s often marketed as oil, but it’s far more protective and durable. This dining table, used for all meals, is 30 years old and is still in good condition.

In the mid-20th century, teak was made popular as an indoor furniture wood by Danish designers and factories. Though the finish on this furniture is commonly marketed as “oil,” it is actually a very durable catalyzed (“conversion”) varnish. The finish typically has a flat sheen and is applied thin so it resembles non-film-building oil to an untrained eye. I have some knowledge of this because I worked in Denmark in the mid-1970s spraying catalyzed varnish on teak.

The Danes may be less-than-honest marketers, but they aren’t fools. They know they can’t hope to create a market for furniture with a soft finish of no measurable thickness that doesn’t prevent liquid penetration. Tabletops finished with oil can look terrible within six months to a year. But the Danes also reason (correctly) that they can take advantage of the mystique of teak as a naturally oily wood and promote the finish as oil.

They can then add to the mystique by selling special “teak oils” to be used as furniture polishes that people believe replace the natural oils in their teak furniture. Note that this would have to occur through the catalyzed varnish that is so good at preventing liquids from penetrating – even if the natural oil could be or needed to be replaced.

Conclusion

Oil-finished teak. Linseed oil, tung oil and oil/varnish-blend finishes darken considerably as they age. Contrast the color of this 20-year-old handmade teak coffee table, finished with Watco Danish Oil, with the still-natural teak color of the dining table at left.

The label “Teak Oil” means nothing. The finish inside could be anything, though all the brands I gathered were limited to oils, varnishes or waxes that thin with petroleum-distillate solvents or turpentine.

Teak oils could legitimately be relabeled “snake oil” for all they have to do with teak wood.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.