We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

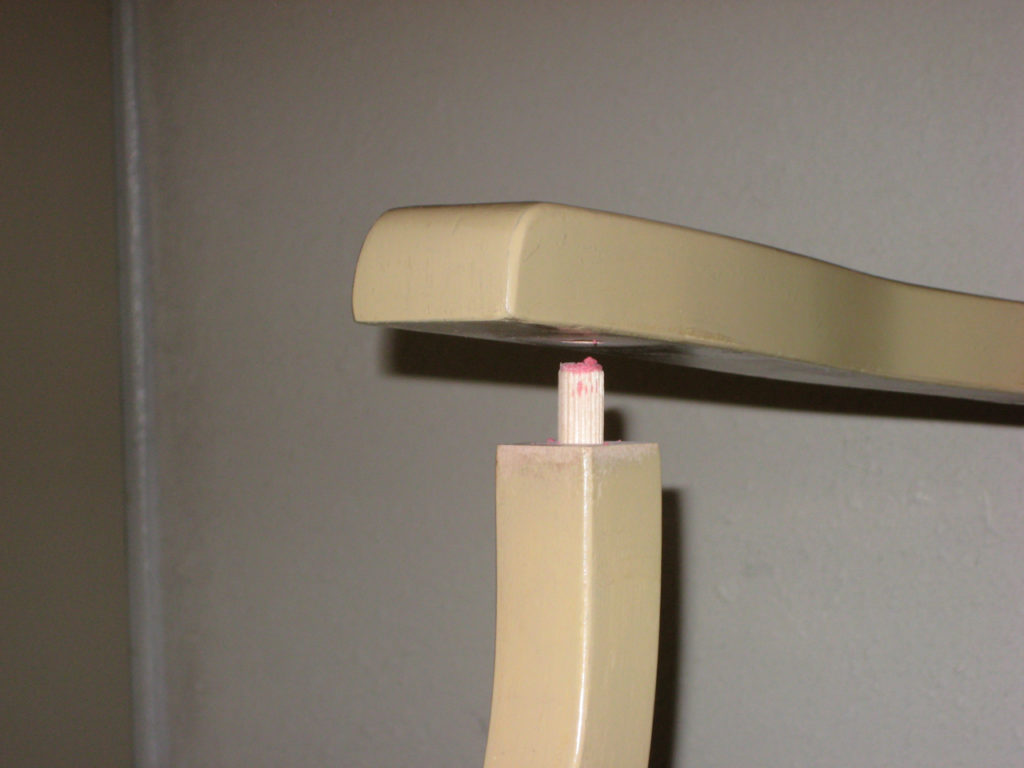

It’s pretty clear why this joint came apart. Most of the dowel and the mortise aren’t coated with glue.

Why does so much factory furniture, made with dowel joinery in the last forty or fifty years, often not hold up well? I have two explanations, both of which are shown in these pictures of chair arms.

The first is that the dowels aren’t coated well with glue. The way gluing on a production line so often works is that a little glue is dropped into the dowel hole as the part moves along the conveyor. Then, when the dowel is inserted, there’s not enough glue to squeeze up and coat the entire dowel. Only the tip of the dowel gets coated.

This dowel and mortise has even less glue on it.

So why don’t manufacturers simply insert more glue so the dowels do get coated? Because they are erring on the light side to be sure there’s no squeeze out that would block stain from penetrating the show surface around the joint. Squeeze out slows production a lot because of the time it takes to remove it and sand the wood smooth. Best to just to avoid it altogether.

The second explanation is the dowels themselves: fluted instead of spiral-grooved. The first principle of gluing is to achieve tight wood-to-wood contact. Said another way, you can’t glue air. So, though fluted dowels might make it easier for glue to squeeze farther up the dowels, there’s very little actual wood-to-wood contact. Most of the area is the recessed “flutes.”

From the left are a spiral-grooved dowel, which I think is the strongest, a fluted dowel, a home-made dowel grooved with the aid of my home-made jig at the top from a dowel rod at the right.

It’s been my experience that spiral-grooved dowels are far better because there’s so much more wood-to-wood contact. Why the spirals at all? Because they allow excess glue to squeeze out when the parts are clamped – that is, to not be trapped at the bottom of hole, which would prevent the dowel from penetrating deep enough.

Even with the spiral grooves, though, the best practice is to coat both the dowels and the sides of the holes with the glue using a brush. Pour some glue into a plastic or glass container, ideally with a lid to keep the glue from drying out, and work from it. Using a brush to coat the surfaces is very fast.

Using a brush to apply glue is much more efficient than a typical spout container.

– Bob Flexner

Brian Boggs shares his technique for strong dowel joints in his video, Accurate Dowel Joints, available on our streaming site for $3.99. It’s a fascinating peek into the world of chair making and green woodworking.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Thank you for the update, Adrain!! I updated the old posts on my website blog. I knew he downsizing production last year but this is the first I’ve heard that production has stopped.

It would be great if someone bought the machinery and made these dowels again. They were in a class by themselves. Yes, I think they made an important difference in dowel joinery.

The Laurier dowels are no more. The guy who made them has retired. He indicated to me that the machinery that makes them is for sale and he’s hoping to find somebody to continue the product. (Just a few are available in weird sizes on his site.)

Note that Lee Valley has switched to Chinese dowel pins, and they indicated to me that the new product has cut flutes, not compressed ones.

Does anybody else make dowels that are grooved by compression rather than cut? Does it really make a difference?

Well, I had a service call this morning to repair a chair, less than a week old, with all the dowel joints coming apart. Fluted dowel pins that appeared to have a glob of glue on the end and little anywhere else. Very similar to the first two photos.

The biggest problem with dowel joints is the dowel and adhesive. I have repaired many chairs with failed joints using threaded steel rod and a good two-part epoxy like West or System 3. Epoxy fills gaps with strength, doesn’t shrink, and bonds to end grain well. Mix in some filler and it won’t run out of a loose joint. I have never had a repair fail.

Would the results be better if the flutes were compressed fibers instead of cut into the dowel. The moisture from the glue would expand the fibers as it cured.

“If good dowel joints aren’t the oldest joints ever made, loose ones must be.” wrote R. Bruce Hoadley ca. 1980. The problem with most strength tests, including ones done by the manufacturers of premium dowel jigs, is that the tests are done soon after gluing, not after a few seasons of moisture variant expansion/contraction.

I took a tour of a cabinet factory a couple of years ago. One machine drilled the holes and inserted the dowels into half the joint. The other half was done by hand just prior to clamping up.

Thanks for your experiments comparing the Laurier dowels with the “made-in-China” dowels. I’d like to see a comparison with spiral-groove dowels. But more important than the type of dowel used is the superior strength produced by coating both the dowel and the hole (mortise) with glue using a brush.

I’ve never understood the point of Titebond III or even Titebond II for that matter. This topic is on my list for the near future.

Bob,

I’ve found Laurier dowels to be clearly the best. They are very consistently and accurately made with helical grooves formed by compression, which expand with water-based glue. They are available from Lee Valley, and directly from Laurier/Just Joinery, located in Canada.

I did some low-tech testing of dowel joinery with different dowels (including Laurier’s) and glues, and wrote about it on my blog here: http://www.rpwoodwork.com/blog/tag/dowel-joinery-looking-inside-series/

Rob P.