We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

“Tricks of the Trade” is one of the most well-liked sections in our magazine. Here are four of these reader-submitted woodworking tips from the many we published last year. Enjoy! And if you like what you see, consider a subscription to the magazine. The content is deep. You’ll learn a ton with each issue.

Tell us some more of your favorite tricks in the comments section at the bottom of this post!

–Dan Farnbach

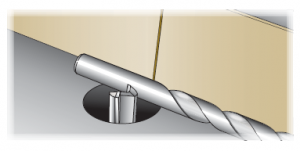

Drill Bit as Set-up Block

Need a quick and precise way to set the fence on your router table, mortiser, drill press table saw or band saw but don’t have those fancy set-up blocks? Yes, you do – your drill bits.

Need a quick and precise way to set the fence on your router table, mortiser, drill press table saw or band saw but don’t have those fancy set-up blocks? Yes, you do – your drill bits.

Just choose the appropriate-size bit and use it as a spacer to set the fence. It also works for setting a precise distance on components of your projects.

Rob Cairns

Nevada City, California

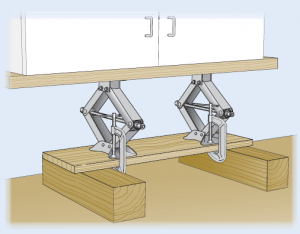

Use Car Jacks in the Shop to Lift and Level

I have long used my car’s scissor jack for house and shop projects. When I needed to install a new set of cabinets in my shop, I realized that a pair of these jacks would be perfect for positioning and leveling them.

I have long used my car’s scissor jack for house and shop projects. When I needed to install a new set of cabinets in my shop, I realized that a pair of these jacks would be perfect for positioning and leveling them.

I clamped both scissor jacks to a scrap piece of 3/4″ stock to provide stability. I also blocked them up so the scissor extension was sufficient to lift the cabinets into position.

Bill Wells

Olympia, Washington

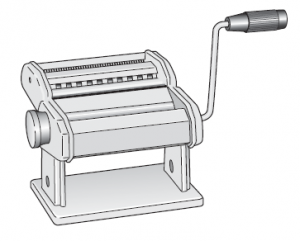

Inlay Stringing the Easy Way

Here is a trick I learned a few years ago from a fellow member of the St. Louis Woodworkers Guild. First, buy a hand-cranked pasta machine. Then run a sheet of veneer through it (not paper-backed veneer). Voila! Instant string inlay! Now just shape a scratch stock blade to match the width and you can add a string inlay border to your piece in very little time.

Here is a trick I learned a few years ago from a fellow member of the St. Louis Woodworkers Guild. First, buy a hand-cranked pasta machine. Then run a sheet of veneer through it (not paper-backed veneer). Voila! Instant string inlay! Now just shape a scratch stock blade to match the width and you can add a string inlay border to your piece in very little time.

Pro Tip: Don’t use your wife’s pasta machine. And don’t spend a lot of money on a brand-new one. You can find them at garage sales.

Ethan Sincox

St. Peters, Missouri

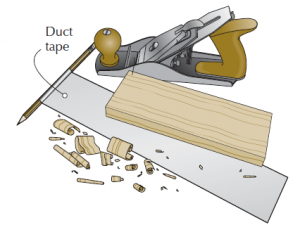

Universal Planing Stop

Last week, I restored a couple old Millers Falls planes for a co-worker. I wanted to give him a quick lesson on how to operate his tools, but in the middle of a bunch of cubicles, workholding is at a premium. So we came up with this quick planing stop, using only a pencil and some duct tape. Wrap the pencil in the tape, then stick it down wherever you need a planing stop. This worked so well, I am sure I will use it on my workbench at home for thin stock.

Last week, I restored a couple old Millers Falls planes for a co-worker. I wanted to give him a quick lesson on how to operate his tools, but in the middle of a bunch of cubicles, workholding is at a premium. So we came up with this quick planing stop, using only a pencil and some duct tape. Wrap the pencil in the tape, then stick it down wherever you need a planing stop. This worked so well, I am sure I will use it on my workbench at home for thin stock.

Trevor Angell

Andover, Kansas

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Often I get a job where I need to quickly cut 20 or 30 plywood circles of differend diameters (10″ to 48″) for product displays on my band saw. I made my own circle cutter. It has a tee track where I can slide the pivot pin in or out from the blade and lock it there for the correct diameter. But cutting the stock so it fits firm, but not too tight, against the blade each time to start the cut is a nusance, I made my circle cutter so it can slide back out of the miter track, but not all the way. I put a stop under the jig so when I slide it in, it stops when the pin is in line, even with the blade. I can then put the slightly oversize stock on the pin when the circle cutter is still retracted, start the saw, slide the circle cutter in while cutting the exact starting point, lock it in place, then start cutting the circle. I get a perfect circle every time.

(I have an 18′” Jet band saw)