We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Can we not agree that I am not of sound mind and body? Yup? OK, read on.

Last year I commissioned blacksmith Peter Ross to make a holdfast for me that was made as close as possible to Andre Roubo’s instructions. Ross is quite familiar with Roubo, but I sent him a translation of the section on holdfasts that a friend did a few years back that also converted the French inches to modern inches.

French inches are longer than modern inches. Click here to read more on that subject.

After some draft drawings, Ross began work on the monster. It was so large he had to hunt especially hard for a piece of iron that was 2-1/2” diameter. Last week, Ross told me the holdfast was complete. He’s going to hand it over while I’m teaching my class on building a tool chest at Roy Underhill’s The Woodwright’s School.

How does the holdfast work? We don’t know.

“I can’t try the thing out – it’s too big,” Ross wrote in an e-mail. “This project was a handful, but came out looking good.”

I couldn’t agree more. I have a lot of ideas about this large-scale holdfast that I’ll share here on the blog when I return from North Carolina. In the meantime, enjoy the following translation of Roubo’s text on holdfasts and the photos from Ross.

— Christopher Schwarz

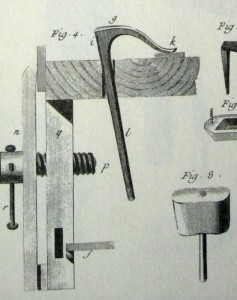

Holdfasts are tools made of iron and are used to hold the work on the bench firmly and stably. They are ordinarily 18” to 20” and even 24” long in the shank; their thickness must be between 12 to 15 (1-1/16” to 1-5/16”) lines, and the curve of their paws is 9” to 10” long by around 10” high. They must be of very soft iron, forged in one piece so they don’t break. All their strength is in their head. That is why we will observe that from the head g to the paw k, they get thinner so that their extremity only has two lines (3/16”) of thickness at the most, which will make them more flexible and increase their pressure.

We must curve them so that when they are tightened they will only grip by the tip of the paw, because if they would carry more pressure in the middle they would ruin the work and hold less firmly.

Moreover, it is easy to see that after long use, the shank of the holdfast will widen the holes of the workbench; and if it didn’t grip well by the tip, before long, it would soon carry all the pressure on the back of the paw and cause the problem I have mentioned above.

Engage the holdfast by hitting it on the head g with a mallet and release the holdfast by hitting the head in the other way, that is on its side and upward or on the side of the shank.

Holdfasts must never be polished because then they will not hold well. They should only be roughed up with a file or stone. Only the paw must be clean and polished so it does not mar the work.

The “leg holdfasts” are not different, other than they are smaller. They hold the wood on its edge along the length of the workbench with the help of the wooden hook m, figure 1. This hook is fastened with screws or strong nails on the front edge of the workbench’s top and is sometimes arrayed with iron points. But because the points often ruin the work, it is best to remove them or to make them like in figure 5 (see the illustration of the hook).

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

As to the old french inches, what difference does it make? Determine the proportions involved and make it in what ever scale you like. Metric or Imperial. I spend much of my time converting a design from visual to actual, regardless of the actual measure. Keep the right proportions and make it any size you like.

See what happens when you leave? They said you’d commissioned a cast-iron holdfast from a blacksmith! Sorry ’bout that Mr Ross, they should know better…

About old French inches.

You must be aware that before the French revolution, the length of an inch would have been different in each village.

Determining the value of Weight and measures was a privilege of the local Lord.

You might be interested in reading:

“The measure of all things.The seven-year odissey and hidden error that transformed the world” by Ken ALDER

Free Press – 2002

especially chapter 5

My great grandfather was an “ébeniste” in Brussels/Belgium at the turn of the 19th/20th century and I have seen holdfast that might have been 2 inches in diameter. They were effectively brittle (don’t ask how I know).

I think it funny that the French inches are bigger.

non, vraiment – c’est six pouces

It’s pretty cool that you had this built but does it work any better than other holdfasts on the market? I have a set of grammercy holdfasts that I have yet to budge, even more so after I made a pair of blocks with leather glued to the face to act as pads. And, not to brag, but at 6ft 200lbs I’m hardly little, or weak for that matter. Just curious.

Wait! Where’s m and figure 1??? And figure 5??? Arrgghh, not again. Please hurry dear DW!!

So, what your saying is size does matter?

Well, if King Kong ever takes up woodworking ….

http://books.google.com/books?id=BNGE4D70TyYC&pg=PA20&lpg=PA20&dq=rob+tarule+workbench&source=bl&ots=HWfHyCKNpa&sig=-6fjqujWP7pjkrYkk0epJ2EFqiI&hl=en&sa=X&ei=6wU9T-_vG-qK2wWno5izCA&ved=0CEQQ6AEwAQ#v=onepage&q=rob%20tarule%20workbench&f=false

1 1/16th diameter octagonal shank with 15 and 20

shank lengths

It’s a monster, for sure!

Chris, you may want to mail that beast back to N. Kentucky, via flate rate priority mail! Also, you may want to prepare yourself for the derision from Roy, regarding the apparent lack of stoutness of your bench – he’ll likely chide you that the French Beast Holdfast will do more damage to your Roubo than he ever did.

I live in France and just built a bench. I found a couple of holdfasts at a local antique dealer. They are almost that size, 1″ by maybe 18″ in the shank with a reach of 6″-7″ in the paw. The dealer told me that traditionally they were custom ordered by the carpenter that made the bench for that bench. Not easy to find today, because normally you need to buy the bench with them 🙂 or find somebody that tossed an old rotten bench, but didn’t sell the holdfast to an iron monger.

There are a couple on Ebay.fr

http://cgi.ebay.fr/OUTIL-ANCIEN-valet-de-menuisier-ebeniste-charpentier-/250911082803?pt=FR_JG_Art_Objets_XIX&hash=item3a6b774933

you could keep that thing next to your bed in case you have a burglar. One smack with that and they’ll be out.

how much does that thing weigh?

Woah!

Mon Dieu! What will that need, an inch-and-a-half hole in the bench top? You’ll be losing your block plane down there. That’s an enormous piece of iron. If it doesn’t work out as a holdfast, make sure you save it, in case you ever get a boat.

I have two holdfasts from Peter, in two different styles, as well as a name stamp. He does excellent work.